| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

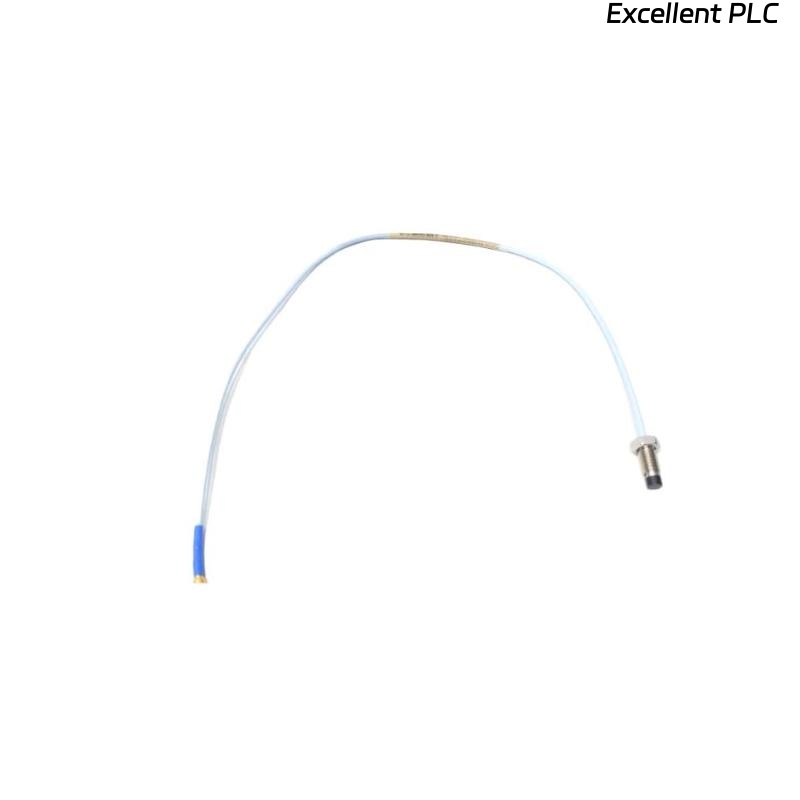

The Bently Nevada 330702-00-30-10-02-00 3300 XL 11mm Proximity Probes is a high-precision, non-contact displacement sensor designed for industrial machinery monitoring. Part of the 3300 XL series, it provides accurate measurement of shaft vibration and position in rotating equipment. Engineered for reliability and robustness, the probe delivers consistent performance under harsh conditions, including high temperature, vibration, and electromagnetic interference. Its reverse mount design allows flexible installation in confined spaces and supports integration with Bently Nevada 3300 XL monitoring systems for real-time machinery protection, diagnostics, and condition monitoring.

Product Specifications

| Parameter | Description |

|---|---|

| Model Number | 330702-00-30-10-02-00 |

| Series | 3300 XL Proximity Probes |

| Measurement Range | 11 mm non-contact displacement |

| Sensitivity | 5 mV/µm typical |

| Frequency Response | DC to 10 kHz |

| Insulation Resistance | >100 MΩ at 500 V DC |

| Dielectric Strength | 2.5 kV AC for 1 minute |

| Operating Temperature | –40°C to +120°C |

| Housing Material | Stainless steel |

| Probe Tip Material | Ceramic tip with high abrasion resistance |

| Output Compatibility | Compatible with Bently Nevada 3300 XL Proximitor sensors |

| Shock/Vibration Rating | Up to 20 g, 10–2000 Hz |

| Total Length | 1.0 meter |

| Weight | 0.17 kg |

| Mounting Style | Reverse mount for flexible installation |

Applications

-

Turbomachinery Monitoring – Measures shaft vibration and displacement in turbines, compressors, and generators.

-

Critical Rotating Equipment – Protects high-value machinery by providing real-time condition data.

-

Process Industries – Supports vibration monitoring in petrochemical, oil & gas, and power plants.

-

Condition-Based Maintenance – Enables early detection of rotor misalignment, imbalance, and wear.

-

High-Speed Rotating Equipment – Monitors rapid changes in shaft position for protective actions.

-

Retrofit Installations – Reverse mount design allows use in existing machinery with limited access.

Advantages

-

High Accuracy – Provides precise non-contact displacement measurement for machinery protection.

-

Robust Construction – Stainless steel housing and ceramic tip withstand harsh industrial environments.

-

Flexible Installation – Reverse mount design accommodates confined spaces and complex equipment layouts.

-

Seamless Integration – Works directly with 3300 XL Proximitor sensors and monitoring systems.

-

Reliable Performance – Operates consistently under vibration, shock, and electromagnetic interference.

-

Preventive Maintenance Support – Provides data critical for condition monitoring and predictive maintenance strategies.

Frequently Asked Questions (FAQ)

-

How does the 330702-00-30-10-02-00 measure shaft vibration?

It uses an eddy current principle to detect shaft displacement without physical contact, producing voltage proportional to distance. -

Is this probe compatible with all 3300 XL Proximitor sensors?

Yes, it is fully compatible with the 3300 XL Proximitor series, ensuring seamless integration. -

Can it operate in high-vibration environments?

Yes, it is rated for up to 20 g vibration in the 10–2000 Hz range, suitable for industrial rotating equipment. -

What types of mounting does it support?

The reverse mount configuration allows installation in restricted or confined spaces while maintaining alignment. -

Does the probe provide real-time data for condition monitoring?

Yes, it outputs continuous analog signals compatible with 3300 XL monitoring systems for real-time diagnostics. -

How is electromagnetic interference managed?

The sensor design and shielding minimize EMI effects, ensuring accurate measurement in electrically noisy environments. -

Can it detect both radial and axial displacement?

The probe primarily measures radial shaft displacement but can detect axial movement indirectly when paired with proper system configuration. -

What is the typical sensitivity of this probe?

The probe typically outputs 5 mV per micrometer of displacement, ensuring high-resolution measurement. -

Is the probe suitable for retrofitting older machinery?

Yes, the reverse mount and standardized interface make it suitable for retrofitting and upgrading existing equipment. -

How does it contribute to machinery protection?

By providing precise vibration and displacement data, the probe enables early fault detection, reducing unplanned downtime and potential equipment damage.

Related Models – Same Series

| Model | Description |

|---|---|

| 330195-02-12-10-CN | 3300 XL 8 mm ETR reverse mount probe |

| 330195-02-12-50-00 | 3300 XL 8 mm ETR reverse mount probe with longer cable |

| 330196-05-30-10-RU | 3300 XL 8 mm ETR reverse mount probe for high-temperature areas |

| 330196-05-30-50-05 | 3300 XL 8 mm ETR reverse mount probe with extended configuration |

| 330701-00-10-10-11-05 | 3300 XL 11 mm standard proximity probe |

| 330702-00-30-50-01-05 | 3300 XL 8 mm proximity probe with different mounting configuration |

Popular Bently Nevada 3300 XL Models

| Model | Description |

|---|---|

| 330525-02-00 | Velomitor XA Piezo-Velocity Sensor |

| 330525-00 | Velomitor XA Piezo-Velocity Sensor |

| 330450-20 | High Temperature Accelerometer |

| 330300-90-00 | High Temperature Proximitor Sensor |

| 330302-000-050-10-90-01-00 | High Temperature Probe |

| 330535-25-01 | Standard Temperature Cable |

Excellent PLC

Excellent PLC