| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

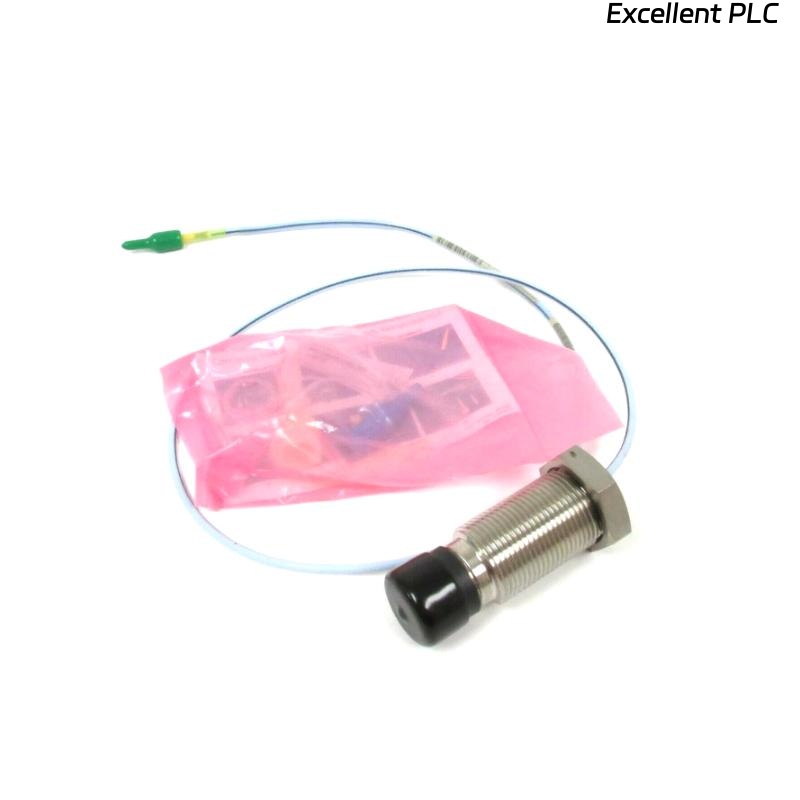

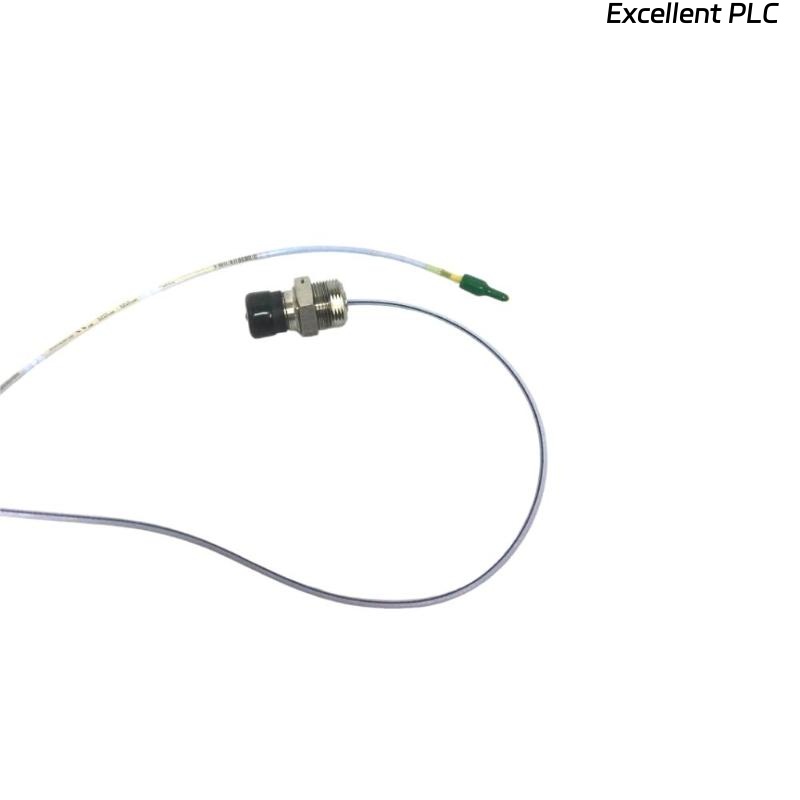

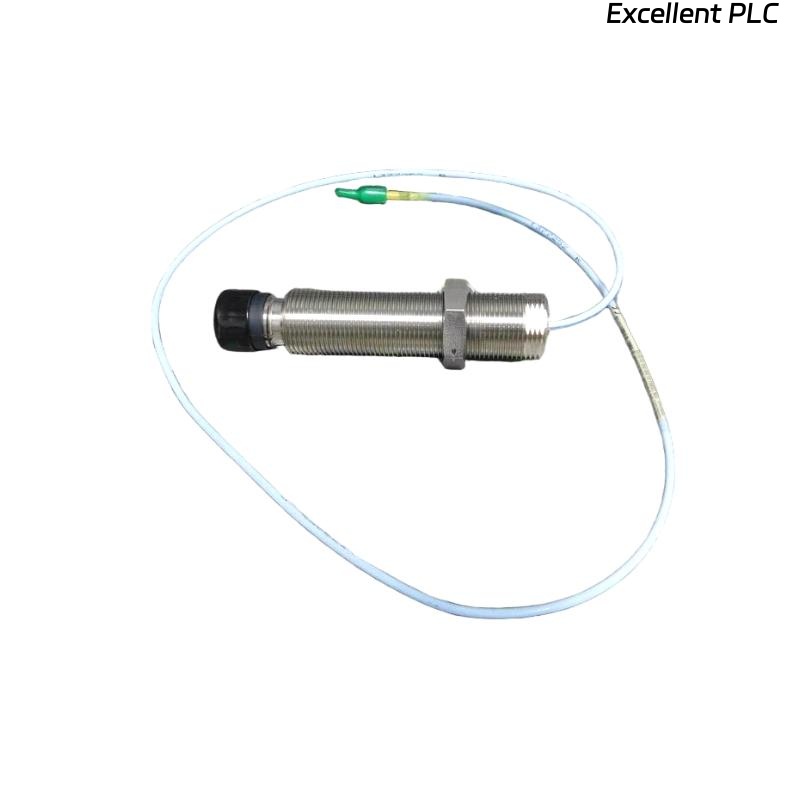

The Bently Nevada 330704-00-050-10-01-05 3300 XL 11 mm Proximity Probe is a high-precision, non-contact displacement sensor designed for continuous monitoring of shaft vibration and rotor position in critical rotating machinery. As part of the renowned 3300 XL series, it combines advanced eddy-current sensing technology with a rugged mechanical design to deliver exceptional measurement accuracy, linearity, and stability in harsh industrial environments. Its stainless-steel construction and robust insulation ensure long-term reliability in power generation, oil and gas, and heavy process industries. Seamless integration with Bently Nevada 3300 XL Proximitor® sensors allows predictive maintenance systems to detect early signs of imbalance, misalignment, or bearing wear, thereby preventing costly downtime.

Product Specifications

| Parameter | Description |

|---|---|

| Model Number | 330704-00-050-10-01-05 |

| Series | 3300 XL Proximity Probes |

| Measurement Range | 11 mm non-contact displacement |

| Sensitivity | 5 mV/µm nominal |

| Frequency Response | DC to 10 kHz |

| Linearity | ±1 % of full scale |

| Operating Temperature | –40 °C to +120 °C |

| Insulation Resistance | >100 MΩ at 500 V DC |

| Dielectric Strength | 2.5 kV AC for 1 minute |

| Housing Material | Stainless steel |

| Probe Tip Material | High-density ceramic |

| Shock/Vibration Rating | Up to 20 g, 10–2000 Hz |

| Output Compatibility | Bently Nevada 3300 XL Proximitor® sensors |

| Mounting Style | Precision threaded mounting |

| Total Length | 1 meter |

| Weight | 0.17 kg |

Applications

-

Turbomachinery Monitoring – Continuous vibration and position tracking for steam, gas, and hydro turbines.

-

Compressors and Pumps – Early detection of bearing wear or rotor imbalance in critical process machinery.

-

Generators and High-Speed Motors – Reliable shaft displacement measurement for power generation systems.

-

Petrochemical and Refinery Equipment – Robust operation in high-temperature and high-vibration environments.

-

Industrial Fans and Blowers – Precise monitoring of radial and axial movement to prevent mechanical failures.

-

Condition Monitoring Systems – Ideal for predictive maintenance programs requiring uninterrupted data.

Advantages

-

Exceptional Accuracy – Maintains ±1 % linearity across the 11 mm measurement range.

-

Durable Design – Stainless-steel housing and ceramic probe tip resist corrosion and thermal stress.

-

Excellent EMI Protection – Multi-layer shielding ensures stable signals in electrically noisy environments.

-

Maintenance Efficiency – Supports early fault detection to minimize unplanned downtime.

-

Proven 3300 XL Technology – Trusted by industries worldwide for continuous 24/7 operation.

-

Seamless System Integration – Pre-calibrated for direct connection with 3300 XL Proximitor® sensors.

Frequently Asked Questions (FAQ)

-

What measurement principle does this probe use?

It uses eddy-current sensing to measure shaft displacement without physical contact. -

How is linearity maintained over the 11 mm range?

Internal calibration and temperature-compensated materials ensure stable, linear output. -

Is it compatible with Bently Nevada 3300 XL Proximitor®?

Yes, it connects directly for precise displacement signals. -

How does it resist electromagnetic interference (EMI)?

Shielded housing and proper grounding reduce susceptibility to electrical noise. -

Can it capture fast vibration transients?

Yes, its frequency response up to 10 kHz allows detection of rapid shaft movements. -

What are the mounting requirements?

Mount on a rigid, flat surface with correct alignment and the recommended probe gap. -

Which shaft materials are supported?

Conductive ferromagnetic shafts are ideal; non-conductive coatings should be avoided. -

How does temperature variation affect the probe?

Low-expansion materials and internal compensation minimize temperature-induced errors. -

What maintenance is recommended?

Check connectors, verify signal, and inspect probe alignment periodically. -

How does the probe handle mechanical vibration and shock?

Robust stainless steel housing and ceramic tip withstand high vibration and shocks.

Related Models – Same Series

| Model | Description |

|---|---|

| 330703-000-040-90-01-00 | 3300 XL 11 mm probe with extended configuration |

| 330703-000-050-10 | 3300 XL 11 mm probe, standard 1 m length |

| 330703-006-100-10-01-00 | 3300 XL 11 mm probe for harsh industrial environments |

| 330703-020-100-90-02-00 | 3300 XL 11 mm probe with extended cable assembly |

| 330704-000-050-90-02 | 3300 XL 11 mm probe with 9 m total length |

| 330702-00-30-10-02-00 | 3300 XL 8 mm proximity probe |

Popular Bently Nevada Models

| Model | Description |

|---|---|

| 330525-02-00 | Velomitor XA Piezo-Velocity Sensor |

| 330450-20 | High-Temperature Accelerometer |

| 330535-25-01 | Standard Temperature Extension Cable |

| 330300-90-00 | High-Temperature Proximitor® Sensor |

| 330302-000-050-10 | High-Temperature Proximity Probe |

| 330525-00 | Velomitor XA Piezo-Velocity Sensor |

Excellent PLC

Excellent PLC