| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

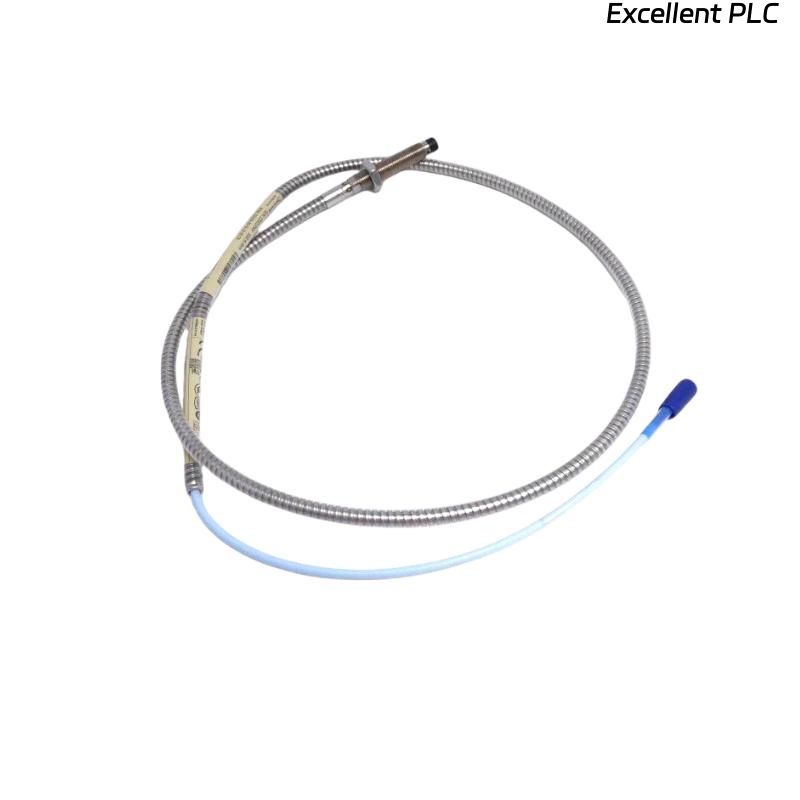

The Bently Nevada 330171-24-57-10-01-05 proximity probe is part of the 3300 series, designed for high-precision vibration and displacement monitoring in industrial environments. This 5mm probe offers unparalleled reliability and accuracy, making it ideal for the condition monitoring of critical rotating machinery, including pumps, motors, turbines, compressors, and fans. By providing real-time measurement of vibration and displacement, the probe enables early detection of mechanical faults such as misalignment, imbalance, and bearing wear.

With its compact design and advanced technology, the 330171-24-57-10-01-05 is particularly suited for use in harsh environments, offering exceptional performance even under extreme conditions. The probe is a key component in predictive maintenance programs, helping to reduce downtime and extend the operational life of machinery.

Technical Specifications

| Parameter | Specification |

|---|---|

| Model | 330171-24-57-10-01-05 |

| Probe Type | 5mm Proximity Probe |

| Total Length | 1.0 meter |

| Weight | 0.323 kg |

| Unthreaded Length | 0.0 inches (0.0 mm) |

| Housing Length | 3.0 inches (76.2 mm) |

| Connector Type | Miniature Coaxial ClickLoc Connector |

| Operating Temperature | -40°C to +120°C |

| Output Signal | 4-20 mA (proportional to vibration or displacement) |

| Power Requirements | -17.5 VDC to -26 VDC, max current 12 mA |

| Linear Range | 2 mm (80 mils) |

| Probe Resistance | 7.45 ± 0.50 Ω (2.0 m length) |

| Target Material | AISI 4140 Steel |

| Mounting | Standard or custom mounting options available |

Applications

The 330171-24-57-10-01-05 proximity probe is widely used in various industrial applications, including:

-

Vibration Monitoring: Provides accurate measurements to detect imbalances, misalignments, and bearing issues in rotating machinery.

-

Condition Monitoring: Essential for real-time tracking of critical machinery like turbines, compressors, and pumps.

-

Predictive Maintenance: Helps in predicting and preventing unexpected downtime by identifying problems before they become serious.

-

Axial Displacement Measurement: Monitors the axial displacement of rotating parts to ensure proper alignment.

-

Machine Health Monitoring: Provides continuous monitoring of machine health, enabling early detection of potential faults.

-

Keyphasor Signal Measurement: Utilized for precise keyphasor signals to monitor rotational speed and alignment.

Advantages

-

High Accuracy: The 330171-24-57-10-01-05 probe delivers highly accurate measurements of vibration and displacement, ensuring the precision needed for critical machinery monitoring.

-

Compact Design: Its compact size makes it ideal for installations in tight spaces where traditional sensors may not fit.

-

Durable and Robust: The probe is built to withstand harsh industrial environments, ensuring long-term performance and reliability.

-

Wide Temperature Range: Operating effectively in temperatures from -40°C to +120°C, making it suitable for diverse environments.

-

Easy Integration: Fully compatible with 3300 XL Proximitor sensors, simplifying the integration process and ensuring seamless operation with existing systems.

-

Low Power Consumption: With low power requirements, it minimizes energy consumption during continuous operation.

-

Electromagnetic Interference Resistance: The probe is designed to function optimally even in environments with significant electromagnetic interference (EMI).

-

Real-time Monitoring: Provides continuous, real-time data, enabling operators to make informed decisions about maintenance and machine health.

-

Cost-Effective: By enabling predictive maintenance, the probe helps reduce the cost of unplanned downtimes and repairs.

-

Improved Safety: Continuous monitoring helps identify potential faults early, improving overall safety and reducing the likelihood of failures leading to hazardous situations.

FAQ

Q1: What type of output signal does this probe provide?

A1: The 330171-24-57-10-01-05 proximity probe provides a 4-20 mA output signal proportional to the measured vibration or displacement.

Q2: What is the operating temperature range of this probe?

A2: The probe operates within a temperature range of -40°C to +120°C, suitable for various industrial environments.

Q3: Can the probe measure axial displacement?

A3: Yes, the 330171-24-57-10-01-05 probe is capable of measuring axial displacement in rotating machinery.

Q4: How is the probe mounted?

A4: The probe can be mounted using standard or custom mounting options, providing flexibility for various installation needs.

Q5: Is this probe suitable for high-vibration environments?

A5: Yes, the probe is designed for high-vibration applications and is commonly used in industries with challenging operational conditions.

Q6: What power supply does the probe require?

A6: The 330171-24-57-10-01-05 probe requires a power supply ranging from -17.5 VDC to -26 VDC and consumes a maximum current of 12 mA.

Q7: Can this probe detect misalignment in rotating equipment?

A7: Yes, the probe is highly effective in detecting misalignments in rotating machinery, such as motors, pumps, and compressors.

Q8: What material is the probe designed to work with?

A8: The 330171-24-57-10-01-05 probe is designed to work with AISI 4140 steel, a commonly used material for industrial machinery.

Q9: Does the probe provide diagnostic capabilities?

A9: Yes, the probe provides real-time data for continuous monitoring, enabling proactive diagnostics and maintenance.

Q10: Is the probe easy to integrate with existing systems?

A10: Yes, the 330171-24-57-10-01-05 probe is fully compatible with 3300 XL Proximitor sensors, ensuring easy integration with existing systems.

Related 3300 Series Models

| Model | Description |

|---|---|

| 330171-24-57-10-01-01 | Enhanced 5mm proximity probe for extended measurement ranges. |

| 330171-24-57-10-01-02 | Compact version of the 5mm proximity probe for tight installations. |

| 330171-24-57-10-01-03 | Standard 5mm proximity probe for general-purpose machine monitoring. |

| 330171-24-57-10-01-04 | Proximity probe designed for high-vibration environments. |

| 330171-24-57-10-01-06 | Proximity probe with integrated diagnostic capabilities. |

| 330171-24-57-10-01-07 | Proximity probe for real-time vibration and displacement monitoring. |

Popular Bently Nevada Models

| Model | Description |

|---|---|

| 330172-00-08-10-01-00 | High-performance module designed for precise data acquisition and process control in industrial applications. |

| 330172-00-08-10-02-05 | Enhanced version with improved signal processing and additional I/O channels for complex systems. |

| 330172-00-09-10-01-00 | Advanced module offering extended environmental tolerance and higher operational stability. |

| 330172-00-09-10-02-05 | High-capacity module with enhanced fault detection and diagnostic capabilities. |

| 330172-00-10-10-01-00 | Ruggedized version designed for reliable performance in harsh industrial conditions. |

| 330172-00-10-10-02-05 | Premium module optimized for high-speed data processing and seamless integration into automation systems. |

Excellent PLC

Excellent PLC