| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

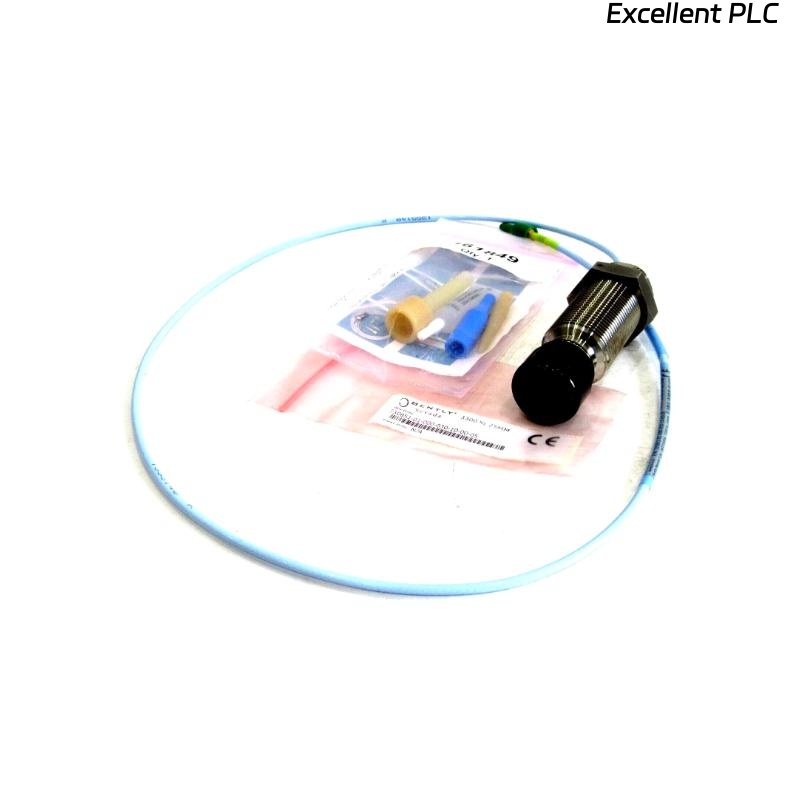

The Bently Nevada 330851-08-000-026-10-01-CN is a high-precision 25mm proximity probe from the 3300 XL series. Specifically designed for machinery condition monitoring, this probe provides reliable measurements of shaft displacement, vibration, and other key parameters of rotating machinery. The 3300 XL series is known for its accuracy and robustness, and this model continues that legacy, offering exceptional performance in harsh industrial environments.

The probe is widely used for applications such as vibration monitoring, predictive maintenance, and machinery protection. It integrates seamlessly into Bently Nevada’s extensive suite of monitoring systems, enabling the detection of faults like misalignment, imbalance, and bearing wear before they lead to catastrophic failures. Made from high-quality stainless steel, this model is durable and resistant to corrosion, ensuring long-term reliability even in the most challenging conditions.

Product Specifications

| Specification | Value |

|---|---|

| Model | Bently Nevada 330851-08-000-026-10-01-CN |

| Probe Type | Proximity Probe (25 mm) |

| Probe Size | 25 mm diameter |

| Total Length | 1.0 meter |

| Weight | 0.33 kg |

| Material | Stainless Steel |

| Temperature Range | -40°C to +120°C |

| Mounting Type | Surface Mount |

| Signal Type | 4-20mA Output |

| Operating Voltage | 10-30 VDC |

| Measurement Range | 0-25 mm |

| Accuracy | ±0.05 mm |

Applications

The 3300 XL 25mm Proximity Probe is highly effective in a variety of industrial applications, particularly those involving rotating machinery:

-

Vibration Monitoring: The probe measures the displacement of rotating shafts, helping detect early signs of vibration issues such as imbalance or misalignment that could lead to damage or downtime.

-

Condition Monitoring: Used in continuous monitoring systems to assess the health of machinery, the probe helps detect anomalies such as bearing wear, shaft displacement, or other critical faults.

-

Predictive Maintenance: By providing real-time data, the probe enables predictive maintenance strategies, allowing for maintenance to be scheduled before a failure occurs, saving time and money.

-

Machinery Protection: As part of a machinery protection system, this probe ensures that equipment operates within safe limits, reducing the risk of catastrophic failure.

-

Rotating Equipment Monitoring: It is used for monitoring turbines, motors, pumps, and compressors, where accurate displacement measurement is essential for early fault detection.

-

Power Generation & Oil & Gas: Essential in industries like oil & gas, power generation, and mining, where rotating equipment is crucial to operations and uptime is critical.

Advantages

-

High Accuracy: The 3300 XL 25mm Proximity Probe offers ±0.05 mm accuracy, allowing for precise measurements of shaft displacement and vibration.

-

Wide Temperature Range: The probe operates effectively in temperatures from -40°C to +120°C, making it ideal for use in extreme conditions.

-

Corrosion-Resistant Construction: Made from durable stainless steel, the probe is resistant to corrosion and wear, ensuring long-lasting reliability.

-

Real-Time Data: It provides real-time monitoring of machinery condition, enabling early fault detection and reducing the risk of unplanned downtime.

-

Flexible Integration: The 4-20 mA output signal makes it easy to integrate into existing monitoring systems, allowing for streamlined data collection and analysis.

-

Cost-Effective Maintenance: By detecting faults early, this probe helps reduce maintenance costs, extend the lifespan of machinery, and minimize unplanned shutdowns.

-

Durability: The 3300 XL 25mm Proximity Probe is built to withstand harsh industrial environments, ensuring it continues to provide accurate data in demanding conditions.

FAQ

1. How does the 3300 XL proximity probe detect displacement?

The 3300 XL 25mm Proximity Probe uses inductive sensing technology to detect changes in the magnetic field as the probe moves relative to the rotating shaft. These changes are translated into displacement measurements, providing data on the health of the machinery.

2. What is the significance of the 4-20mA output signal?

The 4-20mA output is a standard signal used in industrial control and monitoring systems. It allows the probe to easily integrate into existing machinery monitoring systems and transmit real-time data to control panels or monitoring software.

3. Can the probe be used for high-precision applications?

Yes, the 3300 XL 25mm Proximity Probe offers a high level of accuracy (±0.05 mm), making it suitable for high-precision applications where small deviations in machinery behavior need to be detected.

4. What types of faults can this probe detect?

The 3300 XL 25mm Proximity Probe can detect a variety of faults, including misalignment, imbalance, bearing wear, shaft displacement, and other mechanical issues that could affect the performance of rotating equipment.

5. How is the probe mounted on machinery?

The 3300 XL 25mm Proximity Probe is designed for surface mounting on rotating machinery, such as shafts or turbine blades, for accurate displacement measurement.

6. How does this probe help with predictive maintenance?

By providing continuous, real-time data, the probe allows operators to monitor the condition of machinery and identify potential faults before they lead to breakdowns, enabling predictive maintenance and reducing downtime.

7. What is the operating voltage of the 3300 XL proximity probe?

The 3300 XL 25mm Proximity Probe operates within a voltage range of 10-30 VDC, which is compatible with most industrial monitoring systems.

8. What makes the probe suitable for harsh environments?

The 3300 XL 25mm Proximity Probe is constructed from stainless steel, which makes it durable and resistant to corrosion and wear, even in harsh industrial environments with high temperatures, humidity, or exposure to chemicals.

9. Can the probe be used for machinery protection in critical applications?

Yes, the 3300 XL 25mm Proximity Probe is widely used in machinery protection systems to monitor key parameters and ensure equipment operates within safe limits, preventing catastrophic failures.

10. How does the probe contribute to reducing maintenance costs?

By identifying faults early, the 3300 XL 25mm Proximity Probe allows for proactive maintenance scheduling, which can prevent major breakdowns and reduce repair costs associated with unplanned downtime.

Related Product Recommendations

Here are some related models from the Bently Nevada 3300 XL series and other Bently Nevada models:

| Model | Description |

|---|---|

| 330851-04-000-020-10-00-05 | A similar 25mm proximity probe suitable for general-purpose use. |

| 330851-04-000-080-10-00-05 | Features enhanced durability for high-vibration environments. |

| 330851-04-000-070-10-00-05 | Designed for larger machinery with an extended measurement range. |

| 330851-04-000-015-10-00-05 | A more compact version, ideal for smaller equipment or tight spaces. |

| 330851-05-000-040-50-01-05 | A high-accuracy model designed for complex systems with longer cables. |

| 330851-06-000-070-50-00-05 | Offers additional protection against extreme environmental conditions. |

Popular Bently Nevada Models

| Model | Description |

|---|---|

| 3500-33-01-00-00-00-01 | A multi-channel vibration monitoring system designed for critical machinery. |

| 3500-42-02-01-00-00-01 | System for real-time monitoring of vibration, temperature, and pressure. |

| 3500-22-01-01-00-00-01 | Vibration transducer for detecting displacement and velocity. |

| 3500-91-01-00-00-01 | A signal conditioning system designed to optimize sensor data. |

| 3500-72-01-00-00-01 | Machinery protection relay for critical equipment monitoring. |

| 3500-60-01-00-00-01 | Comprehensive system for monitoring critical equipment conditions in large facilities. |

Excellent PLC

Excellent PLC