| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

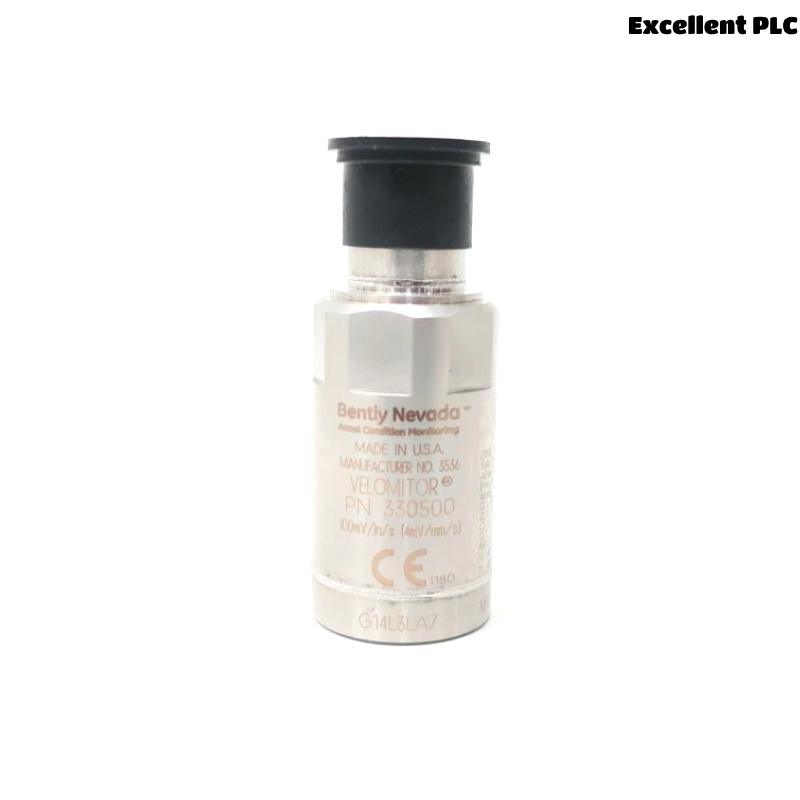

The Bently Nevada 330500-04-00 Velomitor Piezo-Velocity Sensor is a high-performance vibration monitoring sensor designed to measure velocity in rotating machinery applications. It is a key component in the Bently Nevada vibration monitoring system, ensuring the reliable operation of critical machines by continuously measuring vibrations in real-time. This sensor is part of the Velomitor series, which utilizes piezoelectric technology to provide accurate velocity measurements over a wide frequency range.

The 330500-04-00 sensor is specifically designed for high-speed, high-precision vibration monitoring. It is commonly used in industries such as power generation, oil and gas, manufacturing, and heavy machinery, where precise vibration data is critical for ensuring optimal machine health, preventing failure, and improving the longevity of mechanical systems.

With its compact design, robust build, and exceptional performance, the Velomitor sensor is ideal for use in both new and retrofit applications, providing real-time data to help operators make informed decisions about equipment maintenance.

Product Specifications

| Parameter | Specification |

|---|---|

| Model | 330500-04-00 |

| Type | Piezo-Velocity Sensor |

| Measurement Range | 0.2 to 2000 mm/s |

| Frequency Range | 2 Hz to 10 kHz |

| Operating Temperature | -40°C to +120°C |

| Output Signal | 4-20 mA DC |

| Power Supply | 18-30 V DC |

| Mounting Type | Threaded (M6) |

| Weight | 0.142 kg |

| Diameter | 25.3 mm |

| Housing Material | Stainless Steel |

| Environmental Protection | IP67 |

Product Applications

The Bently Nevada 330500-04-00 Velomitor Piezo-Velocity Sensor is used across several industries for monitoring machinery and ensuring the smooth operation of critical equipment. Some of its primary applications include:

-

Rotating Machinery Monitoring

The sensor is widely used in monitoring the health of rotating equipment such as motors, turbines, pumps, and compressors by detecting vibrations and measuring velocity levels. -

Power Generation

In power plants, the sensor is essential for monitoring the vibration of generators, turbines, and other key equipment, helping to prevent unplanned downtime and extend the life of critical systems. -

Oil and Gas

Used in oil rigs and refineries, the Velomitor sensor helps monitor machinery in harsh conditions, providing real-time data to ensure equipment is operating within safe vibration limits. -

Manufacturing and Heavy Machinery

In manufacturing plants, the sensor helps monitor large machines such as mills, conveyors, and presses, detecting any deviations that could indicate potential failure or maintenance needs. -

HVAC Systems

Used in HVAC systems to monitor fan speeds, vibration levels in compressors, and other moving parts, ensuring that the system remains efficient and reliable. -

Aerospace and Defense

The sensor is also utilized in aerospace applications where accurate vibration monitoring is critical for maintaining the integrity of high-performance systems and ensuring safety.

Product Advantages

-

High Accuracy: The Velomitor sensor delivers precise velocity measurements, allowing for accurate detection of changes in vibration, which can indicate potential mechanical issues.

-

Wide Measurement Range: It covers a broad range of vibration frequencies (2 Hz to 10 kHz) and velocities (0.2 to 2000 mm/s), making it suitable for a wide variety of machinery applications.

-

Robust Construction: Built with a stainless-steel housing, the sensor is designed to withstand harsh industrial environments, offering durability and longevity.

-

Easy Installation: The threaded mounting design (M6) allows for straightforward installation in a variety of machinery setups.

-

Environmental Protection: The IP67-rated sensor offers excellent protection against dust and water, ensuring reliable performance even in challenging environmental conditions.

-

Real-Time Data Transmission: With its 4-20 mA DC output signal, the sensor provides real-time data to the connected monitoring system, enabling timely detection of potential issues.

Frequently Asked Questions (FAQs)

-

What is the measurement range of the Bently Nevada 330500-04-00 Velomitor sensor?

The sensor has a measurement range of 0.2 to 2000 mm/s. -

What is the frequency range of the sensor?

The frequency range of the sensor is 2 Hz to 10 kHz. -

What output signal does the sensor provide?

The sensor outputs a 4-20 mA DC signal. -

What is the operating temperature range for the Velomitor sensor?

The sensor can operate within a temperature range of -40°C to +120°C. -

How is the sensor mounted?

The sensor is mounted using a threaded M6 connection. -

What is the weight of the Bently Nevada 330500-04-00 sensor?

The sensor weighs 0.142 kg. -

What is the housing material of the sensor?

The sensor has a stainless-steel housing, providing durability and protection against corrosion. -

What environmental protection does the sensor have?

The sensor is IP67 rated, offering protection against dust and water. -

What power supply is required for the sensor?

The sensor requires a power supply of 18-30 V DC. -

What industries benefit from using the Bently Nevada 330500-04-00 sensor?

The sensor is used in power generation, oil and gas, manufacturing, heavy machinery, HVAC, and aerospace industries.

Related Models from the Bently Nevada Velomitor Series

| Model | Measurement Range | Frequency Range | Output Signal | Weight | Application |

|---|---|---|---|---|---|

| 330500-02-00 | 0.2 to 1000 mm/s | 2 Hz to 10 kHz | 4-20 mA DC | 0.23 kg | Low-speed machinery, pumps |

| 330500-05-00 | 0.2 to 2000 mm/s | 2 Hz to 10 kHz | 4-20 mA DC | 0.28 kg | High-speed machinery, turbines |

| 330500-06-00 | 0.1 to 1000 mm/s | 2 Hz to 10 kHz | 4-20 mA DC | 0.26 kg | Compressors, large motors |

| 330500-03-00 | 0.2 to 1500 mm/s | 2 Hz to 10 kHz | 4-20 mA DC | 0.24 kg | Vibration monitoring in plants |

| 330500-07-00 | 0.5 to 2000 mm/s | 2 Hz to 10 kHz | 4-20 mA DC | 0.30 kg | Fans, high-torque motors |

| 330500-08-00 | 0.2 to 1500 mm/s | 2 Hz to 10 kHz | 4-20 mA DC | 0.25 kg | Gas turbines, energy systems |

Popular Models from Bently Nevada

| Model | Measurement Range | Frequency Range | Output Signal | Weight | Application |

|---|---|---|---|---|---|

| 3300 XL | 0.05 to 2000 mm/s | 2 Hz to 10 kHz | 4-20 mA DC | 0.32 kg | Industrial monitoring systems |

| 3500/42M | 0.1 to 1000 mm/s | 2 Hz to 10 kHz | 4-20 mA DC | 1.1 kg | Gas turbines, critical systems |

| 330500-10-00 | 0.2 to 2000 mm/s | 2 Hz to 10 kHz | 4-20 mA DC | 0.27 kg | Compressors, power generation |

| 3300/25 | 0.05 to 1000 mm/s | 2 Hz to 10 kHz | 4-20 mA DC | 0.38 kg | Fans, HVAC systems |

| 3500/53 | 0.1 to 1500 mm/s | 2 Hz to 10 kHz | 4-20 mA DC | 1.3 kg | Pumps, turbines, mechanical systems |

| 330500-01-00 | 0.2 to 1500 mm/s | 2 Hz to 10 kHz | 4-20 mA DC | 0.23 kg | Low-speed motors, generators |

Excellent PLC

Excellent PLC