| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

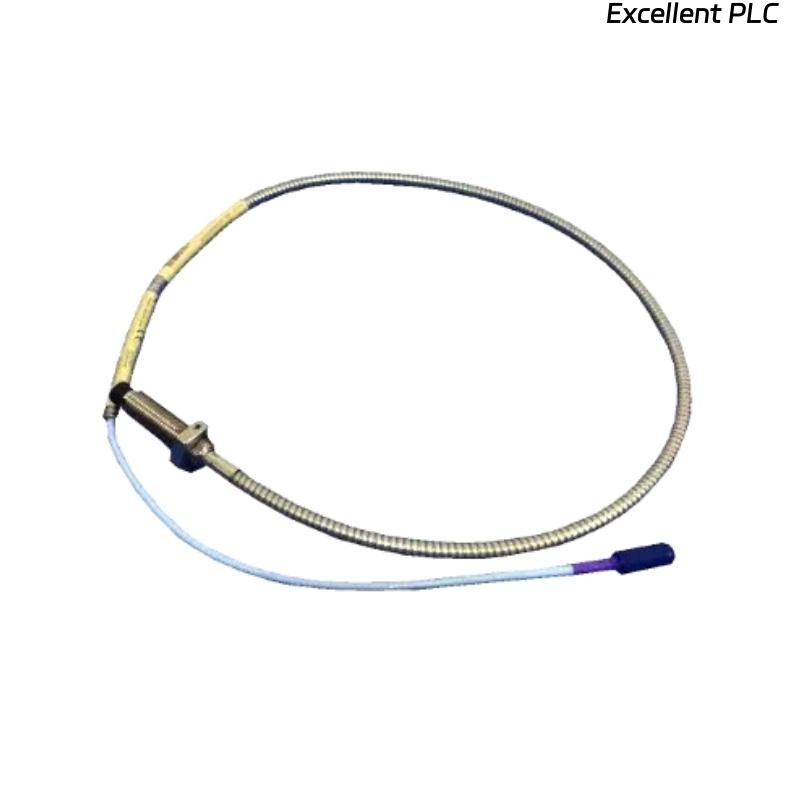

The Bently Nevada 330196-05-30-50-05 3300 XL 8 mm ETR Reverse Mount Probe is a high-performance proximity probe engineered for accurate shaft vibration and displacement measurement in critical rotating machinery. Designed for reverse-mount installation, it provides an ideal solution when space constraints or mechanical layouts prevent traditional forward-mounting. Its robust construction and proven compatibility with the 3300 XL monitoring platform make it a trusted component for machinery protection and predictive maintenance programs. Built with corrosion-resistant materials and precision manufacturing, it maintains measurement stability even in demanding industrial environments.

Product Specifications

| Parameter | Description |

|---|---|

| Model Number | 330196-05-30-50-05 |

| Series | 3300 XL 8 mm ETR Reverse Mount Probes |

| Measurement Range | 2 mm (80 mils) non-contact displacement |

| Sensitivity | 7.87 mV/µm typical |

| Linearity | ±1 % over calibrated range |

| Operating Temperature | −40 °C to +125 °C |

| Humidity | 0–95 % non-condensing |

| Vibration Tolerance | Up to 20 g, 10–2000 Hz |

| Insulation Resistance | >100 MΩ at 500 V DC |

| Dielectric Strength | 2.5 kV AC for 1 minute |

| Probe Tip Diameter | 8 mm |

| Total Length | 5.0 meters |

| Weight | 1.615 kg |

| Mounting Style | Reverse-mount threaded installation |

| Output Signal | Differential voltage, 3300 XL compatible |

| Housing Material | Stainless steel with corrosion-resistant finish |

Applications

-

Steam and Gas Turbines: Delivers continuous shaft vibration monitoring for early detection of imbalance and misalignment.

-

Compressors and Pumps: Safeguards equipment by measuring shaft displacement to prevent bearing damage or rotor instability.

-

Petrochemical Processing: Operates reliably in environments with high humidity and chemical exposure.

-

Power Generation Units: Integrates directly with 3300 XL monitoring systems for predictive maintenance and machine protection.

-

Industrial Motors and Fans: Provides accurate vibration measurements for any rotating equipment requiring high-precision condition monitoring.

Advantages

-

Reverse-Mount Design: Enables installation in confined or otherwise inaccessible areas where standard forward mounting is impractical.

-

Exceptional Accuracy: Maintains precise displacement and vibration measurement for reliable machinery protection.

-

Rugged Environmental Performance: Withstands extreme temperatures, heavy vibration, and electrical noise without degradation.

-

Durable Construction: Stainless-steel housing and corrosion-resistant finish ensure long service life under harsh conditions.

-

Seamless System Integration: Fully compatible with Bently Nevada 3300 XL hardware, simplifying system upgrades and replacements.

Frequently Asked Questions (FAQ)

-

Can this probe be installed in any orientation?

Yes, the reverse-mount threaded design allows secure installation in horizontal, vertical, or angled positions without affecting accuracy. -

What is the supported measurement range and sensitivity?

It measures up to 2 mm of non-contact shaft displacement with a typical sensitivity of 7.87 mV/µm, providing precise vibration detection. -

Is the probe compatible with all Bently Nevada 3300 XL monitors?

Yes, it is specifically engineered to integrate seamlessly with all 3300 XL monitoring modules for vibration and shaft-position applications. -

How is alignment maintained during reverse mounting?

A threaded rear-mount design with locking hardware ensures proper gap alignment and stable probe positioning even in tight spaces. -

What operating temperature range does it support?

The probe functions reliably from −40 °C to +125 °C, making it suitable for extreme industrial environments. -

Can it withstand high vibration levels without losing accuracy?

Yes, it is rated for up to 20 g of vibration in the 10–2000 Hz frequency range, maintaining stable output under severe mechanical stress. -

Does the probe provide a differential signal for noise immunity?

Yes, it outputs a differential voltage signal, which minimizes electromagnetic interference and ensures consistent measurement quality. -

What is the specified insulation resistance?

The probe provides insulation resistance greater than 100 MΩ at 500 V DC, ensuring electrical stability in demanding applications. -

How does it handle electromagnetic or radio-frequency interference?

Its internal shielding and robust design protect the measurement signal from external electromagnetic disturbances. -

Is the probe suitable for continuous operation in corrosive or humid conditions?

Yes, the stainless-steel body and corrosion-resistant finish provide reliable performance in chemically aggressive or high-humidity settings.

Related Models in the Same Series

| Model Number | Description |

|---|---|

| 330196-05-30-05-RU | 3300 XL 8 mm ETR Reverse Mount Probe, 0.5 m length |

| 330196-05-30-10-RU | 3300 XL 8 mm ETR Reverse Mount Probe, 1.0 m length |

| 330196-05-30-20-RU | 3300 XL 8 mm ETR Reverse Mount Probe, 2.0 m length |

| 330196-05-30-30-RU | 3300 XL 8 mm ETR Reverse Mount Probe, 3.0 m length |

| 330196-05-30-90-RU | 3300 XL 8 mm ETR Reverse Mount Probe, 9.0 m length |

| 330196-05-30-12-RU | 3300 XL 8 mm ETR Reverse Mount Probe, 1.2 m length |

Popular Bently Nevada Models

| Model Number | Description |

|---|---|

| 330103-00-12-10-02-00 | 3300 XL 8 mm Proximity Probe |

| 3500/22M | Transient Data Interface for 3500 Series Monitors |

| 3300/16 | 16-Channel Machinery Protection Monitor |

| 3500/42M | Proximitor/Seismic Monitor |

| 330130-040-00 | Extension Cable for Proximity Probe Systems |

| 330104-00-05-10-02-05 | 3300 XL 11 mm Proximity Probe |

Excellent PLC

Excellent PLC