| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

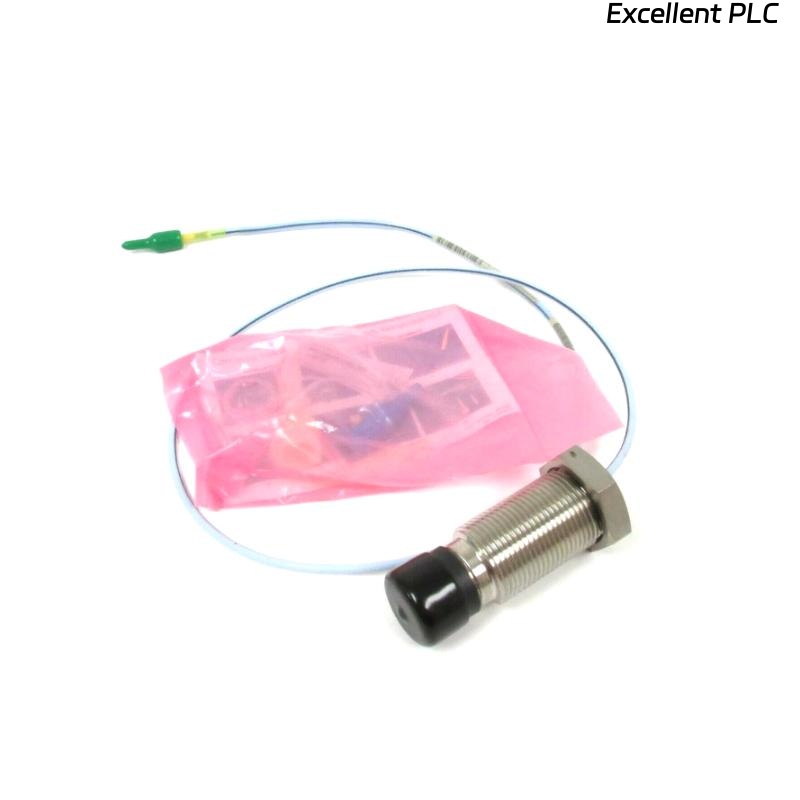

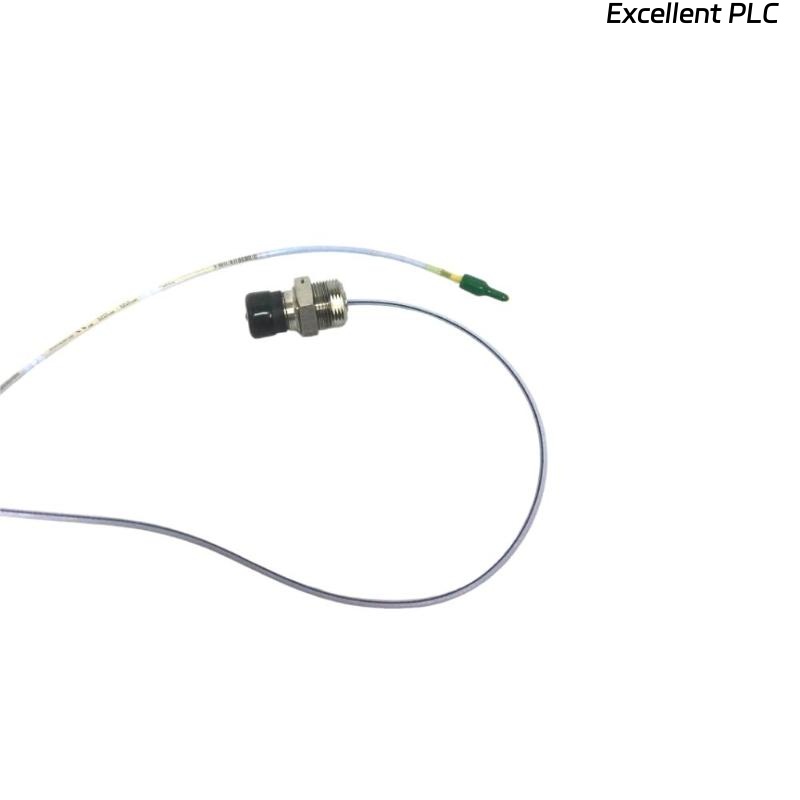

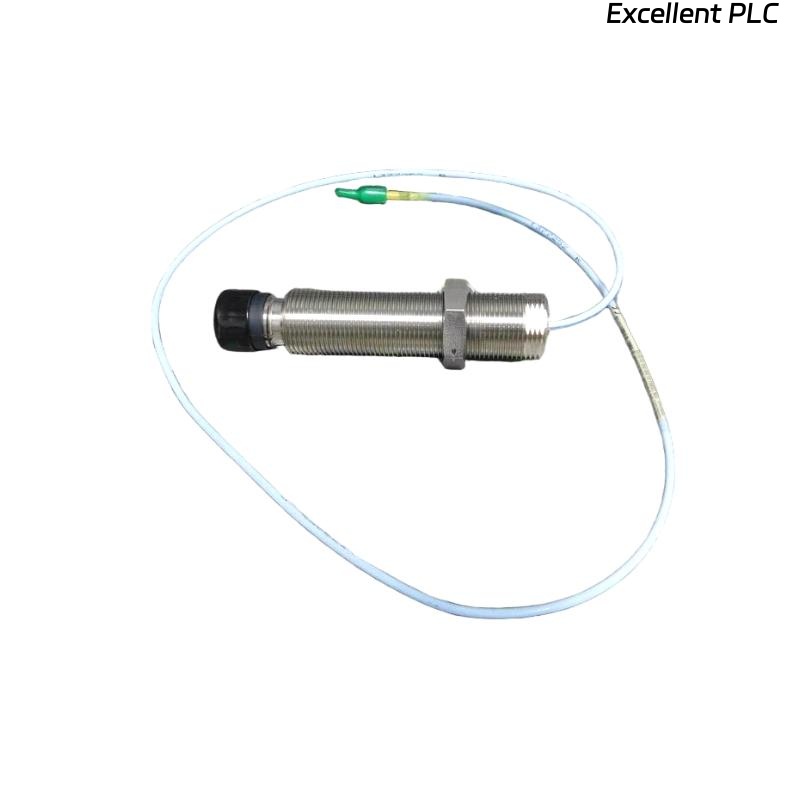

The Bently Nevada 330703-000-090-10-02-CN 3300 XL 11 mm Proximity Probe is a high-precision sensor designed for continuous monitoring of rotating machinery. Part of the trusted 3300 XL series, this probe is engineered to measure shaft vibration and displacement using eddy current sensing technology.

This probe provides reliable, repeatable measurements crucial for early detection of shaft misalignment, imbalance, or mechanical defects in turbines, compressors, pumps, and motors. Its stainless-steel housing offers superior resistance to corrosion, high temperatures, and industrial contaminants, making it suitable for harsh operating conditions. The 330703-000-090-10-02-CN ensures seamless integration with Bently Nevada 3300 XL proximitor systems, supporting predictive maintenance programs and enhancing machinery protection.

Technical Specifications

| Parameter | Specification |

|---|---|

| Model Number | 330703-000-090-10-02-CN |

| Series | 3300 XL |

| Probe Diameter | 11 mm |

| Measurement Type | Proximity / Vibration |

| Sensing Principle | Eddy Current |

| Operating Temperature | -40°C to +120°C |

| Frequency Response | DC to 10 kHz |

| Sensitivity | 50 mV/mil nominal |

| Housing Material | Stainless Steel |

| Cable Type | Shielded |

| Connector Type | 2-pin connector |

| Total Length | 1.0 meter |

| Weight | 0.07 kg |

| Maximum Gap | 0.25 mm |

| Electrical Configuration | Differential / Single-ended |

| Compatible Proximitor | 3300 XL Proximitor Sensor |

Applications

The 330703-000-090-10-02-CN probe is widely used in industrial machinery monitoring and protection systems, including:

-

Turbines: Continuous shaft vibration and displacement monitoring to detect imbalance and misalignment.

-

Compressors: Tracking rotor movement and early detection of mechanical faults.

-

Pumps and Motors: Monitoring shaft vibration, runout, and bearing health.

-

Generators: Ensuring precise shaft positioning and operational stability.

-

Industrial Process Equipment: Integration with 3300 XL systems for predictive maintenance and real-time diagnostics.

-

Gearboxes: Detection of vibration anomalies caused by gear defects or wear.

This probe is critical for machinery protection and predictive maintenance programs that prevent unplanned downtime and reduce maintenance costs.

Advantages

-

High Measurement Accuracy: Reliable detection of shaft displacement and vibration.

-

Durable Construction: Stainless-steel housing resists corrosion and extreme temperatures.

-

Stable Signal: Low-noise output suitable for critical monitoring systems.

-

Wide Frequency Response: DC to 10 kHz for low- and high-frequency vibration detection.

-

Full System Compatibility: Works seamlessly with 3300 XL proximitor sensors and monitoring modules.

-

Easy Installation: Threaded mounting allows secure placement in tight spaces.

-

Predictive Maintenance Support: Provides early warning for machinery faults.

-

Low Maintenance Requirements: Minimal recalibration needed under normal operation.

-

Field-Proven Design: Trusted in power generation, oil & gas, and heavy industry applications.

FAQ

-

What is the operating principle of this probe?

The 330703-000-090-10-02-CN uses eddy current sensing to measure the distance between the probe tip and the conductive shaft surface. -

Which proximitor sensors are compatible with this probe?

It is fully compatible with 3300 XL Proximitor Sensor models 330180 and 330171. -

Can this probe measure both vibration and shaft position?

Yes, it provides accurate measurement of both dynamic vibration and static shaft displacement. -

What type of target material is recommended?

AISI 4140 steel or equivalent conductive metals are recommended for consistent and linear measurement. -

How does the probe handle electrical noise?

The shielded coaxial cable and molded connector design minimize interference and ensure stable signal transmission. -

Is the probe output linear across its measurement range?

Yes, linearity is maintained within ±5% over the full calibrated range. -

What is the proper mounting method?

The probe should be mounted perpendicular to the target surface, with secure thread engagement and a clean, stable shaft surface. -

Can this probe operate in high-temperature environments?

Yes, it can reliably operate at temperatures up to +120°C continuously. -

What is the frequency response of the probe?

The frequency response is DC to 10 kHz, suitable for monitoring low- and high-frequency vibrations. -

Does the probe require recalibration?

Recalibration is generally unnecessary unless system components are replaced or configurations are modified.

Related Models (3300 XL Series)

| Model Number | Description |

|---|---|

| 330703-000-040-10-02-CN | 3300 XL 11 mm probe, standard 1.0 m cable |

| 330703-000-050-10-12-CN | 3300 XL 11 mm probe, 5.0 m cable |

| 330703-000-060-10-02-CN | 3300 XL 11 mm probe, 1.0 m cable |

| 330703-000-070-10-02-CN | 3300 XL 11 mm probe, 1.0 m cable |

| 330703-000-080-10-02-00 | 3300 XL 11 mm probe, 1.0 m cable |

| 330703-000-060-50-12-00 | 3300 XL 11 mm probe, 5.0 m cable |

Popular Bently Nevada Models

| Model Number | Series | Application |

|---|---|---|

| 330180-90-00 | 3300 XL | Proximitor Sensor |

| 330130-040-00 | 3300 XL | Extension Cable |

| 330500-02 | Velomitor | Velocity Measurement Sensor |

| 330780-91-00 | Accelerometer | Vibration Analysis |

| 3500/22M | 3500 Series | Machinery Protection Module |

| 3500/42M | 3500 Series | Dynamic Measurement Module |

Excellent PLC

Excellent PLC