| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

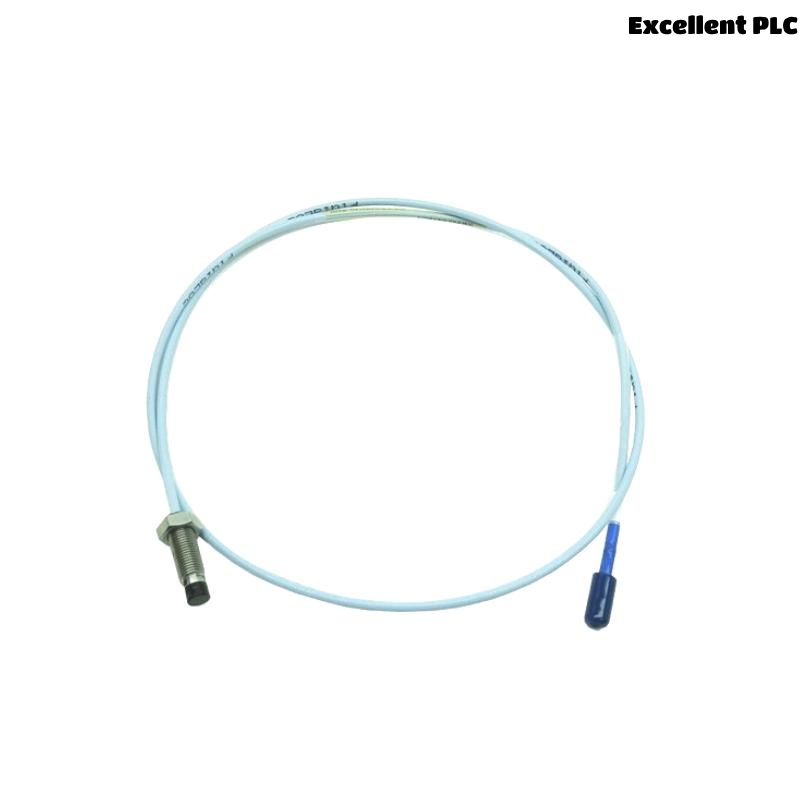

The Bently Nevada 330705-02-18-10-02-00 3300 XL 11 mm Reverse Mount Probe is part of the 3300 XL series from Bently Nevada, renowned for its high-precision vibration and displacement measurement capabilities. Unlike traditional probes, the 3300 XL Reverse Mount Probe is specifically designed for installations where space is limited or where a reverse mounting configuration is necessary. This sensor is primarily used to monitor rotating machinery in industrial settings, providing accurate and real-time feedback on shaft displacement, vibration, and alignment.

Utilizing the reverse mount configuration, the probe is ideal for machinery applications where the traditional forward mount would be difficult or impossible to implement. This probe uses a non-contacting eddy-current technology to measure displacement, which is highly effective for monitoring machinery health without causing wear to the sensor itself. The Bently Nevada 3300 XL Reverse Mount Probe is suitable for a variety of industrial applications, including power generation, oil & gas, manufacturing, and heavy machinery monitoring.

Product Specifications

| Parameter | Specification |

|---|---|

| Model | 330705-02-18-10-02-00 |

| Type | Reverse Mount Proximity Probe |

| Measurement Range | 0 to 11 mm |

| Output Signal | 4-20 mA (Linear) |

| Power Supply | 24 V DC |

| Operating Temperature | -40°C to +85°C |

| Mounting Type | Reverse Mount (customizable) |

| Weight | 0.07 kg |

| Total Length | 1 meter |

| Material | Stainless Steel & Inconel |

| Environmental Protection | IP67 |

Product Applications

The Bently Nevada 330705-02-18-10-02-00 3300 XL 11 mm Reverse Mount Probe is used across several industries for monitoring rotating machinery. Its design makes it especially useful in installations where traditional mounting configurations are impractical. Some of the primary applications include:

-

Rotating Machinery Monitoring

Used for monitoring the displacement and vibration of rotating equipment, including turbines, motors, compressors, and pumps. This helps prevent unexpected breakdowns by identifying issues before they escalate. -

Power Generation

In power plants, the reverse mount probe is used to monitor the condition of critical assets such as turbines, generators, and steam engines, ensuring smooth and continuous operation. -

Oil & Gas Industry

The probe is particularly valuable in harsh environments, such as offshore platforms, oil refineries, and gas plants, to monitor pumps, motors, and compressors that operate in demanding conditions. -

Manufacturing Plants

Widely used in manufacturing plants to monitor the health of machinery such as conveyors, presses, and mills, allowing for proactive maintenance that reduces downtime and maintenance costs. -

HVAC Systems

This probe is also used in HVAC applications for monitoring compressors, fan motors, and other critical rotating parts, ensuring their reliability and efficiency. -

Aerospace and Defense

In aerospace, it helps monitor turbines and other rotating equipment used in aircraft engines and systems, ensuring they are functioning properly to prevent catastrophic failures.

Product Advantages

-

High Precision Measurement: The 3300 XL Reverse Mount Probe delivers precise displacement and vibration data, ensuring that even subtle changes in machine behavior are detected early.

-

Non-Contacting Measurement: The probe uses eddy current technology for non-contact displacement measurement, which helps to prevent wear and ensures that the probe lasts longer than contacting sensors.

-

Reverse Mount Configuration: Designed for installations where traditional forward mounting is not possible, the reverse mount probe is flexible and adaptable to different machinery setups.

-

Wide Operating Temperature Range: It operates within a temperature range of -40°C to +85°C, making it suitable for a wide variety of environments, including extreme heat and cold.

-

Durable Construction: Made from stainless steel and Inconel, the 3300 XL Reverse Mount Probe is built to withstand harsh industrial environments and is resistant to corrosion, high temperatures, and mechanical stress.

-

IP67 Protection: The probe is rated IP67, meaning it is fully protected against dust and can withstand water immersion for short periods, ensuring reliable performance in tough industrial conditions.

Frequently Asked Questions (FAQs)

-

What is the measurement range of the 3300 XL Reverse Mount Probe?

The probe measures displacement from 0 to 11 mm, making it versatile for both small and large displacements. -

What type of output signal does this probe provide?

The probe outputs a 4-20 mA linear signal, commonly used in industrial applications for reliable data transmission to monitoring systems. -

How is the 3300 XL Reverse Mount Probe mounted?

The probe uses a reverse mount configuration, which allows for installation in situations where traditional forward mounting isn’t feasible. -

What is the power supply requirement for the 3300 XL probe?

The probe operates with a 24 V DC power supply, compatible with most industrial systems. -

What is the operating temperature range of this probe?

The probe operates effectively in environments with temperatures ranging from -40°C to +85°C. -

What is the weight of the 3300 XL Reverse Mount Probe?

The probe weighs 0.07 kg, making it lightweight and easy to install in compact spaces. -

What materials are used in the construction of the probe?

The probe is constructed from high-quality materials, including stainless steel and Inconel, ensuring durability in harsh industrial environments. -

What industries can benefit from the 3300 XL Reverse Mount Probe?

The probe is suitable for use in power generation, oil & gas, manufacturing, HVAC, aerospace, and other industries that require reliable machinery health monitoring. -

What environmental protection rating does the probe have?

The probe is rated IP67, meaning it is fully protected from dust and can withstand brief water immersion. -

What is the total length of the 3300 XL Reverse Mount Probe?

The probe has total length of 1 meter.

Related Models from the Bently Nevada 3300 XL Series

| Model | Measurement Range | Output Signal | Weight | Application |

|---|---|---|---|---|

| 330705-02-18-10-01-00 | 0 to 11 mm | 4-20 mA (Linear) | 0.30 kg | Shaft displacement, turbine monitoring |

| 330705-02-18-10-03-00 | 0 to 11 mm | 4-20 mA (Linear) | 0.31 kg | Compressors, pumps, motors |

| 330705-02-18-10-04-00 | 0 to 11 mm | 4-20 mA (Linear) | 0.32 kg | Oil & gas, rotating equipment |

| 330705-02-18-10-05-00 | 0 to 11 mm | 4-20 mA (Linear) | 0.33 kg | Manufacturing, conveyors, presses |

| 330705-02-18-10-06-00 | 0 to 11 mm | 4-20 mA (Linear) | 0.35 kg | HVAC systems, critical machinery |

| 330705-02-18-10-07-00 | 0 to 11 mm | 4-20 mA (Linear) | 0.34 kg | Aerospace, turbines, generators |

Popular Models from Bently Nevada

| Model | Measurement Range | Output Signal | Weight | Application |

|---|---|---|---|---|

| 3300 XL 5 mm Probe | 0 to 5 mm | 4-20 mA (Linear) | 0.2 kg | Vibration monitoring in bearings |

| 3500/42M Vibration Probe | 0 to 5 mm | 4-20 mA (Linear) | 0.45 kg | Industrial vibration monitoring |

| 3300/25 Proximity Probe | 0 to 25 mm | 4-20 mA (Linear) | 0.6 kg | Gas turbines, pumps, compressors |

| 330500-04-00 Velomitor | 0.2 to 2000 mm/s | 4-20 mA (Linear) | 0.35 kg | Vibration monitoring, machinery |

| 3500/53 Velocity Probe | 0.2 to 1500 mm/s | 4-20 mA (Linear) | 0.55 kg | Critical machinery, turbines, pumps |

| 330500-06-00 Velocity Probe | 0.2 to 1000 mm/s | 4-20 mA (Linear) | 0.45 kg | Compressors, machinery monitoring |

Excellent PLC

Excellent PLC