| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

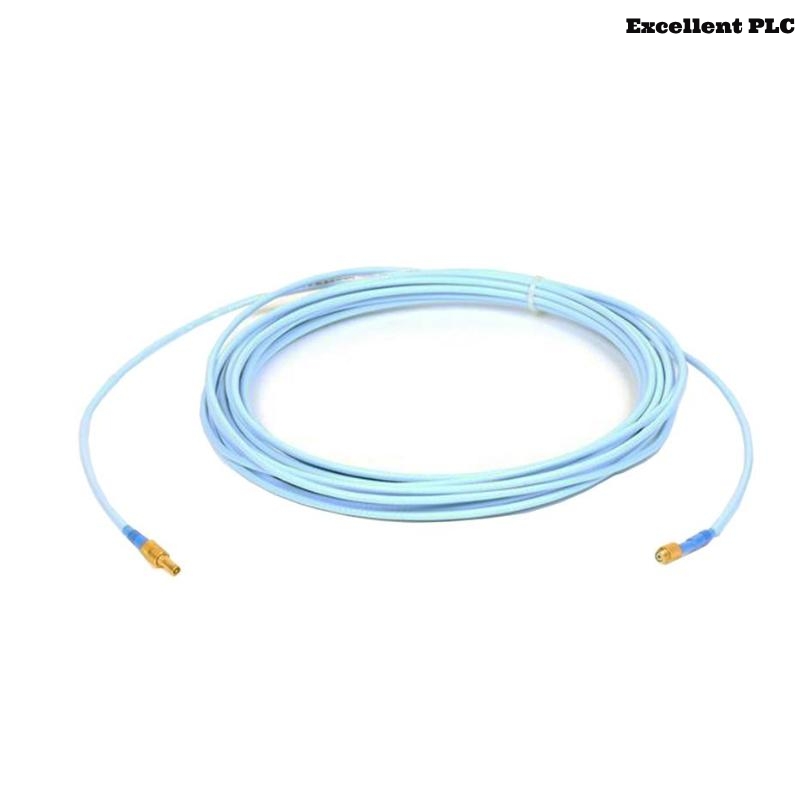

The Bently Nevada 330190-045-00-00 is an essential component of the 3300 XL ETR (Extended Temperature Range) Proximity Transducer System, manufactured by the globally recognized brand Bently Nevada, a GE company. This specific part number corresponds to a 4.5 meters extension cable, designed to connect proximity probes to the corresponding Proximitor® sensors.

This cable is built for mission-critical machinery monitoring under extreme environmental conditions, such as those found in refineries, power plants, and offshore platforms. The 330190 series is known for its robust construction, high temperature resistance, and reliable signal transmission, ensuring long-term performance even under continuous exposure to heat, vibration, and electromagnetic interference.

When integrated into the 3300 XL ETR system, the cable forms a reliable communication channel between the probe and sensor, making it indispensable for precise vibration measurement, shaft position monitoring, and early fault detection in rotating machinery.

Product Specifications

| Parameter | Description |

| Model Number | 330190-045-00-00 |

| Product Type | Extension Cable |

| Series | 3300 XL ETR (Extended Temperature Range) |

| Total Length | 4.5 meters |

| Connector Type | MIL-C-5015 Circular Connectors |

| Operating Temperature | -55°C to +200°C (-67°F to +392°F) |

| Outer Cable Material | PTFE Jacket with overall braided shielding |

| Cable Diameter | ~6.2 mm (0.24 inches) |

| Minimum Bend Radius | 2.5 inches (63.5 mm) |

| Weight | 0.153 kg |

| Impedance Matching | Optimized for use with Bently Nevada Proximitor® sensors |

| Shielding Type | Full-length EMI/RFI braided shield |

| Compliance | API 670 compliant, RoHS, CE Certified |

| Environmental Protection | Resistant to oil, solvents, and mechanical abrasion |

| Application Compatibility | Proximity Transducer Systems for rotating equipment |

Product Applications

The 330190-045-00-00 cable is purpose-built for dynamic and static measurement systems in industrial environments. Typical applications include:

-

Steam and Gas Turbines

-

Axial and Radial Compressors

-

Centrifugal and Reciprocating Pumps

-

Large Electric Motors and Generators

-

Gearboxes and Couplings

-

Critical Rotating Machinery in API 670-compliant systems

These applications span across key sectors:

-

Oil & Gas (Refining, Midstream, Upstream)

-

Petrochemical Processing

-

Thermal and Nuclear Power Generation

-

Marine Propulsion Systems

-

Heavy Industrial Manufacturing

-

Offshore Platforms and FPSOs

Product Advantages

-

Extended Temperature Range Support: Operating from -55°C to +200°C, making it suitable for high-heat zones like turbines and refineries.

-

Mechanical Durability: Designed with rugged PTFE outer jackets to resist abrasion and harsh chemicals.

-

Electromagnetic Immunity: The full-length braided shield minimizes noise interference for accurate signal transmission.

-

High Flexibility in Layout: Available in multiple lengths; the 45-foot version suits systems requiring remote sensing installations.

-

Plug-and-Play Integration: Factory-terminated connectors ensure fast installation with no field soldering or modification required.

-

Standard Compliance: Meets global standards including API 670 and CE regulations, ensuring compatibility with safety and monitoring protocols.

-

Low Maintenance: Once installed, the cable typically requires no active servicing.

-

Proven Field Reliability: Trusted in some of the most demanding industrial environments globally.

Latest Industry Headlines Related to the Product/Brand

-

“GE’s Bently Nevada Launches New Line of High-Temp Monitoring Solutions”

-

“Condition Monitoring Technologies Reshape Predictive Maintenance Strategies”

-

“API 670 Standards Updated: What it Means for Your Monitoring Systems”

-

“Extended Temperature ETR Series Now Integrated into LNG and Offshore Assets”

-

“GE Digital and Bently Nevada Push Toward Real-Time Machinery Diagnostics”

-

“Global Power Utilities Shift to Non-Intrusive Monitoring with 3300 XL Series”

-

“Vibration Monitoring Prevents Catastrophic Failure in Gas Turbine Case Study”

-

“Bently Nevada Enhances Support for Remote Plant Installations with XL ETR Cabling”

Frequently Asked Questions (FAQ)

1. What is the primary function of the 330190-045-00-00 extension cable?

It connects the proximity probe to the Proximitor® sensor, ensuring reliable signal transmission over 45 feet.

2. Is this cable interchangeable with non-ETR 3300 series cables?

No. This cable is designed specifically for use in ETR (Extended Temperature Range) environments and may not be compatible with standard 3300 systems.

3. Can the cable withstand extreme outdoor conditions?

Yes. It’s built for operation in both high-temperature and chemically harsh environments.

4. What is the maximum temperature this cable can operate at?

Up to +200°C, making it suitable for turbine decks and other high-heat applications.

5. Can I cut or re-terminate this cable on-site?

No. The connectors are factory-installed. Field modification is not recommended as it can compromise performance.

6. How often does the cable need to be inspected or replaced?

Under normal conditions, it has a long operational life and needs minimal maintenance, but annual inspection is advised.

7. Does the cable support data communication?

It transmits analog signals used in proximity and vibration monitoring systems.

8. Is shielding important in this cable?

Yes. The braided shield prevents electromagnetic interference, preserving signal clarity.

9. How is it mounted or routed in complex installations?

It is flexible enough for use in conduits or cable trays and supports multiple routing paths.

10. Where is this cable manufactured?

This cable is manufactured in the USA.

Recommended Models – Same Series or Related

| Model Number | Description | Cable Length | System Compatibility |

| 330190-010-00-00 | 3300 XL ETR Extension Cable | 10 feet | 3300 XL ETR |

| 330190-015-00-00 | 3300 XL ETR Extension Cable | 15 feet | 3300 XL ETR |

| 330190-025-00-00 | 3300 XL ETR Extension Cable | 25 feet | 3300 XL ETR |

| 330190-050-00-00 | 3300 XL ETR Extension Cable | 50 feet | 3300 XL ETR |

| 330130-040-00-00 | XL Extension Cable | 4 meters | 3300 XL |

| 330180-91-05 | Standard Extension Cable (non-ETR) | 5 meters | 3300 Series |

| 330105-02-12-10-02-00 | 3300 XL Proximitor Sensor | N/A | Works with XL Probes & Cables |

| 330500-02-00 | High-temp Cable Assembly | N/A | 3300 XL ETR and special systems |

Popular Bently Nevada Models – Same Brand

| Model Number | Description | Function | Used In |

| 3500/22M | Transient Data Interface Module | Data Interface | 3500 Series Systems |

| 3500/42M | Proximitor/Seismic Monitor Module | Vibration Monitoring | Critical Rotating Equipment |

| 3500/25 | Keyphasor Module | Speed & Phase Monitoring | Turbine/Compressor Skids |

| 3500/15 | AC/DC Power Supply Module | Power Delivery | Entire 3500 Rack Systems |

| 330104-00-05-10-02-00 | Proximity Probe | Displacement/Vibration | Pumps, Turbines |

| 330130-080-00-00 | XL Extension Cable | Signal Extension | 3300 XL System |

| 330180-90-00 | Proximitor Extension Cable | Extended Connection | Large Machine Monitoring |

| 165809-01 | Velocity Sensor | Seismic Monitoring | Compressors, Pumps |

Excellent PLC

Excellent PLC