| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Description

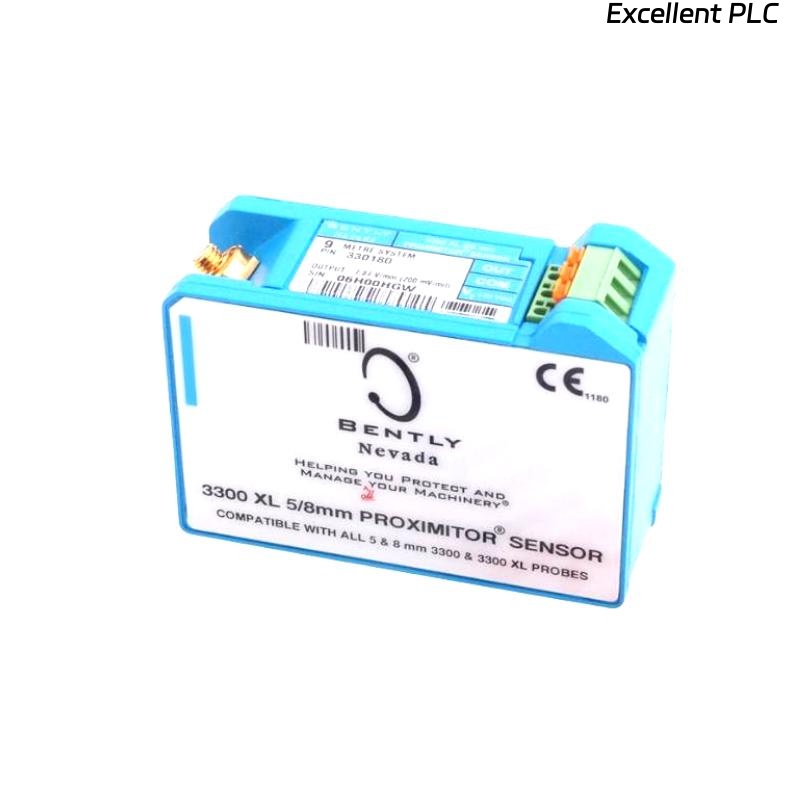

The Bently Nevada 330180-X1-05 145004-81 3300 XL Proximitor Sensor is part of the 3300 XL 8 mm Proximity Transducer System, which includes a probe, extension cable, and the Proximitor sensor. It measures the distance between the probe tip and a conductive surface, providing both static (position) and dynamic (vibration) measurements. Designed for use in fluid-film bearing machines, it supports API 670 compliance, high reliability, and full interchangeability among probes, extension cables, and sensors.

Technical Specifications

| Parameter | Specification |

|---|---|

| System Type | 3300 XL 8 mm Proximity Transducer |

| Operating Voltage | -17.5 Vdc to -26 Vdc |

| Output Resistance | 50 Ω |

| Linear Range | 2 mm (80 mils) |

| Recommended Gap | -9 Vdc (~1.27 mm / 50 mils) |

| ISF | 7.87 V/mm (200 mV/mil) ±5% (5 m or 1 m), ±6.5% (9 m) |

| Frequency Response | 0–10 kHz (+0, -3 dB) |

| Probe Tip Material | Polyphenylene sulfide (PPS) |

| Probe Case Material | AISI 303/304 stainless steel |

| Connector Type | Gold-plated ClickLoc |

| Temperature Range (Probe) | -52°C to +177°C (standard), up to +218°C (ETR) |

| Temperature Range (Sensor) | -52°C to +100°C operating |

| Dimensions (Sensor) | 81.3 × 35.1 × 63.5 mm |

| Weight (Sensor) | 0.246 kg |

Applications

-

Vibration and position measurement in turbines, compressors, pumps, and other rotating machinery

-

Keyphasor reference and speed measurement

-

Machinery condition monitoring in power generation, petrochemical, and industrial sectors

-

Use in hazardous environments with CSA, ATEX, and IECEx certifications

Advantages

-

API 670 Compliant – Meets industry standards for linear range, accuracy, and stability

-

High Immunity to RFI/EMI – Reliable operation without costly shielding

-

SpringLoc Terminals – Tool-free wiring connections for faster installation

-

Full Interchangeability – No calibration required when swapping system components

-

Enhanced Mechanical Robustness – TipLoc and CableLoc technology improves durability

-

Extended Temperature Options – Suitable for extreme industrial conditions

FAQ

Q1: What is the primary function of the 330180-X1-05 sensor?

A1: It measures static and dynamic shaft position/vibration in rotating equipment.

Q2: Is the sensor API 670 compliant?

A2: Yes, the system meets API 670 standards for configuration, range, and accuracy.

Q3: Can it be used in hazardous areas?

A3: Yes, with CSA, ATEX, and IECEx approvals for various hazardous zones.

Q4: Does it require special tools for installation?

A4: No, SpringLoc terminals and ClickLoc connectors allow tool-free installation.

Q5: What is the linear range of the system?

A5: 2 mm (80 mils), starting at approximately 0.25 mm from the target.

Q6: Can components from older 3300 series systems be used?

A6: Yes, it is backward compatible with non-XL 3300 5 mm and 8 mm components.

Q7: What is the recommended gap for radial vibration measurements?

A7: Approximately 1.27 mm (50 mils), corresponding to -9 Vdc.

Q8: How is the probe cable protected from oil leakage?

A8: An optional FluidLoc cable prevents oil ingress through the cable interior.

Q9: What is the weight of the Proximitor sensor?

A9: 0.246 kg.

Q10: What temperature range can the ETR version handle?

A10: Up to +218°C for the probe tip and +260°C for the cable.

Related Models (Same Series)

| Model | Description | Length Option | Temperature Rating |

|---|---|---|---|

| 330180-10-00 | Proximitor Sensor, 1 m, Panel Mount | 1 m | Standard |

| 330180-11-05 | Proximitor Sensor, 1 m, DIN Mount, ATEX | 1 m | Standard |

| 330180-50-00 | Proximitor Sensor, 5 m, Panel Mount | 5 m | Standard |

| 330180-51-05 | Proximitor Sensor, 5 m, DIN Mount, ATEX | 5 m | Standard |

| 330180-90-00 | Proximitor Sensor, 9 m, Panel Mount | 9 m | Standard |

| 330180-91-05 | Proximitor Sensor, 9 m, DIN Mount, ATEX | 9 m | Standard |

Popular Models from Bently Nevada

| Model | Description | Application | Key Feature |

|---|---|---|---|

| 330104-00-06-10-11-00 | 3300 XL 8 mm Proximity Probe | Turbine Vibration | High durability |

| 330105-02-12-05-02-00 | 8 mm Reverse Mount Probe | Limited Space | Reverse installation |

| 3500/42M-01-00 | Proximitor Seismic Monitor | Seismic & Vibration Monitoring | API 670 compliant |

| 3500/22M | Transient Data Interface | Machinery Diagnostics | High-speed data |

| 3500/93 | System Rack Interface Module | Rack Integration | High-speed comms |

| 330130-040-00-00 | 3300 XL Extension Cable, 4 m | Probe Connection | ClickLoc connector |

Excellent PLC

Excellent PLC