| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

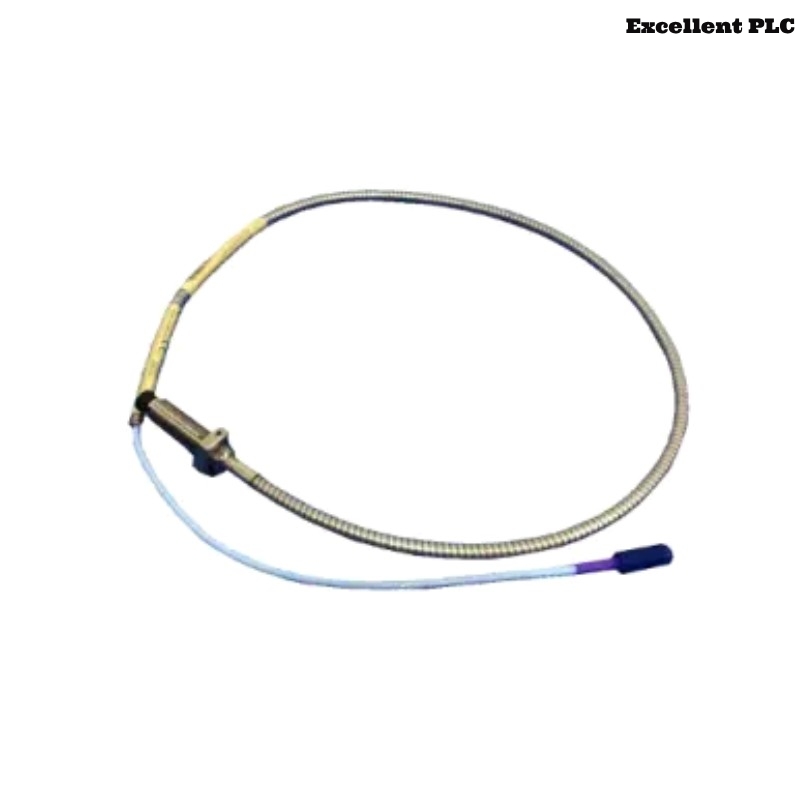

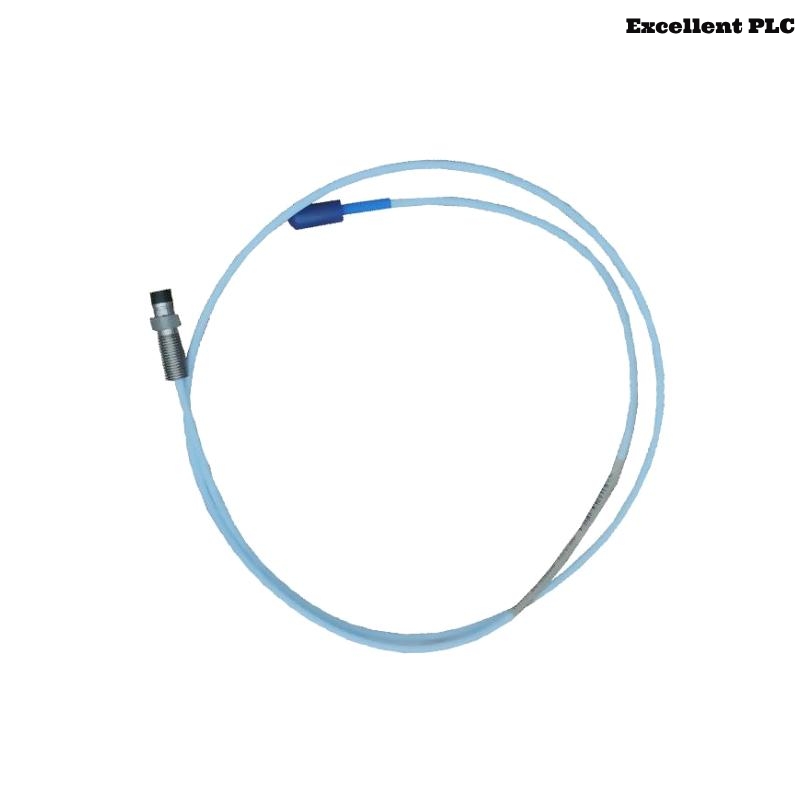

The Bently Nevada 330171-00-12-05-02-00 is a high-precision proximity probe that is part of the globally trusted 3300 XL series, designed for long-term, reliable monitoring of critical rotating machinery. As a 5 mm reverse mount proximity probe, it is engineered for applications requiring installation from the rear of the mounting surface, offering enhanced flexibility in compact or restricted-access spaces.

This model is widely used for non-contact vibration and position monitoring in turbines, compressors, pumps, and other heavy-duty rotating equipment. Its robust construction, high temperature resilience, and compatibility with Bently Nevada’s 3300 XL Proximitor® Sensor make it a top-tier solution for condition-based monitoring in mission-critical environments such as oil & gas, petrochemicals, and power generation.

The 330171-00-12-05-02-00 probe includes is API 670 compliant, and meets the highest standards of linearity, durability, and electromagnetic immunity.

Technical Specifications

| Parameter | Details |

| Part Number | 330171-00-12-05-02-00 |

| Product Family | 3300 XL Series |

| Sensor Type | Proximity Probe (Reverse Mount) |

| Tip Diameter | 5 mm |

| Mounting Thread Size | 1/4-28 UNF |

| Total Length | 0.5 meters |

| Compatible Proximitor | 3300 XL Proximitor® Sensor |

| Measurement Range | 0.25 mm to 2.00 mm (10 mils to 80 mils) |

| Sensitivity | 7.87 mV/μm (200 mV/mil) typical |

| Linear Range | 2 mm (80 mils) |

| Frequency Response | 0 Hz to 10 kHz |

| Operating Temperature | -35°C to +177°C (-31°F to +351°F) |

| Shock Limit | 100 g peak |

| Vibration Limit | 10 g peak (55–500 Hz) |

| Insulation Resistance | >10 MΩ (probe body to connector) |

| Electrical Connector | Coaxial stainless steel overbraid, sealed |

| Material – Probe Body | 303 Stainless Steel |

| Material – Cable Jacket | FEP (Fluorinated Ethylene Propylene) |

| Environmental Protection | IP65 or better (with proper installation) |

| Compliance | API 670, CE, RoHS |

| Weight | 0.161 kg |

Applications

The 330171-00-12-05-02-00 is designed for industrial environments where accurate, real-time vibration and position data is essential for machine protection and diagnostics. Common application areas include:

-

Steam & Gas Turbines

-

Centrifugal Compressors

-

Electric Motors and Alternators

-

Multistage Pumps and Fans

-

Gearboxes and Blowers

-

Critical Skid-Mounted Equipment

-

Wind Turbines and Industrial Drives

-

Marine Propulsion Systems

It is ideal for OEM system integration, retrofitting, and remote installations in harsh industrial settings.

Product Advantages

-

Reverse Mount Design

Simplifies installation in tight or sealed equipment locations. -

API 670 Compliant

Fully meets stringent industry requirements for protection systems in rotating machinery. -

Extended Cable Length

12 ft integral cable allows flexible routing in large machinery layouts. -

Superior Signal Accuracy

Exceptional linearity and sensitivity for dependable measurement of shaft dynamics. -

High Temperature Operation

Functions reliably in environments up to 177°C, ensuring performance in turbine housings or hot zones. -

Electromagnetic Shielding

Coaxial stainless steel overbraid ensures signal integrity in electrically noisy environments. -

Robust Construction

Built to survive continuous operation under shock and vibration loads. -

Seamless Compatibility

Works with all Bently Nevada 3300 XL extension cables and proximitor systems.

Recent Industry News Headlines

-

“Bently Nevada Enhances XL Probe Range for Extended Reliability in Harsh Environments”

-

“New API 670 Guidelines Reinforce Importance of Precision Proximity Monitoring”

-

“Energy Sector Investing in Predictive Maintenance with XL Series Sensors”

-

“Reverse Mount Sensors Improve Maintenance Access in OEM Skids”

-

“GE Bently Nevada Announces Expansion of XL Sensor Production Facilities”

-

“OEMs Favor Compact XL Probes for Modular Machine Design”

-

“Advances in Shaft Monitoring Fuel Demand for XL 5 mm Probes”

-

“Bently Nevada Highlights Cable Armor Tech in Hazardous Locations”

Frequently Asked Questions (FAQ)

-

What is the specific use case of this 330171 model?

It is used for measuring shaft vibration and axial or radial position in rotating equipment. -

Why choose a 12 ft cable version?

The 12 ft cable provides routing flexibility, especially in large machinery with remote proximitor locations. -

How is a reverse mount probe installed?

It is inserted from the rear of the mounting plate or bracket, typically secured with locking nuts or clamps. -

Does it work with extension cables?

Yes, it is compatible with Bently Nevada 3300 XL extension cables. -

What’s the function of the stainless-steel overbraid?

It shields the signal cable from electromagnetic interference (EMI), ensuring accurate readings. -

Can this probe operate at high temperatures?

Yes, it operates up to +177°C, making it suitable for turbine and compressor applications. -

What standards does it comply with?

It complies with API 670, CE directives, and RoHS environmental standards. -

Is calibration required after installation?

Factory-calibrated, but users are recommended to verify calibration annually for critical systems. -

How does it compare to an 8 mm probe?

5 mm probes are more compact and ideal for smaller shaft diameters or tight mounting zones. -

What kind of machinery is best suited for this probe?

It’s suitable for turbines, compressors, pumps, gearboxes, and any critical rotating asset.

Recommended Related Models (Same Series or Function)

| Model Number | Description | Mount Type | Cable Length | Application |

| 330171-00-08-90-01-05 | 5 mm Reverse Mount, High Temp Variant | Reverse | 8 ft | High Temp Compressors |

| 330171-00-05-10-02-00 | 5 mm Reverse Mount Standard Probe | Reverse | 5 ft | Skid Systems |

| 330101-00-10-10-02-00 | 8 mm Forward Mount Probe | Forward | 10 ft | Large Motors & Generators |

| 330104-00-12-10-02-00 | Armored Cable 8 mm Probe | Forward | 12 ft | High EMI Locations |

| 330130-040-00 | NSv Probe (Miniature Probe) | Forward | 4 m | Small Machinery |

| 330178-50-05 | Armored Extension Cable | Cable | 5 m | Harsh Environments |

| 330180-91-05 | Standard Extension Cable | Cable | 5 m | Flexible Routing |

| 330106-05-30-10-02-00 | Terminal Mount Probe for OEM Integration | Terminal Mount | 5 ft | Custom Machine Designs |

Popular Models from Bently Nevada

| Model Number | Description | Product Type | Key Function |

| 3500/22M-01-01-00 | Transient Data Interface Module | Data Interface | Gateway for System Communication |

| 3500/42M-01-00 | Proximitor Monitor (2-Channel) | Monitor Module | Shaft Vibration Monitoring |

| 3500/15-05-01-00 | Power Supply Module | Power Module | Powers 3500 Monitoring System |

| 3500/05-01-01-00-00-01 | System Rack Frame | Hardware Enclosure | Houses Bently 3500 Modules |

| 330103-00-10-10-02-00 | 8 mm Forward Mount Probe | Sensor | General Machinery Monitoring |

| 330104-00-18-10-02-00 | Armored 8 mm Probe | Sensor | Harsh Industrial Applications |

| 3500/20-01-02-00-00 | Display Interface Module | Display Unit | Local Monitoring Screen |

| 330180-50-05 | Coaxial Extension Cable | Signal Cable | Probe to Proximitor Connectivity |

Excellent PLC

Excellent PLC