| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Description

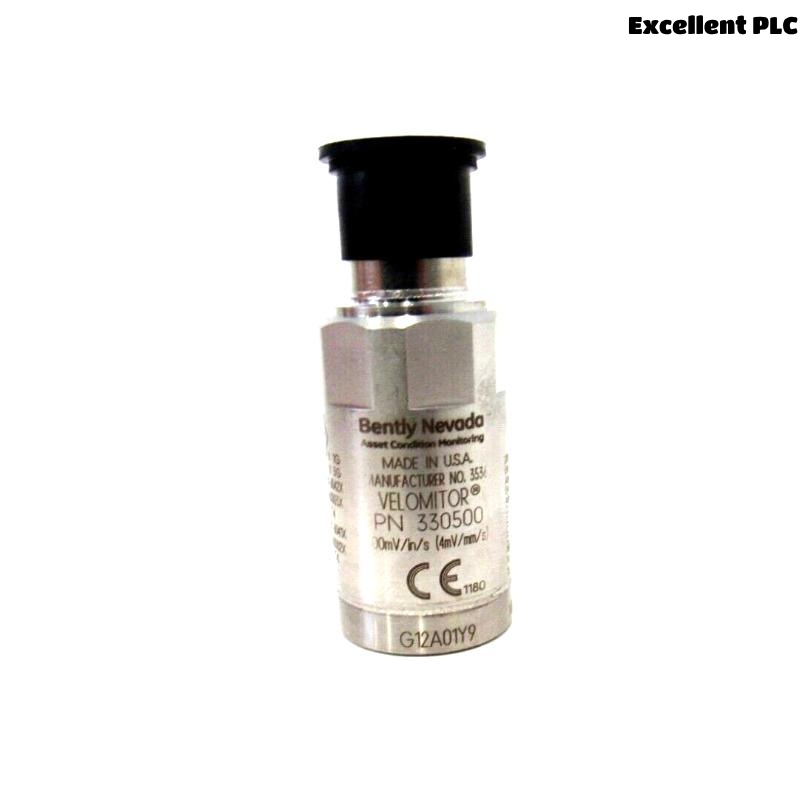

The Bently Nevada 330500-03-02 Velomitor Piezo-velocity Sensor is an industrial-grade sensor engineered to monitor absolute vibration levels in machine casings, bearing housings, and structures. Utilizing solid-state piezoelectric technology with embedded electronics, it offers high reliability without mechanical wear, making it ideal for long-term vibration monitoring in harsh industrial environments.

Technical Specifications

| Parameter | Value |

|---|---|

| Sensitivity | 3.94 mV/mm/s (100 mV/in/s) ±5% |

| Frequency Response | 4.5 Hz to 5 kHz (±3 dB); 6.0 Hz to 2.5 kHz (±0.9 dB) |

| Velocity Range | 1270 mm/s (50 in/s) peak |

| Amplitude Linearity | ±2% up to 152 mm/s (6 in/s) |

| Mounted Resonant Frequency | >12 kHz |

| Temperature Range | -55°C to +121°C |

| Shock Survivability | 5,000 g peak |

| Relative Humidity | Up to 100% non-submerged |

| Output Bias Voltage | -12 ±3.0 VDC |

| Dynamic Output Impedance | <2400 Ω |

| Noise Floor | 0.004 mm/s (160 μin/s) rms |

| Transverse Sensitivity | <5% |

| Grounding | Case isolated |

| Connector Type | 2-pin MIL-C-5015 hermetically-sealed |

| Material | 316L stainless steel |

| Weight | 0.142 kg (5.0 oz) |

| Sensor Head Diameter | 25.3 mm (0.995 in) |

| Sensor Height | 63.2 mm (2.49 in) |

Applications

-

Monitoring of bearing housings and machine casings

-

Suitable for rotating machinery (motors, compressors, turbines)

-

Ideal for harsh environments including high temperatures and shocks

-

Predictive maintenance and condition monitoring

-

Applications in oil & gas, power generation, and marine industries

Product Advantages

-

Solid-state design with no moving parts

-

Reliable performance in extreme temperatures and conditions

-

High accuracy and broad frequency response

-

Minimal maintenance required

-

Certified for hazardous environments (ATEX, IECEx, CSA)

-

Long cable runs without signal degradation (up to 305 m)

FAQ – Frequently Asked Questions

Q1: What is the primary function of the 330500-03-02 sensor?

A1: It measures absolute casing vibration for machinery condition monitoring.

Q2: Can this sensor be installed in any orientation?

A2: Yes, it can be mounted vertically, horizontally, or at any angle.

Q3: What is the material of the sensor housing?

A3: The sensor is made of 316L stainless steel for corrosion resistance.

Q4: What is the output sensitivity of the sensor?

A4: The sensor provides 3.94 mV/mm/s (100 mV/in/s) ±5% sensitivity.

Q5: Is the 330500-03-02 suitable for hazardous locations?

A5: Yes, it has ATEX, IECEx, and CSA approvals for hazardous areas.

Q6: What is the maximum cable length supported?

A6: It supports up to 305 meters (1,000 feet) without signal degradation.

Q7: What is the operating temperature range?

A7: It operates from -55°C to +121°C.

Q8: Does it require external signal conditioning?

A8: No, it has integrated electronics, so no external conditioning is needed.

Q9: What is the mounting torque specification?

A9: Recommended torque is 24–40 in-lb (32–46 kg·cm).

Q10: Is the sensor immune to electromagnetic interference?

A10: Yes, it has magnetic field susceptibility <51 min/s/gauss at 50–60 Hz.

Recommended Related Models

| Model Number | Description | Frequency Range | Sensitivity | Material |

|---|---|---|---|---|

| 330525 | Velomitor Piezo-velocity Sensor (NPT) | 4.5 Hz – 5 kHz | 100 mV/in/s | 316L Stainless Steel |

| 330400 | General Purpose Velomitor Sensor | 4.5 Hz – 2.5 kHz | 3.94 mV/mm/s | Stainless Steel |

| 330450 | High Temperature Velomitor Sensor | 5 Hz – 2.5 kHz | 3.94 mV/mm/s | Stainless Steel |

| 330750 | Top Exit Velomitor Sensor | 4.5 Hz – 5 kHz | 100 mV/in/s | 316L Stainless Steel |

| 330200 | Low Frequency Velomitor Sensor | 2 Hz – 2 kHz | 3.94 mV/mm/s | Stainless Steel |

| 107770 | Velomitor Sensor + Housing (CENELEC) | 4.5 Hz – 5 kHz | 100 mV/in/s | 316L Stainless Steel |

Popular Bently Nevada Models

| Model Number | Product Type | Application | Frequency Range | Weight |

|---|---|---|---|---|

| 3500/42M | Proximitor/Seismic Monitor | Shaft vibration monitoring | Up to 10 kHz | ~0.5 kg |

| 330104-00-06-10-11 | 8mm Proximity Probe | Shaft displacement monitoring | DC to 10 kHz | ~0.1 kg |

| 330130-040-00-00 | Extension Cable | Probe to monitor connection | N/A | ~0.3 kg |

| 330180-91-CN | Proximitor Sensor | Position/vibration detection | 0 to 10 kHz | ~0.15 kg |

| 3500/15 | Power Supply Module | Rack power management | N/A | ~1.3 kg |

| 3500/22M | Transient Data Interface | Advanced diagnostics | Up to 20 kHz | ~0.8 kg |

Excellent PLC

Excellent PLC