| Company Information | ||||||||

| sales@xmjzjsgs.com | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Overview

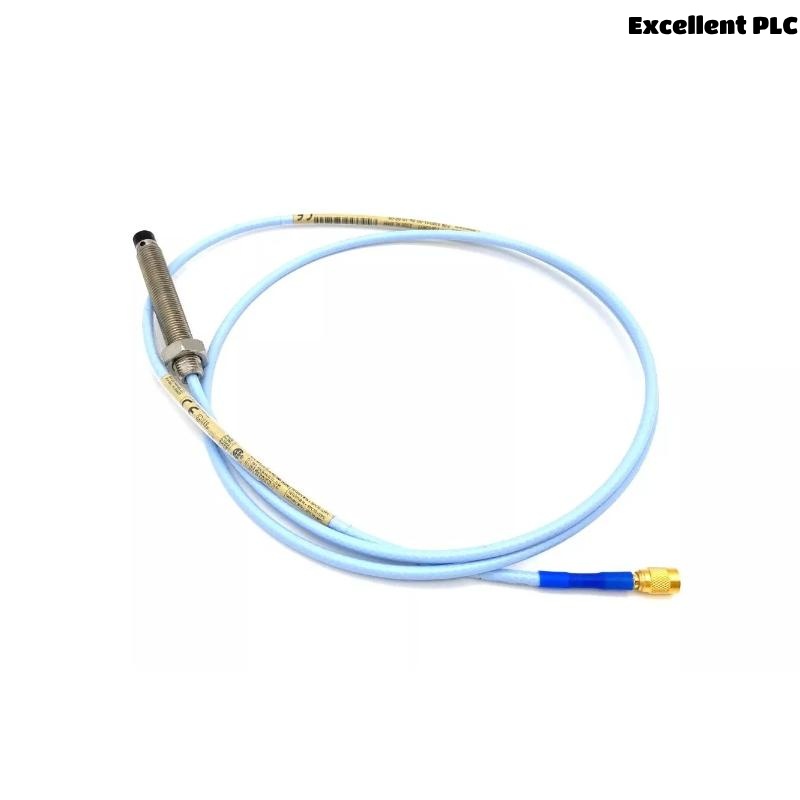

The Bently Nevada 330180-90-10 is part of the 3300 XL 8 mm Proximity Transducer System, designed for precise non-contact measurements of shaft vibration and position. It includes a proximity probe, extension cable, and the 3300 XL Proximitor Sensor. This system meets API 670 standards and ensures robust performance in harsh industrial environments.

Key Applications

-

Shaft vibration monitoring on fluid-film bearing machines

-

Rotating machinery position detection

-

Keyphasor® speed and phase reference signals

-

Turbine and compressor health monitoring

-

Overspeed protection systems (with application note guidance)

Product Advantages

-

High Interchangeability: Fully interchangeable components without field matching or calibration

-

Wide Temperature Support: Probe rated up to 218°C, cable up to 260°C

-

Strong EMC Protection: Enhanced RFI/EMI immunity suitable for fiberglass enclosures

-

Easy Installation: SpringLoc terminals and ClickLoc connectors for secure tool-free wiring

-

Robust Build: TipLoc and CableLoc designs provide enhanced mechanical reliability

-

Flexible Mounting: DIN-rail and panel-mount options with identical footprint to previous models

Technical Specifications

| Parameter | Specification |

|---|---|

| Model Number | 330180-90-10 |

| System Length | 9.0 meters |

| Total System Weight | 0.7 kg |

| Proximitor Sensor Weight | 0.246 kg |

| Frequency Response | 0 to 10 kHz (+0, -3 dB) |

| Linear Range | 2 mm (80 mils) |

| Recommended Gap Setting | 1.27 mm (50 mils) |

| Output Sensitivity | 7.87 V/mm ± 6.5% |

| Deviation from Straight Line | ±0.038 mm (±1.5 mils) |

| Temperature Range – Probe | -52°C to +177°C (Standard), up to +218°C (ETR) |

| Temperature Range – Cable | -52°C to +260°C |

| Temperature Range – Sensor | Operating: -52°C to +100°C |

| Minimum Shaft Diameter | 50.8 mm (recommended ≥76.2 mm) |

| Minimum Target Size | 15.2 mm diameter |

| Connector Torque | 0.565 N·m (5 in·lbf) max |

| Cable Bend Radius | 25.4 mm (1 in) minimum |

| Output Resistance | 50 Ω |

| Probe Tip Material | PPS (Polyphenylene Sulfide) |

| Probe Case Material | Stainless Steel (AISI 303 or 304) |

| Cable Type | 75Ω triaxial with FEP or PFA insulation |

Frequently Asked Questions (FAQ)

Q1: What is the purpose of the 330180-90-10 sensor?

A1: It measures shaft vibration and position in rotating equipment.

Q2: Is it compatible with previous 3300 series systems?

A2: Yes, it’s backward compatible with 3300 5 mm and 8 mm components.

Q3: Can this sensor be used in hazardous environments?

A3: Yes, it has ATEX, CSA, and IECEx approvals for hazardous area use.

Q4: What is the advantage of using ClickLoc connectors?

A4: They provide secure, tool-free connections with corrosion-resistant gold plating.

Q5: What is the effect of long field wiring on signal quality?

A5: It can cause signal roll-off at high frequencies; keep within 305 meters.

Q6: Can I use this sensor for overspeed protection?

A6: Yes, but follow Bently Nevada’s specific application notes for proper setup.

Q7: Does the sensor require calibration?

A7: No, all components are factory calibrated and interchangeable.

Q8: What materials can it be calibrated for besides AISI 4140?

A8: It can be specially calibrated for other conductive materials upon request.

Q9: What kind of installation options are available?

A9: Supports both DIN-rail and traditional panel-mount installations.

Q10: What is the expected service life of this sensor system?

A10: With proper installation, it offers long-term durability even in harsh conditions.

Related Models in the Same Series

| Model Number | System Length | Cable Type | Application Range |

|---|---|---|---|

| 330180-50-10 | 5.0 m | Standard | General industrial use |

| 330180-11-10 | 1.0 m | DIN Mount | Compact enclosures |

| 330180-91-05 | 9.0 m | DIN Mount | Extended installations |

| 330180-10-05 | 1.0 m | Panel Mount | Control panels |

| 330180-51-00 | 5.0 m | DIN Mount | High-density wiring setups |

| 330180-12-00 | 1.0 m | No Mount Hardware | OEM integrations |

Popular Bently Nevada Models

| Model Number | Description | Application | System Length | Weight |

|---|---|---|---|---|

| 330104-00-06-10-11-00 | 8 mm Proximity Probe | Vibration monitoring | 9.0 m | 0.246 kg |

| 330104-00-06-50-01-00 | 8 mm Proximity Probe | Shaft position detection | 5.0 m | 0.246 kg |

| 3500/42M-01-00 | Proximitor Seismic Monitor | Machinery protection | N/A | 0.45 kg |

| 3500/22M | Transient Data Interface Module | Vibration data acquisition | N/A | 0.7 kg |

| 3500/15 | Power Supply Module | System power regulation | N/A | 0.8 kg |

| 3300 XL NSv | Narrow Side-View Proximity Probe System | Small clearance machine spaces | 5.0 m | 0.23 kg |

Excellent PLC

Excellent PLC