| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

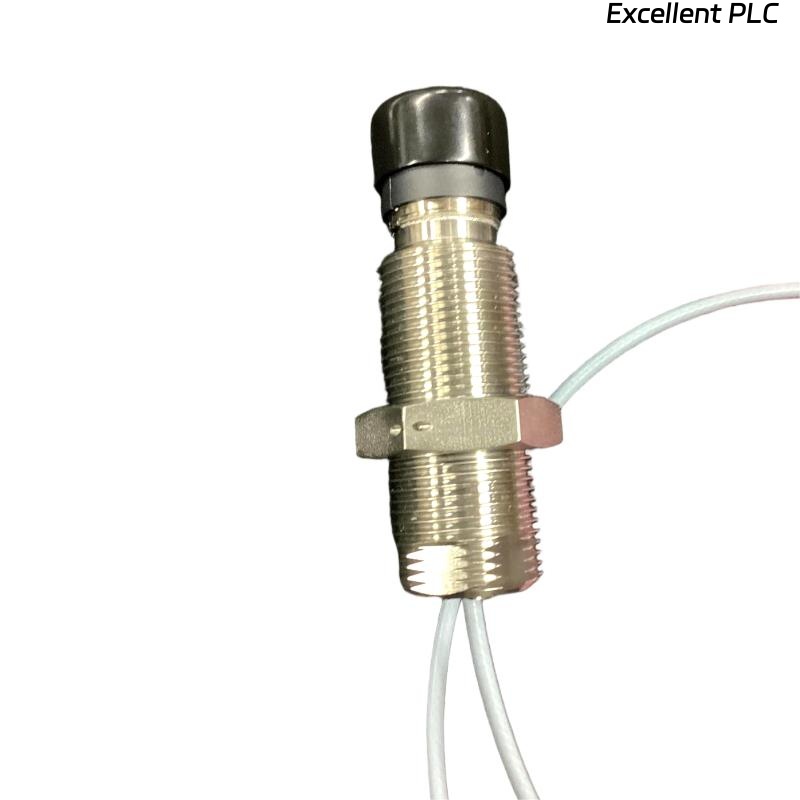

The Bently Nevada 330851-05-000-040-10-00-05 3300 XL 25 mm Proximity Probe is a high-precision sensor designed to monitor shaft displacement and vibration in rotating machinery. Part of the 3300 XL Series, this proximity probe offers accurate condition monitoring, helping to detect misalignment, imbalance, and bearing wear in critical equipment such as turbines, compressors, pumps, and motors.

With a total length of 1.0 meter, the probe is particularly suitable for installations where measurement points are located relatively close to the monitoring system, ensuring precise feedback on machinery displacement. Featuring a stainless steel housing, it is designed for use in harsh industrial environments, offering robust protection against corrosion and mechanical damage. With 25 mm sensing distance and high accuracy, the probe is essential for predictive maintenance and condition-based monitoring.

This probe plays a crucial role in preventive maintenance by helping operators identify early signs of machinery issues, which can significantly reduce unplanned downtime, repair costs, and extend equipment lifespan.

Product Specifications

| Parameter | Details |

|---|---|

| Model Number | 330851-05-000-040-10-00-05 |

| Type | Proximity Probe |

| Tip Diameter | 25 mm |

| Total Length | 1.0 meter |

| Weight | 0.23 kg |

| Sensing Distance | 25 mm |

| Output Type | 4-20 mA, Current Output |

| Frequency Response | Up to 20 kHz |

| Maximum Operating Temp | 125°C |

| Mounting Type | Threaded Mount |

| Housing Material | Stainless Steel |

| Accuracy | ±0.1 mm |

| Operating Temperature | -40°C to +125°C |

Product Applications

The 3300 XL 25 mm Proximity Probe is widely used in a variety of industries for condition-based monitoring and predictive maintenance of rotating machinery. Key applications include:

-

Rotating Equipment Monitoring: Primarily used for monitoring shaft displacement and vibration in turbines, compressors, motors, and pumps.

-

Predictive Maintenance: Helps detect early signs of wear, misalignment, imbalance, and bearing degradation, allowing for proactive maintenance actions to avoid unexpected failures.

-

Power Generation: Essential for monitoring turbines and generators in power plants to ensure smooth, continuous operation.

-

Oil & Gas Industry: Used in offshore platforms and refineries to monitor critical machinery, reducing the risk of unexpected breakdowns.

-

Mining & Heavy Industry: Critical in industries where large, heavy machinery is key to production, enabling continuous equipment monitoring to avoid costly interruptions.

-

Pump & Compressor Monitoring: Helps monitor centrifugal pumps and compressors, detecting signs of mechanical issues early to prevent system failure.

Product Advantages

-

Compact Design for Easy Installation: With a 1.0-meter length, the probe is suitable for installations in smaller systems where space is limited or for equipment that requires shorter-range measurements.

-

High Accuracy: Offering a ±0.1 mm accuracy, this probe provides precise readings, ensuring reliable feedback on machinery health.

-

Durable in Harsh Environments: The stainless steel housing protects the probe against corrosion and physical damage, ensuring durability even in tough industrial conditions.

-

Wide Temperature Range: The probe operates efficiently in temperatures ranging from -40°C to +125°C, making it versatile for use in various environments.

-

Flexible Integration: With its 4-20 mA current output, the probe integrates easily with most condition monitoring systems, allowing for seamless integration into existing setups.

-

High Frequency Response: The up to 20 kHz frequency response makes the probe suitable for monitoring high-speed machinery and detecting high-frequency vibrations.

-

Simple Mounting: The threaded mounting design simplifies installation, reducing both time and labor costs.

-

Preventive Maintenance: By providing real-time data on equipment condition, it supports preventive maintenance strategies, helping to minimize downtime and repair costs.

FAQ

Q1: What is the sensing distance of the 3300 XL 25 mm Proximity Probe?

The sensing distance is 25 mm, which is ideal for monitoring small displacements in rotating machinery.

Q2: What output does the 3300 XL proximity probe provide?

The probe provides a 4-20 mA current output, making it compatible with most industrial monitoring systems.

Q3: What is the frequency response of the 3300 XL proximity probe?

The probe has a frequency response of up to 20 kHz, allowing for monitoring of high-speed machinery.

Q4: What is the accuracy of the 3300 XL proximity probe?

The probe offers ±0.1 mm accuracy, ensuring precise and reliable displacement measurements.

Q5: How is the 3300 XL proximity probe mounted?

The probe features a threaded mounting design, making it easy to install and integrate with other equipment.

Q6: Can the 3300 XL probe operate in extreme temperatures?

Yes, the probe operates in a wide temperature range from -40°C to +125°C, suitable for a variety of industrial environments.

Q7: What industries use the 3300 XL 25 mm Proximity Probe?

The probe is ideal for industries like power generation, oil & gas, mining, and manufacturing, where rotating machinery is prevalent.

Q8: Can the 3300 XL proximity probe monitor high-speed equipment?

Yes, the probe’s high-frequency response makes it ideal for monitoring high-speed rotating machinery like turbines and compressors.

Q9: What is the total length of the 3300 XL proximity probe?

The probe has a total length of 1.0 meter, designed for use in applications where space or installation distances are more compact.

Q10: What material is the housing of the 3300 XL probe made from?

The probe features a stainless steel housing, providing durability and protection against corrosion.

Recommended Related Models

| Model | Description |

|---|---|

| 330851-05-000-030-10-00-05 | A 30 mm proximity probe for larger displacement measurements. |

| 330851-05-000-050-10-00-05 | A 50 mm proximity probe designed for high precision measurements in larger equipment. |

| 330853-01-020-10-01-00 | A high-frequency proximity probe for precise monitoring of high-speed machinery. |

| 330852-01-010-20-00-00 | A 100 mm probe for more complex machinery, providing detailed condition feedback. |

| 330855-01-040-10-01-00 | A multi-purpose probe ideal for turbines and larger machines requiring more detailed measurements. |

| 330858-02-030-10-01-00 | A dual-output probe that provides both displacement and vibration measurements. |

Popular Models in Similar Categories

| Model | Description |

|---|---|

| 330500-01-10-10 | A vibration transducer used for advanced machinery health monitoring. |

| 330300-01-00 | A dual-axis vibration sensor for multi-directional monitoring of rotating machinery. |

| 330400-01-20-00 | A machine protection system that integrates both vibration and displacement monitoring. |

| 330850-01-20-00 | A shaft displacement sensor for high-accuracy condition monitoring. |

| 330865-01-10-00 | A temperature sensor for integration with other monitoring systems to track machinery health. |

| 330880-01-10-00 | A flexible sensor designed for use in difficult-to-reach installations in rotating machinery. |

Excellent PLC

Excellent PLC