| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

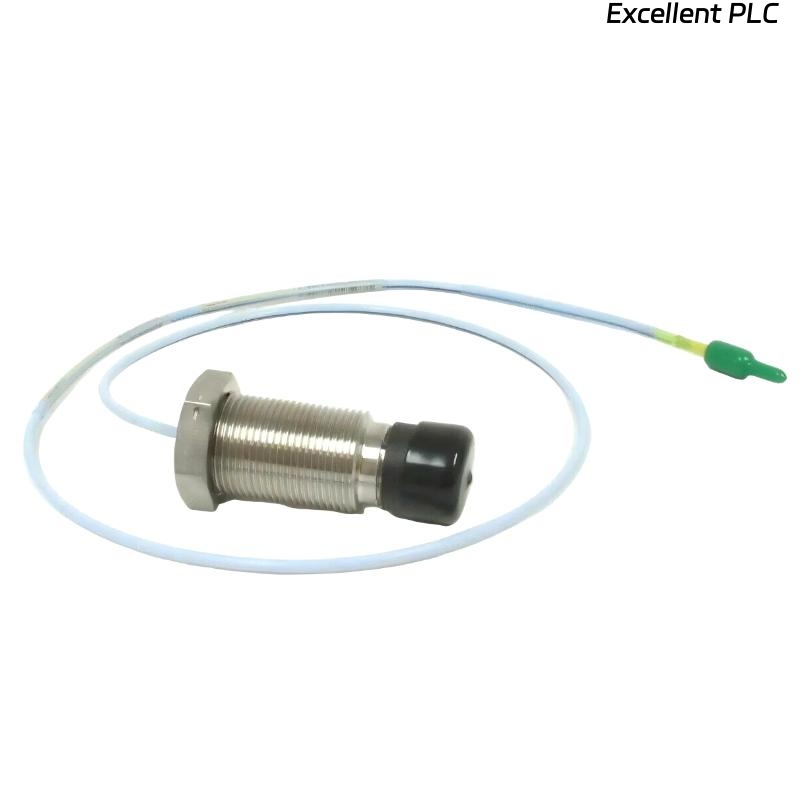

The Bently Nevada 330106-05-30-02-CN 3300 XL 8 mm Reverse Mount Probe is a high-performance, non-contact eddy current displacement sensor designed for continuous monitoring and protection of critical rotating equipment. Developed as part of the world-renowned Bently Nevada 3300 XL series, this probe provides exceptional accuracy, mechanical durability, and stability under harsh industrial conditions.

Engineered to meet the demanding standards of turbomachinery and rotating equipment monitoring, this reverse-mount probe enables secure installation from the back side of a mounting surface. This design effectively reduces the risk of oil contamination, mechanical damage, and installation difficulties common in confined spaces. It forms an integral part of Bently Nevada’s proximity measurement system, when paired with a 3300 XL Proximitor Sensor and extension cable, ensuring unmatched reliability and signal integrity.

The 330106-05-30-02-CN probe is extensively used across industries such as power generation, oil & gas, petrochemicals, and heavy machinery manufacturing, where precision vibration and position monitoring are essential to maintaining equipment health and operational safety.

Technical Specifications

| Parameter | Description |

|---|---|

| Model Number | 330106-05-30-02-CN |

| Series | 3300 XL 8 mm Reverse Mount Probe |

| Measurement Principle | Eddy current (non-contact displacement sensing) |

| Probe Tip Diameter | 8 mm |

| Nominal Linear Range | 2.0 mm (80 mils) |

| Sensitivity | 7.87 V/mm (200 mV/mil) |

| Frequency Range | DC to 10 kHz |

| Linearity Error | ±0.25% of full-scale |

| Temperature Coefficient | ≤ ±5% over full range |

| Operating Temperature Range | -35°C to +177°C |

| Storage Temperature Range | -55°C to +200°C |

| Probe Body Material | AISI 303 stainless steel |

| Mounting Configuration | Reverse-mount threaded connection |

| Mounting Thread | M10x1 or 3/8-24 UNF |

| Cable Type | Coaxial cable with PTFE insulation |

| Connector Type | ClickLoc™ quick-disconnect connector |

| Environmental Protection | IP67, oil and dust resistant |

| Electrical Isolation | Internally shielded to minimize noise |

| Vibration Limit | 196 m/s² (20 g), 0–2000 Hz |

| Shock Limit | 5000 m/s² (500 g) peak, 1 ms duration |

| Power Supply | Via 3300 XL Proximitor Sensor |

| Output Signal | DC voltage proportional to gap/displacement |

| Calibration Material | AISI 4140 steel |

| Compliance Standards | CE, RoHS |

| Total Length | 5.0 meters |

| Weight | 0.95 kg |

Product Applications

The Bently Nevada 330106-05-30-02-CN 8 mm Reverse Mount Probe is specifically engineered for high-value machinery monitoring systems where non-contact vibration and displacement measurements are essential for predictive maintenance. It is ideally suited for the following applications:

-

Turbomachinery – Monitoring shaft vibration and radial position to detect imbalance, rubs, and misalignment.

-

Compressors – Tracking bearing clearances and rotor movement to prevent mechanical failures.

-

Motors and Generators – Measuring shaft displacement and vibration for early fault detection.

-

Pumps and Fans – Monitoring shaft position and vibration for smooth operation.

-

Gearboxes – Ensuring gear mesh alignment and identifying wear or imbalance.

-

Petrochemical Equipment – Providing reliable performance under oil-laden or corrosive industrial conditions.

-

Refinery Machines – Detecting shaft instabilities and bearing wear before catastrophic failure.

The reverse-mount design offers superior protection from contamination and mechanical stress, making this probe particularly valuable in machinery with high vibration levels or limited installation space.

Product Advantages

The 330106-05-30-02-CN probe offers numerous advantages that make it one of the most reliable and accurate proximity probes in the market. It combines mechanical robustness, superior signal stability, and compatibility with existing monitoring systems.

-

Reverse-Mount Installation – Enables mounting from the rear of the machine housing, preventing oil ingress and improving accessibility.

-

Enhanced Signal Integrity – Uses advanced shielding to minimize electromagnetic interference.

-

Excellent Temperature Stability – Maintains consistent output across wide temperature variations.

-

High Mechanical Durability – Designed to withstand strong vibrations and shocks.

-

Factory Calibration – Each probe is individually matched with its Proximitor Sensor for maximum accuracy.

-

Corrosion and Oil Resistance – Stainless steel body and hermetic sealing for use in harsh industrial environments.

-

Reliable Performance in Harsh Conditions – Operates effectively in environments with oil, dust, and moisture.

-

Fully Compatible System Integration – Seamlessly integrates with Bently Nevada 3500 and 3300 monitoring systems.

-

Low Maintenance – Long operational lifespan without need for recalibration.

-

Global Industrial Standard – Trusted across industries for reliability, precision, and ease of installation.

FAQ

-

What measurement technology is used in the 330106-05-30-02-CN probe?

It operates based on the eddy current principle, measuring changes in the electromagnetic field to detect target displacement or vibration. -

Can the probe be used with any Bently Nevada Proximitor sensor?

It is specifically designed for use with the 3300 XL Proximitor Sensor and must be paired with matching cable lengths for accurate calibration. -

Is the reverse-mount probe interchangeable with a forward-mount version?

Mechanically, they differ in mounting configuration, but electrically they function similarly if correctly calibrated with the proper Proximitor sensor. -

How is electrical interference minimized in this probe?

The probe features an internal coaxial shield that isolates the measurement signal from electromagnetic noise. -

What materials can the probe measure displacement against?

It is calibrated for conductive ferromagnetic materials such as AISI 4140 steel, commonly used in shaft surfaces. -

Can this probe operate in oil-laden or high-humidity environments?

Yes, it has an IP67 environmental protection rating, ensuring resistance to oil, dust, and moisture. -

Does the probe require recalibration after installation?

No, each probe is factory-calibrated as part of a matched system, ensuring accurate performance without recalibration. -

What is the impact of temperature on probe sensitivity?

The temperature coefficient is controlled within ±5%, maintaining stable output across wide temperature variations. -

Can this probe handle strong vibration and shock conditions?

Yes, it withstands vibrations up to 20 g and shock levels up to 500 g, making it ideal for high-speed rotating machinery. -

What happens if a mismatched cable length is used with this probe?

Using an unmatched cable may alter the sensitivity and linearity, leading to measurement errors. Only factory-calibrated matched systems are recommended.

Related Models (Same or Similar Series)

| Model Number | Description | Cable Length | Weight |

|---|---|---|---|

| 330106-05-05-02-CN | 3300 XL 8 mm Reverse Mount Probe | 5 m | 0.95 kg |

| 330106-05-10-02-CN | 3300 XL 8 mm Reverse Mount Probe | 10 m | 0.95 kg |

| 330106-05-15-02-CN | 3300 XL 8 mm Reverse Mount Probe | 15 m | 0.95 kg |

| 330106-05-20-02-CN | 3300 XL 8 mm Reverse Mount Probe | 20 m | 0.95 kg |

| 330106-05-25-02-CN | 3300 XL 8 mm Reverse Mount Probe | 25 m | 0.95 kg |

| 330106-05-35-02-CN | 3300 XL 8 mm Reverse Mount Probe | 35 m | 0.95 kg |

Popular Models from the Same Brand (Bently Nevada)

| Model Number | Product Description | Type | Weight |

|---|---|---|---|

| 3300/12-01-20-01 | AC Power Supply Module | Power Supply | 1.00 kg |

| 3500/42M | Proximitor/Seismic Monitor | Monitoring Module | 0.90 kg |

| 3500/22M | Transient Data Interface | Data Module | 0.85 kg |

| 3500/33 | 16-Channel Relay Module | Relay Module | 0.95 kg |

| 330103-05-10-02-00 | 3300 XL 8 mm Proximity Probe | Proximity Probe | 0.32 kg |

| 330180-91-00 | 3300 XL Extension Cable | Extension Cable | 0.20 kg |

Excellent PLC

Excellent PLC