| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

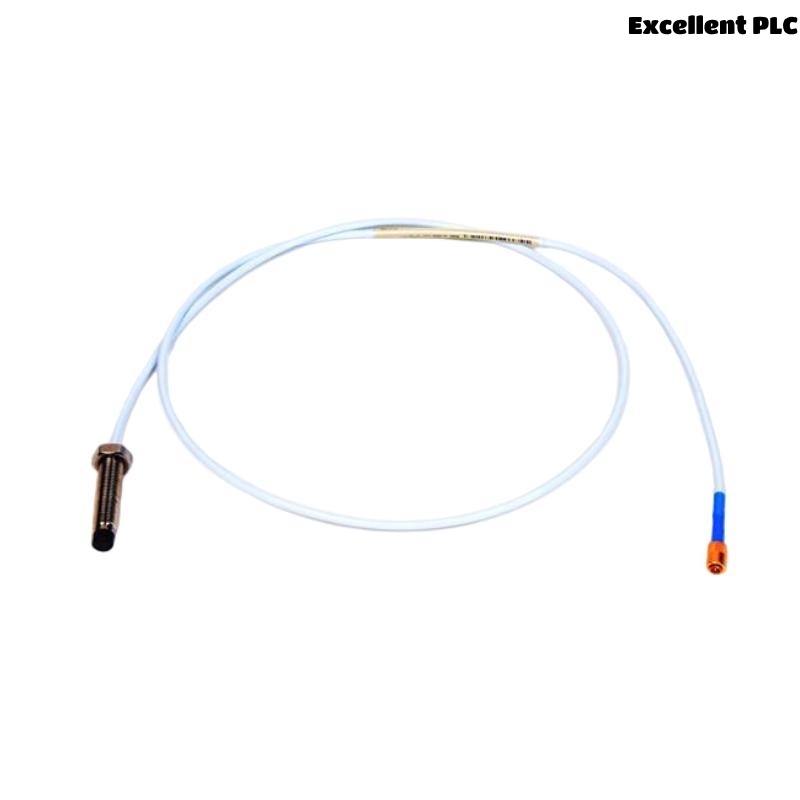

The Bently Nevada 330106-05-30-05-02-CN 3300 XL 8mm Reverse Mounting Probe is a high-precision vibration sensor designed to monitor the health and condition of critical rotating machinery. As part of the renowned 3300 XL series, it provides unmatched reliability and performance in demanding industrial environments.

This particular model features an 8mm diameter and is designed with a reverse mounting configuration, which allows for flexible and easy installation in areas where standard mounting options might be difficult. The 330106-05-30-05-02-CN probe is built to meet the highest standards for durability, accuracy, and operational stability, even under extreme operational conditions.

The probe is widely used in conjunction with Bently Nevada’s 3300 XL machinery protection and monitoring systems, providing accurate vibration data to help prevent unexpected failures and optimize machine performance. With a total length of 0.5 meters and weighing just 0.162 kg, this probe is compact yet highly effective, offering excellent versatility for a wide range of industrial machinery applications.

Product Specifications

| Parameter | Description |

|---|---|

| Model | 330106-05-30-05-02-CN |

| Type | 3300 XL 8mm Reverse Mounting Probe |

| Total Length | 0.5 meter |

| Weight | 0.162 kg |

| Diameter | 8 mm |

| Material | Stainless steel with high-grade insulating materials |

| Mounting Type | Reverse mounting |

| Temperature Range | -40°C to +85°C |

| Frequency Range | 0.1 to 10,000 Hz |

| Vibration Sensitivity | High sensitivity for precise measurement |

| Application Compatibility | Compatible with Bently Nevada’s 3300 XL monitoring systems |

| Certifications | CE, UL, RoHS compliant |

| Protection Class | IP67 (dustproof and waterproof) |

Product Applications

The Bently Nevada 330106-05-30-05-02-CN 3300 XL 8mm Reverse Mounting Probe is ideal for applications requiring high-precision vibration monitoring in critical machinery systems. Its compact size, combined with high durability and sensitivity, makes it suitable for a wide range of industrial applications, including:

-

Turbine Monitoring: The probe is used in turbines for precise vibration measurement, ensuring early detection of potential mechanical issues such as misalignment or imbalance.

-

Compressor Vibration Monitoring: It is a key component for continuous monitoring of compressors, helping identify early signs of damage or performance degradation.

-

Pump Condition Monitoring: The probe is widely used in water treatment plants, chemical plants, and other industries to monitor pumps and ensure their efficient operation.

-

Rotating Machinery: The probe helps track the health of rotating machinery, offering real-time data to detect faults like bearing wear, shaft misalignment, or imbalance.

-

Industrial Motor Systems: In motor-driven systems, the 3300 XL probe helps detect vibration anomalies, reducing the risk of unplanned downtime.

-

Centrifugal Machines: The probe is used in centrifugal machines to measure vibrations, ensuring the early identification of any malfunctions.

-

Manufacturing Equipment: For monitoring critical manufacturing machinery, this probe helps prevent damage and downtime by detecting potential issues before they escalate.

-

Automated Industrial Systems: Integrated into automated monitoring systems, this probe ensures reliable data collection for continuous condition monitoring of machinery.

Product Advantages

-

Reverse Mounting Capability: The probe’s reverse mounting configuration offers greater flexibility for installation in restricted spaces where traditional mounting methods may not be feasible.

-

High Sensitivity: With a diameter of 8 mm, the probe provides high sensitivity for detecting even the smallest vibrations, ensuring early fault detection.

-

Durable Construction: Constructed from stainless steel and high-quality insulating materials, the probe is designed to withstand harsh industrial environments, including exposure to extreme temperatures and mechanical stress.

-

Wide Frequency Range: The probe covers a frequency range of 0.1 to 10,000 Hz, allowing it to detect a wide range of vibration frequencies, from low-frequency imbalances to high-frequency mechanical faults.

-

Compact and Lightweight Design: The 0.5-meter total length and 0.162 kg weight make this probe compact and easy to install in tight spaces while maintaining high performance.

-

Temperature Range: The probe operates reliably within a temperature range of -40°C to +85°C, making it suitable for use in both high- and low-temperature environments.

-

IP67 Protection Rating: The IP67 rating means the probe is fully protected against dust and can withstand immersion in water, ensuring reliable operation in challenging industrial settings.

-

Compatibility with Bently Nevada Systems: The probe integrates seamlessly with Bently Nevada’s 3300 XL machinery protection systems, enabling efficient vibration monitoring and fault detection.

-

Prevents Equipment Failures: By providing real-time vibration data, the probe helps prevent equipment failures and unplanned downtime, saving on maintenance costs and extending the life of machinery.

-

Ease of Installation: Its lightweight and compact design simplify installation and maintenance processes, even in hard-to-reach areas.

Frequently Asked Questions (FAQ)

-

What is the purpose of the Bently Nevada 330106-05-30-05-02-CN probe?

The probe is used to monitor the vibration levels of critical industrial machinery, providing real-time data for predictive maintenance and fault detection. -

What is the total length of the 3300 XL 8mm Reverse Mounting Probe?

The probe has a total length of 0.5 meters. -

What is the weight of the probe?

The probe weighs 0.162 kg, making it lightweight and easy to handle during installation. -

What is the temperature range for the Bently Nevada 330106-05-30-05-02-CN probe?

The probe operates within a temperature range of -40°C to +85°C. -

What is the frequency range of the probe?

The probe has a frequency range of 0.1 to 10,000 Hz, which allows for detection of both low and high-frequency vibrations. -

How is the 3300 XL 8mm Reverse Mounting Probe mounted?

This probe features a reverse mounting design, making it suitable for installation in tight spaces where traditional mounting options may not be practical. -

What types of machinery can this probe be used on?

The probe is used on turbines, compressors, pumps, motors, centrifugal machines, and other types of rotating machinery for vibration monitoring. -

Is this probe compatible with other Bently Nevada monitoring systems?

Yes, the probe is compatible with Bently Nevada’s 3300 XL monitoring systems, ensuring seamless integration into machinery health management systems. -

What certifications does the 3300 XL probe have?

The probe is certified CE, UL, and RoHS, ensuring it meets international standards for safety and environmental compliance. -

What protection rating does the 3300 XL probe have?

The probe has an IP67 protection rating, meaning it is dustproof and waterproof, ensuring it operates reliably in harsh industrial environments.

Recommended Related Models (Same Series or Related)

| Model | Description | Notes |

|---|---|---|

| 330106-05-30-05-02-00 | 3300 XL 8mm Reverse Mounting Probe | Similar model with a slightly different length |

| 330105-05-30-05-02-CN | 3300 XL 4mm Reverse Mounting Probe | Smaller diameter for tighter spaces |

| 330107-05-30-05-02-00 | 3300 XL 10mm Reverse Mounting Probe | Larger diameter for high-vibration systems |

| 330104-05-30-05-02-CN | 3300 XL 5mm Reverse Mounting Probe | Compact probe for smaller applications |

| 330110-05-30-05-02-CN | 3300 XL 8mm Standard Mounting Probe | Standard mounting for conventional installations |

| 330108-05-30-05-02-CN | 3300 XL 8mm Axial Mounting Probe | Axial mounting for specific applications |

Popular Bently Nevada Models (Same Brand)

| Model | Features | Application Areas |

|---|---|---|

| 330106-05-30-05-12-CN | Shielded cable, China version, durable | Vibration monitoring, industrial sensors |

| 330106-05-30-10-00-00 | Standard cable, high flexibility | Machinery diagnostics, automation |

| 330106-05-30-10-02-00 | Extended length, enhanced insulation | Process equipment, control panels |

| 330106-05-30-05-00-00 | Compact build, general-purpose use | Embedded systems, panel wiring |

| 330106-05-30-05-02-00 | High signal integrity, factory standard | Rotating equipment, monitoring |

| 330106-05-30-10-05-CN | Heavy-duty jacket, China region spec | Harsh environments, field devices |

Excellent PLC

Excellent PLC