| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

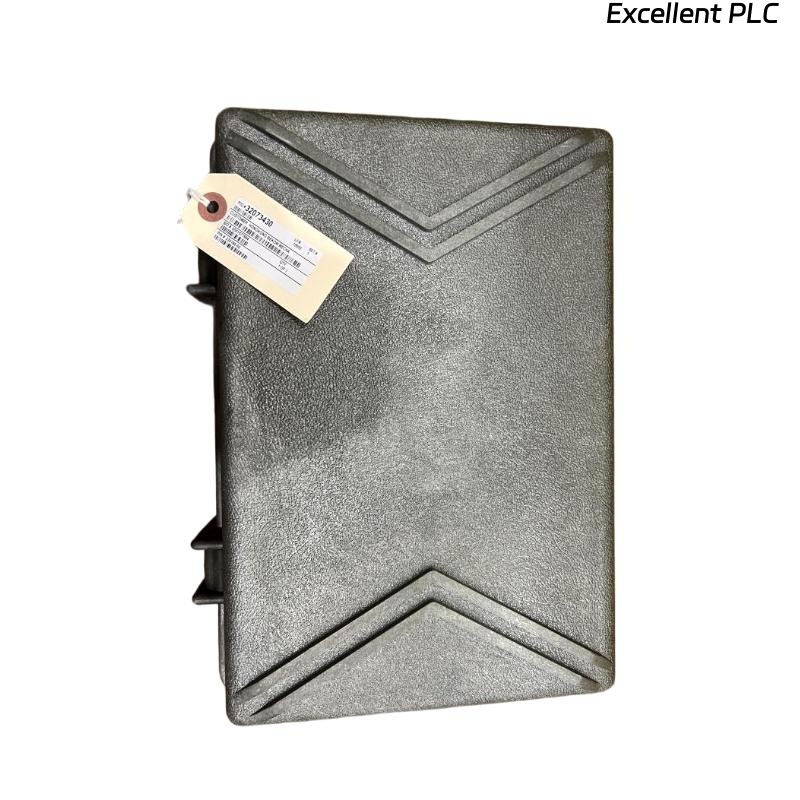

The Bently Nevada 330186-02 3300 XL Shaft Micrometer is a precision measurement device designed for accurate shaft and rotor alignment verification in industrial machinery. As part of the 3300 XL monitoring system, it provides highly reliable data for assessing shaft position, clearances, and vibration patterns. This instrument is widely used in power generation, petrochemical, and manufacturing facilities where precise shaft measurement is critical to ensure safe and efficient operation.

The device features a 0-25 mm scale, enabling fine-resolution measurements of shaft displacement. Its rugged construction and high-precision scale allow technicians to conduct quick and reliable checks on rotating equipment without compromising accuracy. Designed to complement the 3300 XL system, the micrometer supports predictive maintenance and helps prevent costly downtime caused by misalignment or excessive shaft movement.

With a weight of 2.8 kg, the unit is robust yet portable enough for field inspection, offering a balance between durability and operational convenience. The 330186-02 micrometer ensures consistency in measurement under varying environmental conditions, making it a reliable tool for machinery monitoring teams.

Product Parameters

| Parameter | Description |

|---|---|

| Product Model | Bently Nevada 330186-02 |

| Series | 3300 XL Monitoring System |

| Product Type | Shaft Micrometer |

| Scale Units | 0-25 mm |

| Measurement Type | Shaft displacement and clearance |

| Resolution | 0.01 mm typical |

| Accuracy | ±0.02 mm |

| Material | Stainless steel body with precision scale |

| Operating Temperature | -20°C to +60°C |

| Weight | 2.8 kg |

| Mounting Type | Hand-held / Field application |

| Environmental Protection | Resistant to oil, dust, and moisture |

| Compatibility | Works with 3300 XL monitoring system for calibration and verification |

| Calibration | Factory-calibrated; re-calibration supported |

| Power Requirement | None (manual operation) |

| Typical Use | Machinery alignment, rotor shaft clearance, and displacement measurement |

Product Applications

The 330186-02 Shaft Micrometer is used in industrial environments requiring precise shaft measurement and machinery condition verification. Common applications include:

-

Steam and Gas Turbines: Verifies rotor alignment and shaft clearances to prevent mechanical failures.

-

Compressors: Measures shaft displacement and vibration for condition monitoring and maintenance planning.

-

Generators: Checks shaft alignment and rotor movement to reduce vibration and mechanical stress.

-

Pumps and Fans: Monitors shaft positioning to prevent misalignment-related wear and failure.

-

Gearboxes: Assists in verifying proper alignment and detecting dynamic shaft displacement.

-

Predictive Maintenance Programs: Supports accurate measurement for machinery health diagnostics and early warning of potential faults.

Product Advantages

The Bently Nevada 330186-02 Shaft Micrometer offers several advantages for industrial use:

-

High Measurement Precision: Provides fine-resolution readings with ±0.02 mm accuracy.

-

Durable Construction: Stainless steel body ensures long-term reliability in industrial environments.

-

Portable Design: Lightweight enough for field use, yet robust for repeated application.

-

Direct Measurement: Allows technicians to verify shaft displacement and clearances without complex equipment.

-

Compatibility with 3300 XL Systems: Supports alignment verification and calibration for 3300 XL probes and modules.

-

Environmental Resistance: Sealed against oil, dust, and moisture for reliable field operation.

-

Predictive Maintenance Support: Enables early detection of misalignment or rotor anomalies.

-

Easy to Use: Hand-held design and clear scale simplify measurement tasks.

-

Consistent Accuracy: Maintains precision over repeated use and under varying field conditions.

-

Supports Safety and Reliability: Reduces risk of machinery failure by providing accurate alignment data.

FAQ

-

What is the measurement range of the 330186-02 micrometer?

The scale range is 0-25 mm, suitable for standard shaft displacement measurements. -

What is the resolution and accuracy of this micrometer?

Resolution is 0.01 mm, with an accuracy of ±0.02 mm. -

Can this device be used in high-temperature environments?

It is designed to operate reliably between -20°C and +60°C. -

Is the micrometer compatible with the 3300 XL system?

Yes, it can be used to calibrate and verify shaft positions in conjunction with 3300 XL modules. -

Does the micrometer require power to operate?

No, it is manually operated and does not require any power source. -

Can it measure axial as well as radial shaft displacement?

Yes, it can measure both axial and radial movement depending on mounting and application. -

Is the micrometer resistant to industrial contaminants?

Yes, it is resistant to oil, dust, and moisture. -

Can the device be used for both field and workshop inspections?

Yes, its portable design makes it suitable for both field and controlled environments. -

Does it need periodic calibration?

The micrometer is factory-calibrated, but periodic re-calibration is supported to maintain accuracy. -

How is the micrometer typically mounted or used?

It is hand-held for direct measurement on shafts, typically positioned against the rotor or shaft surface to assess displacement.

Related Models (Same Series or Similar Types)

| Model | Description |

|---|---|

| 330186-01 | 3300 XL Shaft Micrometer, 0-10 mm scale |

| 330186-03 | 3300 XL Shaft Micrometer, 0-50 mm scale |

| 330186-04 | 3300 XL Shaft Micrometer, 0-75 mm scale |

| 330187-01 | 3300 XL Shaft Alignment Gauge, 0-25 mm scale |

| 330188-01 | 3300 XL Proximity Probe Verification Tool |

| 330189-01 | 3300 XL Rotor Measurement Kit |

Popular Models from the Same Brand

| Model | Product Type | Description |

|---|---|---|

| 330103-00-05-10-02-00 | Proximity Probe | 8mm standard proximity probe for 3300 XL systems |

| 330130-040-00 | Extension Cable | Cable extension for proximity probe systems |

| 3300 XL 11mm | Proximity Transducer System | Extended-range proximity measurement system |

| 190501-09-99 | Velomitor CT Velocity Transducer | High-precision velocity transducer for vibration monitoring |

| 3500/22M | Transient Data Interface | Data interface module for dynamic monitoring in 3500 systems |

| 330500-01-00 | Accelerometer | High-sensitivity accelerometer for vibration and condition monitoring |

Excellent PLC

Excellent PLC