| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Overview

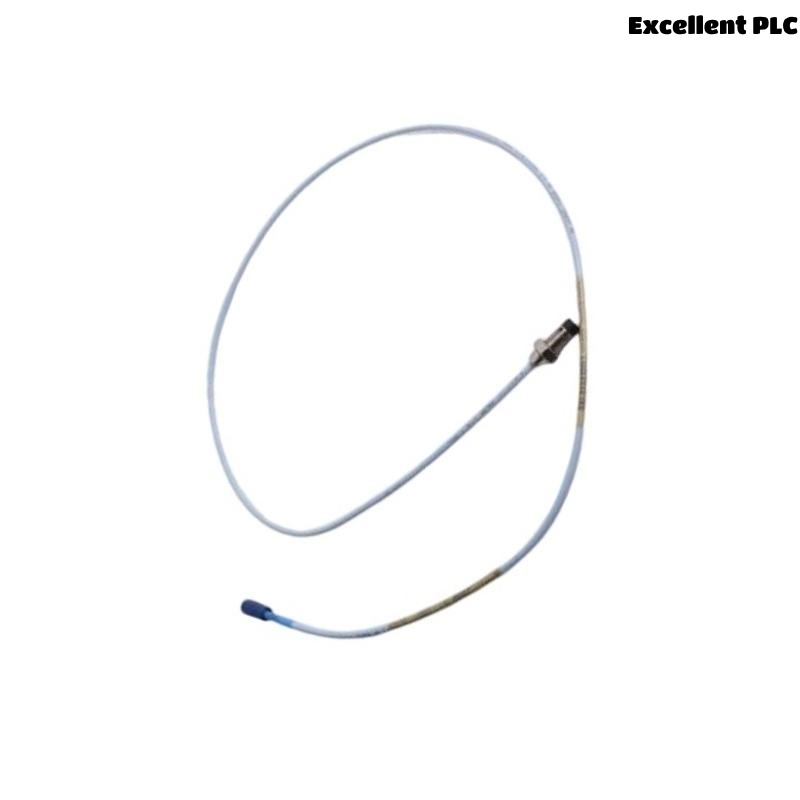

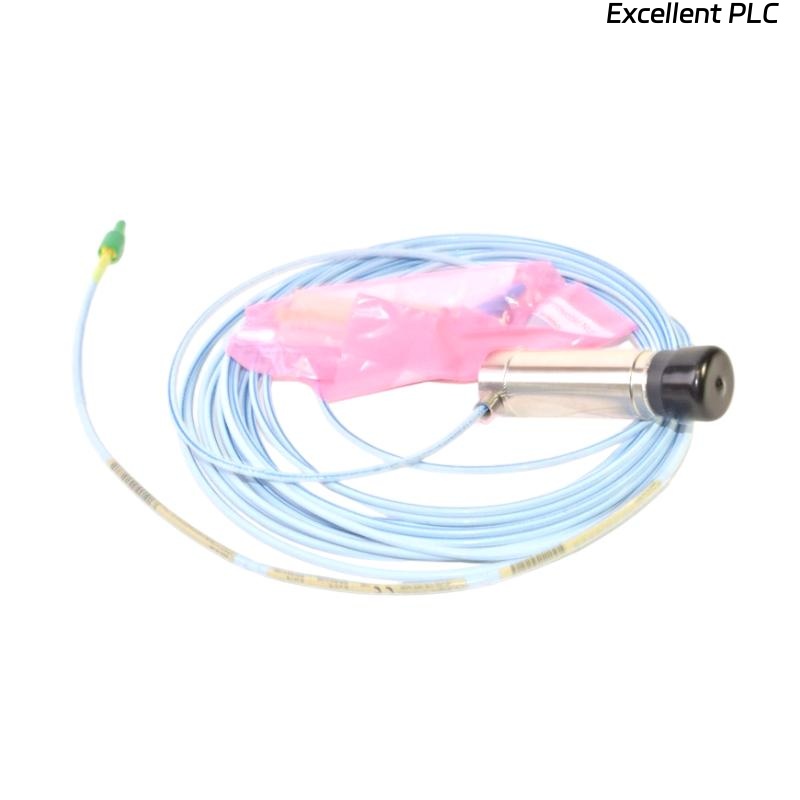

The Bently Nevada 330701-00-30-10-02-05 3300 XL 11 mm Eddy-Current Probe is a precision industrial sensor designed for use in vibration monitoring and machinery protection systems. Engineered to detect minute changes in position or vibration of rotating machinery, this probe operates using the eddy-current principle, ensuring high reliability and accuracy even in harsh industrial environments.

Specifically crafted for critical rotating equipment such as turbines, compressors, and motors, the 3300 XL series probes offer exceptional durability and consistent performance. The 11 mm probe tip diameter allows for optimal sensitivity and spatial resolution, making it ideal for detailed condition monitoring.

Technical Specifications

| Parameter | Specification |

|---|---|

| Model Number | 330701-00-30-10-02-05 |

| Series | 3300 XL |

| Probe Type | Eddy-Current Displacement Probe |

| Probe Diameter | 11 mm |

| Dimensions | Total Length : 1.0 meter |

| Connector Type | MS Connector |

| Operating Temperature | -40°C to +120°C |

| Storage Temperature | -55°C to +125°C |

| Vibration Frequency Range | DC to 20 kHz |

| Target Material | Conductive metals |

| Sensitivity | Typical 10 mV/mil (0.394 mV/µm) |

| Weight | 0.323 kg |

| Housing Material | Stainless Steel |

| Mounting Style | Threaded probe body |

| Environmental Protection | IP67 |

Applications

The 3300 XL 11 mm Eddy-Current Probe is used primarily in machinery protection and condition monitoring systems, including:

-

Turbine shaft vibration monitoring in power plants

-

Compressor vibration and position sensing in petrochemical plants

-

Generator shaft displacement measurement

-

Monitoring pumps and motors for early detection of mechanical faults

-

Industrial gearbox vibration analysis

-

Turbomachinery diagnostic and predictive maintenance

Advantages

-

High Precision and Sensitivity: The 11 mm probe tip combined with eddy-current technology delivers highly accurate vibration and displacement measurements, essential for early fault detection.

-

Robust Construction: Stainless steel housing and sealed design ensure excellent resistance to dust, moisture, and harsh industrial environments.

-

Wide Temperature Range: Suitable for use in extreme temperature conditions, enabling deployment in diverse industrial settings.

-

Ease of Installation: Standard threaded probe body and MS connector allow straightforward integration into existing monitoring systems.

-

Long Cable Length: Factory-fitted cable length provides installation flexibility without additional connectors that can compromise signal integrity.

-

Compatibility: Fully compatible with the Bently Nevada 3500 and other 3300 series monitoring systems for seamless integration.

-

Reduced Maintenance Costs: Durable materials and construction minimize probe replacement frequency and system downtime.

Frequently Asked Questions (FAQ)

-

What is the operating principle of the 3300 XL Eddy-Current Probe?

It operates by inducing eddy currents in the conductive target material; changes in distance affect the current and output signal. -

What types of machinery are best suited for this probe?

It is ideal for rotating equipment such as turbines, compressors, motors, and pumps. -

Can this probe measure both displacement and vibration?

Yes, it provides displacement measurements and can be used for vibration analysis within its frequency range. -

What is the maximum operating temperature for the probe?

The probe can operate safely up to +120°C continuously. -

How long is the cable attached to the probe?

The standard cable length is 1 meters; custom lengths are available upon request. -

Is the probe resistant to harsh environments?

Yes, it is IP67 rated, providing protection against dust and water ingress. -

What materials can the probe detect?

It detects conductive metals such as steel, aluminum, and copper. -

How is the probe installed?

It is mounted via a threaded probe body into the machine housing and connected using an MS connector. -

What maintenance is required for the probe?

Routine inspection and cleaning are recommended; the probe itself is designed to require minimal maintenance. -

Is the probe compatible with other monitoring systems besides Bently Nevada?

While optimized for Bently Nevada systems, it may be compatible with other systems that accept similar signal and connector standards, but confirmation is advised.

Related Models

| Model Number | Description |

|---|---|

| 330701-00-30-10-01-05 | 3300 XL 11 mm Eddy-Current Probe |

| 330701-00-30-10-02-00 | 3300 XL 11 mm Eddy-Current Probe, no connector |

| 330701-00-20-10-02-05 | 3300 XL 11 mm Probe |

| 330701-00-14-10-02-05 | 3300 XL 11 mm Probe |

| 330701-00-30-12-02-05 | 3300 XL 12 mm Probe |

| 330701-00-11-10-02-05 | 3300 XL 11 mm Probe |

Popular Bently Nevada Models

| Model Number | Description |

|---|---|

| 330104-01-05-50-02-00 | 3300 XL 8 mm Proximity Probe |

| 330171-00-12-10-01-05 | 3300 5 mm Proximity Probe |

| 330173-00-09-10-02-CN | 3300 5 mm Proximity Probe |

| 330701-00-20-10-02-05 | 3300 XL 11 mm Eddy-Current Probe (alternate cable) |

| 330130-045-01-05 | 3300 XL Standard Extension Cord |

| 330101-00-14-10-02-05 | 3300 XL 8 mm Eddy-Current Probe |

Excellent PLC

Excellent PLC