| Company Information | ||||||||

| sales@xmjzjsgs.com | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

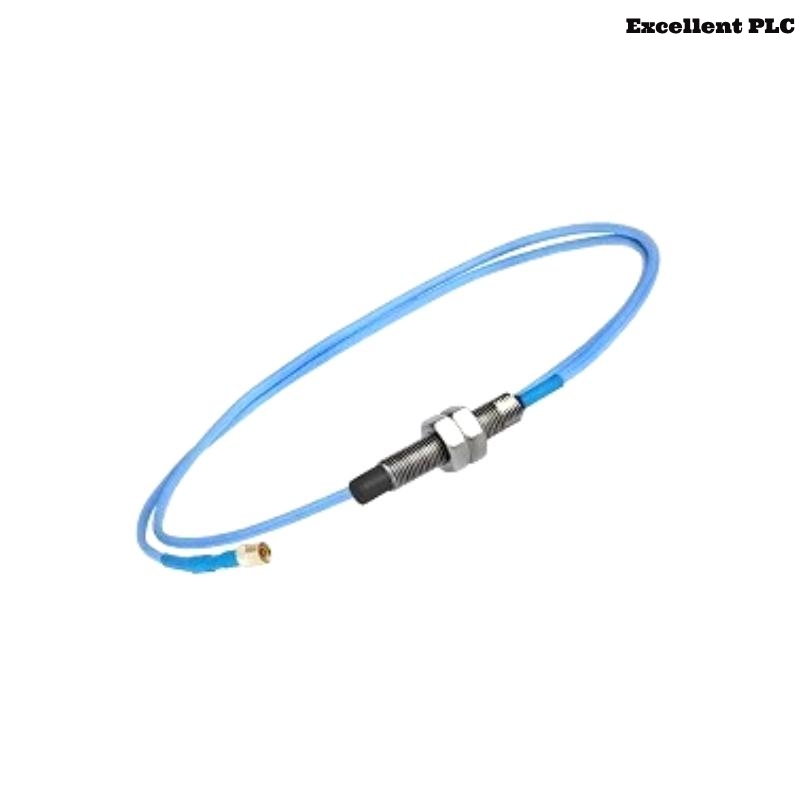

The Bently Nevada 330171-00-26-10-02-00 is part of the 3300 XL series of 5 mm proximity probes, specifically designed for high-precision vibration and position monitoring of critical rotating machinery. This model excels in harsh industrial environments, such as turbines, compressors, and pumps, where reliable, non-contact measurement of shaft displacement is essential. The reverse mount feature of the probe allows for easier installation and maintenance, especially in confined or challenging spaces.

This probe is compatible with Bently Nevada’s 3300 XL Proximitor® Sensors, forming a complete system for condition-based monitoring of machinery. Its durability and accuracy make it an essential component in the proactive management of plant assets, reducing downtime and preventing costly breakdowns by providing real-time vibration data.

With a measurement range from 0.25 mm to 2.00 mm, and an operating temperature range of -35°C to +177°C, the 330171-00-26-10-02-00 probe is engineered for flexibility and performance in demanding industrial settings. Its designed for easy installation and extended reach, providing further convenience for users in large or complex setups.

Technical Specifications

| Parameter | Details |

| Part Number | 330171-00-26-10-02-00 |

| Product Family | 3300 XL Series |

| Probe Type | 5 mm Proximity Probe (Reverse Mount) |

| Mounting Thread Size | 1/4-28 UNF |

| Total Length | 1 meters |

| Measurement Range | 0.25 mm to 2.00 mm (10 mils to 80 mils) |

| Sensitivity | 7.87 mV/μm (200 mV/mil) typical |

| Linear Range | 2 mm (80 mils) |

| Frequency Response | 0 Hz to 10 kHz |

| Operating Temperature | -35°C to +177°C (-31°F to +351°F) |

| Shock Limit | 100 g peak |

| Vibration Limit | 10 g peak (55–500 Hz) |

| Insulation Resistance | >10 MΩ (probe body to connector) |

| Material – Probe Body | 303 Stainless Steel |

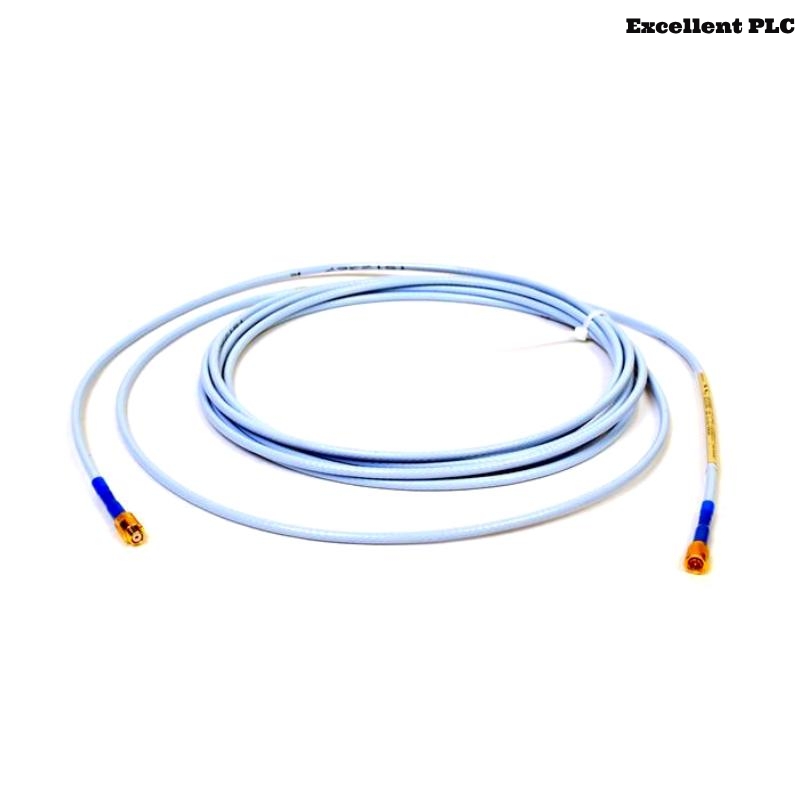

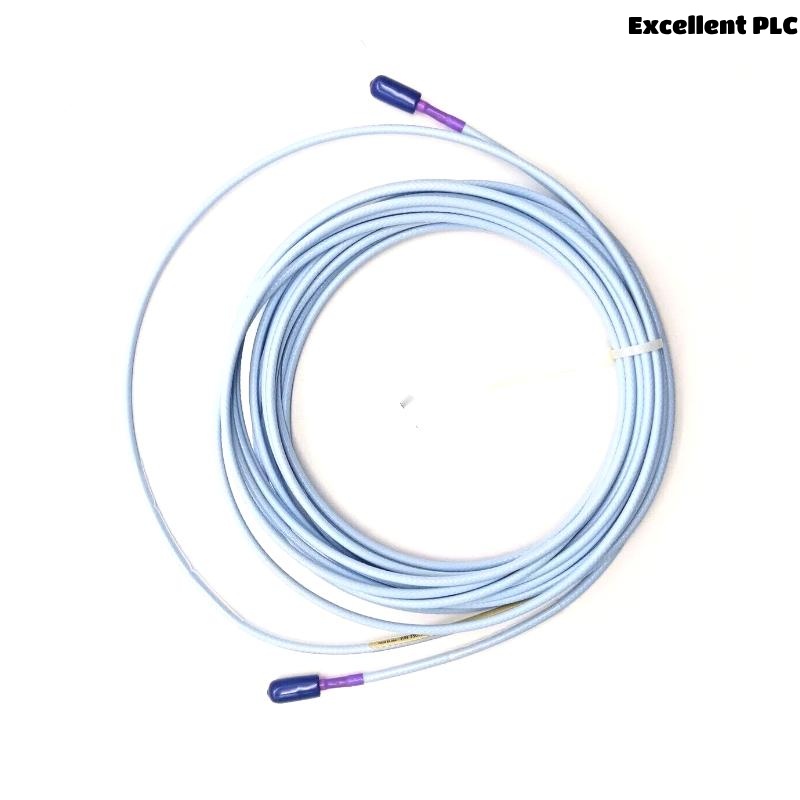

| Material – Cable Jacket | FEP (Fluorinated Ethylene Propylene) |

| Electrical Connector | Coaxial stainless steel overbraid, sealed |

| Environmental Protection | IP65 or better (with proper installation) |

| Weight | 0.323 kg |

Applications

The 330171-00-26-10-02-00 probe is ideal for non-contact monitoring of rotating machinery in a wide range of applications, including:

-

Steam and Gas Turbines

Monitoring shaft displacement for early detection of imbalance or misalignment. -

Compressors and Pumps

Detecting excessive vibration or position shifts in critical pump and compressor units. -

Electric Motors

Tracking the position of motor shafts for predictive maintenance. -

Gearboxes

Ensuring proper alignment and condition of gear shafts. -

Blowers and Fans

Monitoring rotor vibrations to prevent potential damage. -

Industrial Skids and OEM Equipment

Providing real-time monitoring for system integrators and custom installations.

The reverse mount feature makes this probe particularly suitable for installations where access is limited, such as retrofits or when adapting to older systems.

Product Advantages

-

Easy Installation

The reverse mount design allows for flexible and simplified installation, especially in restricted spaces. -

Superior Performance

Offers exceptional linearity, sensitivity, and frequency response, providing highly accurate measurements for critical machinery. -

Wide Operating Temperature Range

The probe can operate in temperatures ranging from -35°C to +177°C, making it suitable for a variety of industrial conditions. -

Electromagnetic Shielding

The stainless steel overbraid and coaxial cable construction ensure minimal interference from electromagnetic noise, leading to reliable data even in electrically noisy environments. -

Compatibility with 3300 XL Proximitor Sensors

This probe seamlessly integrates with Bently Nevada’s 3300 XL series of proximitor sensors, providing a comprehensive solution for machine monitoring. -

Durability and Reliability

Designed for high shock and vibration resistance, ensuring long-lasting performance even in demanding industrial applications. -

High Sensitivity

With a sensitivity of 7.87 mV/μm, the probe offers detailed and precise measurements, essential for early detection of faults. -

Compliant with Industry Standards

Meets API 670 and CE standards, ensuring compliance with critical industrial monitoring requirements.

Recent Industry News Headlines

-

“Bently Nevada Announces Enhanced Capabilities for 3300 XL Probes”

New features include improved accuracy and extended temperature ranges. -

“Energy Industry Embraces Proximity Probes for Predictive Maintenance”

Companies adopt 3300 XL probes to minimize downtime and enhance operational efficiency. -

“Bently Nevada’s 3300 Series Probes Revolutionize Turbine Monitoring”

A significant upgrade in vibration monitoring technology for turbines. -

“API 670 Compliance Continues to Drive Demand for Bently Nevada Proximity Probes”

Increasing demand for certified solutions in mission-critical machinery. -

“The Role of Proximity Probes in Preventing Catastrophic Failures in Industrial Plants”

Proximity probes like the 330171-00-26-10-02-00 play a key role in safeguarding plant equipment. -

“Improved Shock Resistance in Bently Nevada’s 3300 Probes Enhances Reliability”

Enhanced durability allows for longer operational life in heavy-duty machinery. -

“Bently Nevada Proximity Probes Ensure Performance and Reliability in Harsh Environments”

Solutions built to withstand extreme conditions in oil and gas applications. -

“New Developments in Machine Monitoring: Bently Nevada Sets the Standard”

Cutting-edge technologies further strengthen Bently Nevada’s position as a market leader.

Frequently Asked Questions (FAQ)

-

What is the typical application for the 330171-00-26-10-02-00 proximity probe?

It is typically used for monitoring the displacement and vibration of rotating machinery, such as turbines, pumps, and compressors. -

Can this probe be used in hazardous environments?

Yes, with proper installation, it can be used in harsh and hazardous environments, including oil & gas and petrochemical plants. -

What is the maximum operating temperature of this probe?

The probe can operate at temperatures up to +177°C. -

How does the reverse mount design benefit installation?

It allows for installation from the rear of the mounting surface, which is helpful in tight or confined spaces. -

What is the length of the cable, and is it flexible for routing?

The probe comes with a 1 meters cable that is flexible enough for installation in larger or complex systems. -

Is the probe suitable for high-vibration applications?

Yes, the probe is designed to handle high shock and vibration levels up to 100 g peak. -

Does this probe work with other Bently Nevada systems?

Yes, it is fully compatible with Bently Nevada’s 3300 XL Proximitor Sensors and other associated hardware. -

What is the sensitivity of the 330171-00-26-10-02-00 probe?

It has a sensitivity of 7.87 mV/μm, offering precise measurements for small changes in shaft displacement. -

How often should the probe be calibrated?

It is recommended to calibrate the probe annually, depending on usage and operational requirements. -

What makes this probe different from the 8 mm version?

The 5 mm version is more compact, making it suitable for smaller shafts and tighter spaces compared to the 8 mm model.

Related Models (Same Series or Function)

| Model Number | Description | Mount Type | Cable Length | Sensitivity | Application |

| 330171-00-08-90-01-05 | 5 mm Reverse Mount, High Temp Variant | Reverse | 8 ft | 7.87 mV/μm | High temperature applications |

| 330171-00-10-15-05 | 5 mm Probe, For General Monitoring | Reverse | 10 ft | 7.87 mV/μm | General vibration monitoring |

| 330171-00-12-10-02-00 | 5 mm Reverse Mount with Extended Cable | Reverse | 12 ft | 7.87 mV/μm | Extended installations |

| 330171-00-08-08-01-01 | 5 mm Proximity Probe with 8 ft Cable | Reverse | 8 ft | 7.87 mV/μm | Standard machinery monitoring |

| 330100-01-06-10-00 | 5 mm Probe with 6 mm Thread | Front Mount | 10 ft | 7.87 mV/μm | General machinery monitoring |

| 330171-00-15-05-02-00 | 5 mm Proximity Probe with 15 ft Cable | Reverse | 15 ft | 7.87 mV/μm | Extended reach installations |

| 330171-00-08-30-01-00 | 5 mm Reverse Mount, 30 ft Cable | Reverse | 30 ft | 7.87 mV/μm | Large industrial systems |

| 330171-00-20-20-10-00 | 5 mm Probe, High Accuracy Variant | Reverse | 20 ft | 7.87 mV/μm | High-precision monitoring |

Popular Bently Nevada Models

| Model Number | Description | Mount Type | Cable Length | Sensitivity | Application |

| 330350-01-08-20-00 | 8 mm Proximity Probe | Reverse | 8 ft | 7.5 mV/μm | Vibration monitoring |

| 330180-01-04-12-00 | 4 mm Proximity Probe | Reverse | 12 ft | 10 mV/μm | Light-duty machinery |

| 330300-01-10-14-00 | 10 mm Proximity Probe | Reverse | 14 ft | 8 mV/μm | Heavy-duty equipment |

| 3300 5 mm Probe Assembly | Standard 5 mm Proximity Probe | Front Mount | 12 ft | 7.87 mV/μm | General machinery monitoring |

| 330180-01-05-10-00 | 5 mm High-Precision Probe | Front Mount | 10 ft | 10 mV/μm | Precision monitoring |

| 330350-01-06-05-00 | 6 mm Proximity Probe | Front Mount | 5 ft | 7.5 mV/μm | Small equipment monitoring |

| 330171-00-08-40-01-00 | 8 mm Proximity Probe with 40 ft Cable | Reverse | 40 ft | 7.5 mV/μm | Long distance applications |

| 330400-01-20-00 | 20 mm Proximity Probe | Reverse | 20 ft | 7.5 mV/μm | Heavy machinery monitoring |

Excellent PLC

Excellent PLC