| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Overview

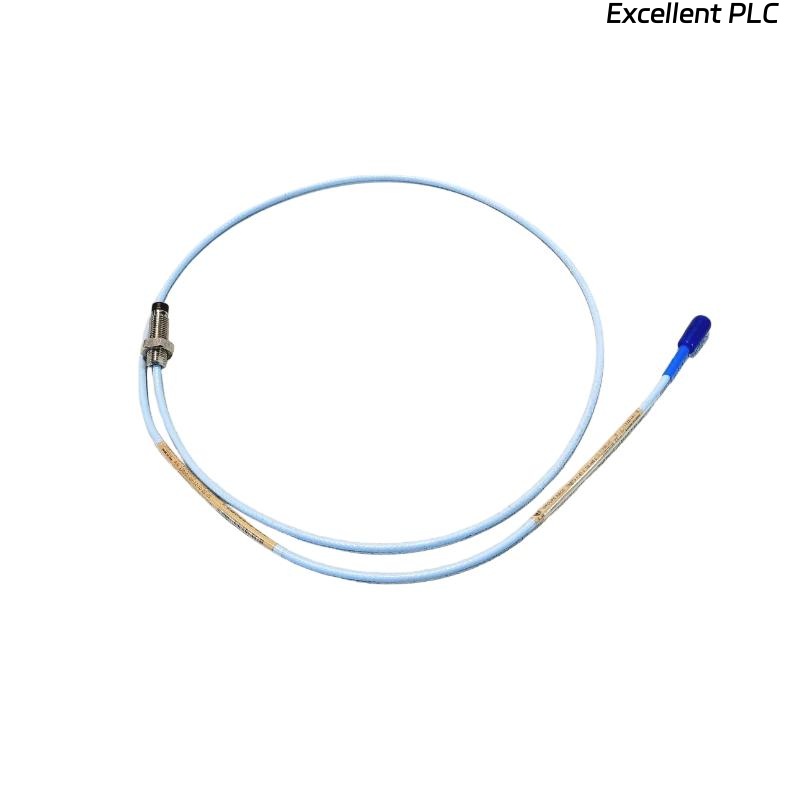

The Bently Nevada 330195-02-12-05-CN 3300 XL 8 mm ETR Reverse Mount Probe is a high-performance vibration probe designed for advanced monitoring applications in industrial environments. Part of the renowned 3300 XL series, this reverse mount probe offers exceptional reliability and precision, making it ideal for monitoring critical machinery in industries such as power generation, oil and gas, and manufacturing.

Designed with a robust construction, the 330195-02-12-05-CN is engineered to provide accurate vibration measurements, even in the most demanding environments. Its reverse mount design allows for easier installation in tight spaces or specialized equipment, ensuring versatility in its application. The probe is compatible with Bently Nevada’s 3300 XL Transducer System, enabling users to track machinery health and performance, and detect potential failures before they occur.

This probe features a high-quality 8 mm shaft, which ensures precise vibration measurements for a variety of industrial monitoring systems. It helps to prevent costly unplanned downtime by identifying faults such as imbalance, misalignment, and bearing wear, and alerts maintenance teams to potential issues before they lead to failure.

Technical Specifications

| Parameter | Specification |

|---|---|

| Model | 330195-02-12-05-CN |

| Total Length | 0.5 meter |

| Weight | 0.162 kg |

| Shaft Diameter | 8 mm |

| Probe Type | Reverse Mount |

| Operating Temperature | -40°C to 85°C |

| Output | 4-20 mA (Analog) |

| Mounting | Reverse Mount |

| Frequency Range | 1 Hz to 10 kHz |

| Cable Length | Customizable up to 30 meters |

| Compliance | CE, UL |

Product Applications

The Bently Nevada 330195-02-12-05-CN 3300 XL 8 mm ETR Reverse Mount Probe is specifically designed for a wide range of industrial applications, including:

-

Power Generation: Used for monitoring vibration in turbines, generators, and other rotating machinery, providing early detection of faults that could lead to unexpected shutdowns.

-

Oil and Gas: Essential in offshore platforms and refineries, where vibration analysis is critical to ensuring the safe and efficient operation of pumps, compressors, and motors.

-

Manufacturing: Commonly used in manufacturing plants to monitor the health of critical equipment such as motors, conveyor belts, and gearboxes.

-

Mining: Deployed in mining operations to track the condition of crushers, conveyors, and mills, helping to reduce unplanned downtime and maintenance costs.

-

Chemical and Pharmaceutical Industries: Helps monitor pumps, mixers, and other sensitive equipment that must operate within specific parameters to ensure product quality and safety.

The 3300 XL 8 mm ETR Reverse Mount Probe provides the reliable, real-time data needed to keep industrial machinery running efficiently and effectively, preventing unnecessary downtime and costly repairs.

Product Advantages

-

Precise Vibration Measurements: The 8 mm shaft ensures high accuracy and reliability in capturing vibration data, essential for early fault detection and predictive maintenance.

-

Reverse Mount Design: The reverse mount feature makes installation easier in tight spaces or specialized equipment, providing flexibility for various industrial environments.

-

Wide Operating Temperature Range: With an operating range from -40°C to 85°C, this probe is suitable for both hot and cold environments, ensuring reliable performance in extreme conditions.

-

Versatile Application: Compatible with a wide variety of industrial equipment, from turbines and generators to motors and pumps, making it a versatile tool for any monitoring system.

-

Long Cable Options: Customizable cable lengths of up to 30 meters provide installation flexibility and make it easy to use in large or complex systems.

-

Durable and Reliable: The probe is built to last with high-quality materials and robust construction, ensuring long-term use even in harsh industrial settings.

-

Advanced Monitoring Capabilities: When used with the 3300 XL Transducer System, it offers advanced monitoring features like real-time data collection, fault detection, and analysis, allowing for proactive maintenance.

FAQ

1. What is the shaft diameter of the Bently Nevada 330195-02-12-05-CN Probe?

The probe features an 8 mm shaft diameter, providing precise and reliable vibration measurements in industrial applications.

2. How long is the cable on the Bently Nevada 330195-02-12-05-CN Probe?

The cable length is customizable, with a maximum length of up to 30 meters, offering flexibility for a wide range of installations.

3. What is the operating temperature range of the Bently Nevada 330195-02-12-05-CN?

The probe can operate in temperatures ranging from -40°C to 85°C, making it suitable for both hot and cold environments.

4. What type of output does the Bently Nevada 330195-02-12-05-CN Probe provide?

The probe provides a 4-20 mA analog output, which is standard for vibration monitoring systems.

5. What is the frequency range of the Bently Nevada 330195-02-12-05-CN Probe?

The probe offers a frequency range from 1 Hz to 10 kHz, ensuring it can accurately capture a wide range of vibration frequencies.

6. Can the Bently Nevada 330195-02-12-05-CN be used for real-time vibration monitoring?

Yes, the 3300 XL 8 mm ETR Reverse Mount Probe is designed for real-time vibration monitoring, providing critical data to detect faults early.

7. What industries use the Bently Nevada 330195-02-12-05-CN Probe?

This probe is commonly used in power generation, oil and gas, manufacturing, mining, and chemical and pharmaceutical industries.

8. Is the Bently Nevada 330195-02-12-05-CN Probe compatible with other Bently Nevada systems?

Yes, it is fully compatible with Bently Nevada’s 3300 XL Transducer System for comprehensive vibration monitoring.

9. How does the reverse mount design benefit installations?

The reverse mount design allows for easier installation in tight spaces, offering flexibility and reducing installation time.

10. What protection features does the Bently Nevada 330195-02-12-05-CN Probe have?

The probe features durable construction with protection against environmental factors such as high temperatures, vibration, and mechanical stress.

Model Recommendations

| Model | Description |

|---|---|

| 330195-02-12-05-01 | Similar model with different mounting options |

| 330195-02-12-07-CN | Enhanced version with extended temperature range |

| 330195-02-12-10-CN | Model with larger shaft diameter for heavy-duty applications |

| 330195-02-12-05-03 | Probe designed for high-speed machinery monitoring |

| 330195-02-12-15-CN | Probe with built-in diagnostics for advanced monitoring |

| 330195-02-12-20-CN | Version with wireless transmission capabilities |

Popular Bently Nevada Models

| Model | Description |

|---|---|

| 330130-050-00 | High-precision 3300 XL 5 mm vibration probe |

| 330103-051-01 | Advanced vibration sensor with integrated diagnostics |

| 330106-02-12-05 | Model with extended cable length for remote monitoring |

| 330106-01-12-01 | Compact vibration probe with high-frequency response |

| 330104-01-12-10 | Vibration sensor designed for harsh environments |

| 330104-02-10-01 | Heavy-duty vibration probe for industrial machinery |

Excellent PLC

Excellent PLC