| Company Information | ||||||||

| sales@xmjzjsgs.com | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Overview

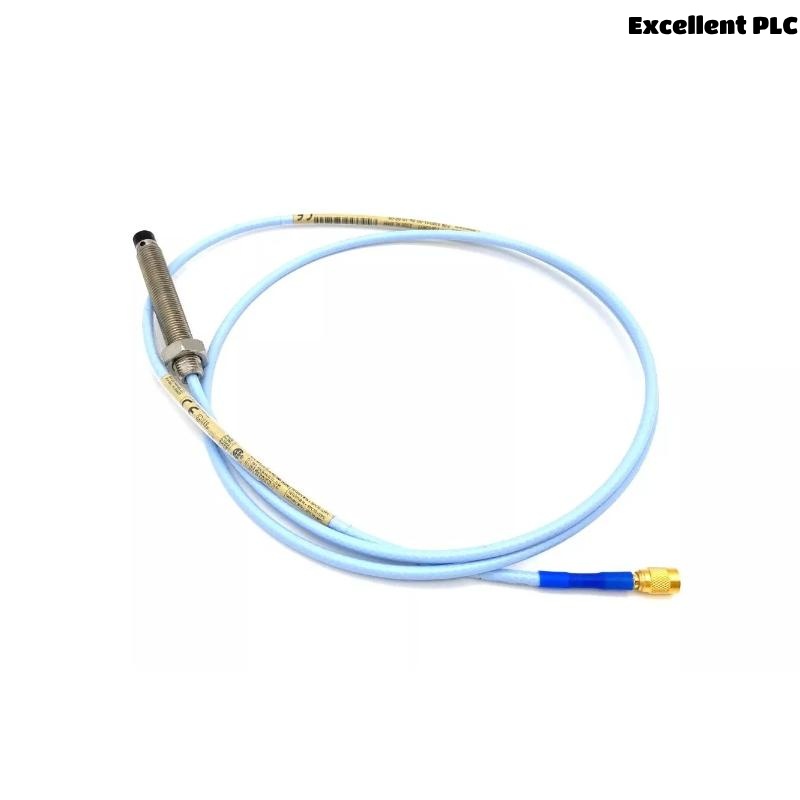

The Bently Nevada 330500-02-00 Velomitor Piezoelectric Velocity Sensor is an advanced, compact sensor designed for continuous monitoring of vibration velocity in critical rotating machinery. As part of Bently Nevada’s renowned Velomitor Series, this sensor provides highly accurate, real-time velocity measurements, contributing to effective machinery protection, predictive maintenance, and increased operational efficiency.

The 330500-02-00 utilizes proven piezoelectric sensing technology, converting mechanical vibrations into an electrical signal proportional to velocity (RMS or peak). Its robust stainless steel housing, high EMI immunity, and broad operating temperature range make it ideal for harsh industrial environments where equipment reliability is paramount.

Key Features

-

Piezoelectric velocity sensor for precise vibration measurement

-

Converts mechanical vibrations to proportional electrical velocity signals

-

Compact, rugged design with stainless steel construction

-

Factory-calibrated for consistent measurement accuracy

-

Broad frequency response for effective condition monitoring

-

Electrical isolation and excellent EMI/RFI protection

-

Wide dynamic range suitable for high-vibration applications

-

Compatible with Bently Nevada monitoring platforms, including 3500 Series

-

Ideal for continuous online monitoring of motors, pumps, fans, and compressors

-

Easy installation with multiple mounting options

Technical Specifications

| Parameter | Description |

|---|---|

| Product Name | Bently Nevada Velomitor Piezoelectric Velocity Sensor |

| Model Number | 330500-02-00 |

| Sensor Type | Piezoelectric Velocity Sensor |

| Measurement Output | Vibration Velocity (mm/s RMS or in/s RMS) |

| Sensitivity | 4.0 mV/mm/s (100 mV/in/s) nominal |

| Frequency Response (±3 dB) | 4.5 Hz to 5 kHz |

| Dynamic Range | ±50 g peak |

| Transverse Sensitivity | Less than 5% of primary axis sensitivity |

| Electrical Isolation | Case isolated, >100 MΩ at 500 VDC |

| Operating Voltage | 18 to 30 VDC |

| Output Impedance | Less than 100 Ohms |

| Temperature Range (Operating) | -40°C to +121°C |

| Humidity Range | 95% Non-condensing |

| Housing Material | Stainless Steel |

| Connector Type | MIL-C-5015 2-pin connector (integral cable optional) |

| Mounting Type | 1/4-28 UNF tapped hole or adhesive base options |

| Dimensions | Diameter 25.3 mm |

| Weight | 0.142kg |

| Certifications | CE, RoHS compliant; ATEX/IECEx versions available (upon request) |

Product Advantages

-

Accurate Velocity Measurements: Provides reliable vibration data critical for machinery health assessment

-

Rugged Construction: Stainless steel housing ensures durability in harsh industrial conditions

-

Wide Frequency Response: Covers a broad range of vibration frequencies for effective fault detection

-

EMI/RFI Protection: Robust shielding and electrical isolation ensure clean, interference-free signals

-

Compact and Lightweight: Allows for easy integration in space-constrained equipment areas

-

Long Service Life: Solid-state piezoelectric design minimizes maintenance and replacement needs

-

Flexible Installation: Multiple mounting configurations simplify sensor placement on various machinery

-

Factory-Calibrated Performance: Ensures reliable, consistent output across installations

-

Global Standards Compliance: Certified for use in industrial and potentially hazardous environments

-

Predictive Maintenance Support: Enables early fault detection, reducing downtime and repair costs

Industry Applications

The Bently Nevada 330500-02-00 Velomitor Piezoelectric Velocity Sensor is widely deployed in industries that rely on precise vibration monitoring to safeguard rotating equipment:

-

Power Generation: Monitoring turbines, generators, and auxiliary equipment

-

Oil and Gas: Vibration monitoring of compressors, pumps, and critical rotating machinery

-

Petrochemical and Refining: Ensuring safe, efficient operation of pumps, motors, and fans

-

Manufacturing: Condition monitoring of production machinery, motors, and conveyors

-

Metals and Mining: Vibration protection for mills, crushers, and heavy-duty equipment

-

Water and Wastewater Treatment: Continuous monitoring of pumps and rotating systems

-

Marine and Offshore: Monitoring engines, propulsion systems, and auxiliary machinery

-

Pulp and Paper: Detecting abnormalities in rollers, drives, and rotating equipment

Frequently Asked Questions (FAQ)

Q1: What does the 330500-02-00 measure?

It measures vibration velocity, providing an electrical signal proportional to the mechanical vibrations of rotating machinery.

Q2: What sensing technology is used?

The sensor uses advanced piezoelectric technology for reliable, solid-state velocity measurement.

Q3: Can it withstand harsh industrial conditions?

Yes, its stainless steel construction, electrical isolation, and wide temperature range make it ideal for harsh environments.

Q4: Is it suitable for continuous online monitoring?

Absolutely. It is designed for continuous, real-time monitoring of vibration levels in critical equipment.

Q5: How is it powered?

The sensor operates on 18 to 30 VDC supplied by the monitoring system.

Q6: Is it compatible with Bently Nevada monitoring platforms?

Yes, it integrates seamlessly with Bently Nevada systems, including the 3500 Series.

Q7: What mounting options are available?

It can be mounted using a 1/4-28 UNF tapped hole or adhesive base, offering flexibility for installation.

Q8: How is electrical noise handled?

The sensor incorporates excellent shielding and electrical isolation to minimize EMI/RFI interference.

Q9: Is it certified for hazardous locations?

ATEX and IECEx certified versions are available; contact the manufacturer for details.

Q10: What is its operating temperature range?

The sensor operates reliably between -40°C and +121°C, suitable for most industrial applications.

Recommended Related Models

| Model Number | Description |

|---|---|

| 330500-01-04 | Standard Velomitor Piezoelectric Velocity Sensor |

| 330500-02-01 | Velomitor Sensor with Alternate Mounting Options |

| 330505-02-12-10-02-00 | Industrial Accelerometer for Harsh Environments |

| 330400-02-12-10-02-00 | Velomitor Piezoelectric Velocity Sensor with Integrated Cable |

| 330101-00-08-10-02-05 | Bently Nevada 3300 XL 8mm Proximity Probe for Shaft Monitoring |

| 330180-91-05 143945-01 | Bently Nevada 3300 XL Proximitor Sensor |

Popular Bently Nevada Monitoring Products

| Model Number | Description |

|---|---|

| 3500/22M-01-01-00 | 3500 Series System Interface Module |

| 3500/42M-01-00 | 3500 Series Vibration Monitoring Module |

| 3500/15-05-05-00 | 3500 Series Power Supply for Monitoring Racks |

| 330130-040-00-00 | 3300 XL Extension Cable for Proximity Probe Systems |

| 330104-00-05-10-02-00 | 3300 XL 8mm Proximity Probe, 5 Meter Cable |

| 330750-00-50-50-01 | Bently Nevada Industrial Accelerometer |

Excellent PLC

Excellent PLC