| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

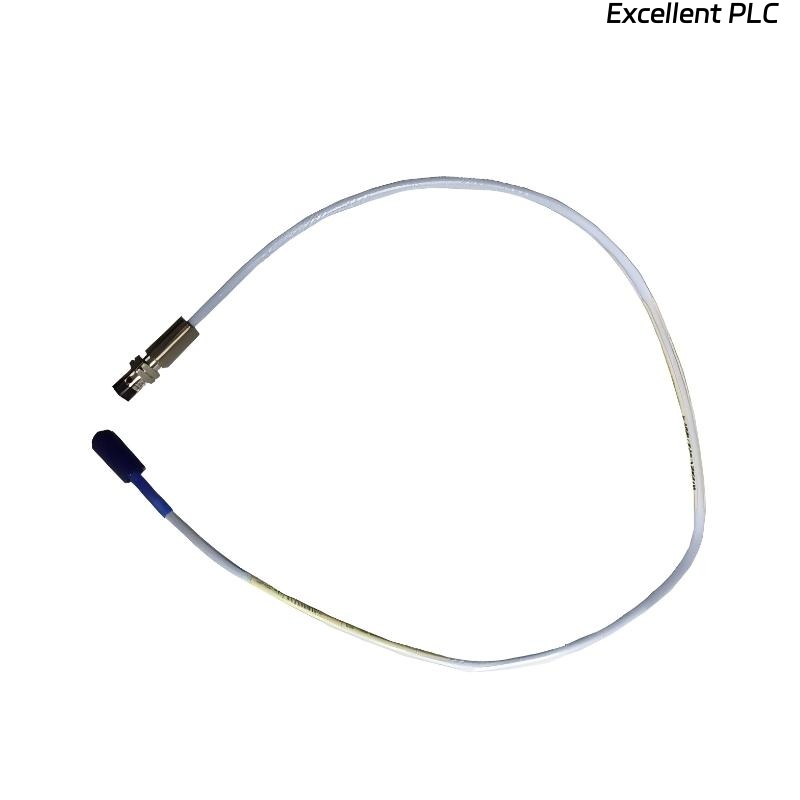

The Bently Nevada 330106-05-30-02-CN 3300 XL 8 mm Reverse Mount Probe is a high-precision, non-contact eddy current sensor developed to deliver reliable displacement and vibration measurements in critical rotating machinery. As part of the 3300 XL series, this probe represents the latest evolution in Bently Nevada’s proximity sensing technology, offering enhanced mechanical robustness, electrical stability, and long-term accuracy even under harsh industrial environments.

The reverse-mount design allows installation from the rear side of the machine housing or bracket, providing a cleaner installation path and better protection against mechanical damage and oil contamination. Engineered to meet the demanding requirements of turbomachinery monitoring, the 330106-05-30-02-CN probe ensures optimal performance when integrated with Bently Nevada’s Proximitor sensors and 3500 Monitoring Systems.

Technical Specifications

| Parameter | Description |

|---|---|

| Model Number | 330106-05-30-02-CN |

| Series | 3300 XL 8 mm Reverse Mount Probe |

| Measurement Principle | Eddy current, non-contact displacement measurement |

| Probe Tip Diameter | 8 mm |

| Linear Range | 2.0 mm (80 mils) |

| Sensitivity | 7.87 V/mm (200 mV/mil) |

| Frequency Range | DC to 10 kHz |

| Accuracy | ±0.25% of full-scale |

| Operating Temperature Range | -35°C to +177°C |

| Storage Temperature Range | -55°C to +200°C |

| Temperature Coefficient | ≤ ±5% over full range |

| Probe Material | AISI 303 stainless steel |

| Mounting Configuration | Reverse mount (rear installation) |

| Mounting Thread | M10x1 or 3/8-24 UNF |

| Cable Type | Coaxial, PTFE insulated |

| Connector Type | ClickLoc™ quick-connect |

| Environmental Protection | IP67 (dust-tight and oil-resistant) |

| Vibration Limit | 196 m/s² (20 g), 0–2000 Hz |

| Shock Limit | 5000 m/s² (500 g) peak, 1 ms duration |

| Power Supply | Via 3300 XL Proximitor Sensor |

| Output Signal | DC voltage proportional to gap/displacement |

| Electrical Isolation | Fully isolated internal shielding |

| Compliance Standards | CE, RoHS |

| Total Length | Optional |

| Weight | 0.323 kg |

Product Applications

The Bently Nevada 330106-05-30-02-CN Reverse Mount Probe is widely used in the condition monitoring and protection systems of rotating and reciprocating machinery. Its versatility and robust design make it suitable for multiple applications, including:

-

Gas and Steam Turbines – Monitoring shaft vibration, axial displacement, and bearing clearances.

-

Compressors – Detecting imbalance, shaft misalignment, and bearing degradation.

-

Motors and Generators – Measuring shaft runout, position, and vibration amplitude.

-

Pumps and Fans – Tracking rotating shaft conditions to prevent failure.

-

Gearboxes and Industrial Drives – Assessing gear mesh alignment and lubrication conditions.

-

Petrochemical and Refinery Machinery – Providing reliable data for predictive maintenance programs.

Its reverse-mount construction minimizes exposure to contaminants and physical damage, offering high reliability even in environments with oil, dust, or high mechanical stress.

Product Advantages

The 330106-05-30-02-CN probe combines the best aspects of durability, precision, and compatibility. Its enhanced design ensures long-term stability and system integrity for continuous machinery monitoring operations.

-

Reverse-Mount Flexibility – Enables secure installation from behind the mounting surface, ideal for space-constrained or high-vibration applications.

-

Superior Accuracy – Maintains measurement precision across a wide temperature and vibration range.

-

Rugged Construction – Stainless steel housing and hermetic sealing protect against moisture, oil, and corrosion.

-

Electromagnetic Noise Immunity – Coaxial cable shielding minimizes interference in electrically noisy environments.

-

Full 3300 XL Compatibility – Seamless integration with Proximitor sensors and extension cables.

-

Extended Operating Temperature Range – Ensures reliable function in both cryogenic and high-temperature machinery environments.

-

Stable Linear Response – Provides consistent output across the calibrated measurement gap.

-

Low Maintenance Requirement – Factory calibrated and sealed for long-term use without recalibration.

-

Versatile Industrial Use – Applicable in turbines, compressors, and motors across various industries.

-

Trusted Performance – Part of Bently Nevada’s globally proven 3300 XL line, ensuring reliability in mission-critical systems.

FAQ

-

How does the 330106-05-30-02-CN differ from a standard forward-mount probe?

The reverse mount version installs from the rear of the mounting structure, reducing exposure to oil or debris and improving probe protection in high-vibration environments. -

What sensing principle does this probe use?

It uses the eddy current principle, detecting changes in the electromagnetic field between the probe tip and a conductive target to determine displacement or vibration. -

Can the probe be connected to any Bently Nevada Proximitor sensor?

Yes. It is fully compatible with 3300 XL Proximitor sensors and extension cables designed for 8 mm probes. -

What is the effect of temperature variation on the probe signal?

The probe is temperature-compensated, maintaining accuracy within ±5% across its full operational temperature range. -

Is the 330106-05-30-02-CN suitable for use in high-vibration applications?

Yes. It withstands continuous vibrations up to 20 g and short-term shocks up to 500 g, making it ideal for high-speed rotating equipment. -

How is electrical noise minimized in this system?

The probe features an internally shielded coaxial cable that minimizes electromagnetic interference and ground loop effects. -

What kind of materials can the probe measure?

It is calibrated for conductive materials, typically AISI 4140 steel, and can measure displacements relative to any ferromagnetic target. -

Can this probe be used in hazardous areas?

When used with certified Proximitor sensors, the system can meet ATEX or CSA requirements for hazardous industrial environments. -

What is the recommended probe gap for optimal measurement?

The nominal probe-to-target gap is approximately 1.0 mm, adjusted during installation for optimal signal output. -

How does cable length affect system calibration?

Each probe and cable assembly is factory-calibrated as a matched system; using non-matching cable lengths can affect sensitivity and linearity.

Related Models (Same Series)

| Model Number | Description | Cable Length | Weight |

|---|---|---|---|

| 330106-05-05-02-CN | 3300 XL 8 mm Reverse Mount Probe | 5 m | 0.323 kg |

| 330106-05-10-02-CN | 3300 XL 8 mm Reverse Mount Probe | 10 m | 0.323 kg |

| 330106-05-15-02-CN | 3300 XL 8 mm Reverse Mount Probe | 15 m | 0.323 kg |

| 330106-05-20-02-CN | 3300 XL 8 mm Reverse Mount Probe | 20 m | 0.323 kg |

| 330106-05-25-02-CN | 3300 XL 8 mm Reverse Mount Probe | 25 m | 0.323 kg |

| 330106-05-35-02-CN | 3300 XL 8 mm Reverse Mount Probe | 35 m | 0.323 kg |

Popular Models from the Same Brand (Bently Nevada)

| Model Number | Product Description | Type | Weight |

|---|---|---|---|

| 3300/12-01-20-01 | AC Power Supply Module | Power Supply | 1.0 kg |

| 330103-05-10-02-00 | 3300 XL 8mm Proximity Probe | Proximity Probe | 0.323 kg |

| 3500/22M | Transient Data Interface | Monitoring Module | 0.85 kg |

| 3500/42M | Proximitor/Seismic Monitor | Vibration Monitor | 0.90 kg |

| 3500/33 | 16-Channel Relay Module | Relay Module | 0.95 kg |

| 330180-91-00 | 3300 XL Extension Cable | Extension Cable | 0.20 kg |

Excellent PLC

Excellent PLC