| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

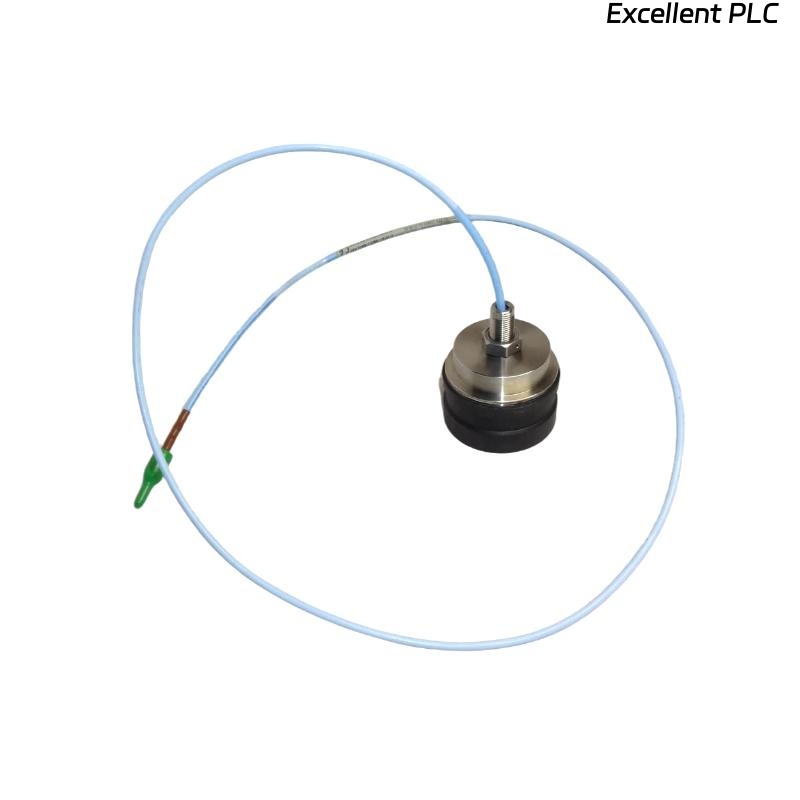

The Bently Nevada 330876-03-10-01-00 3300 XL 50 mm Proximity Probe is a high-precision, non-contact sensor designed for monitoring shaft displacement and vibration in critical industrial machinery. Part of the 3300 XL series, this probe delivers accurate, high-fidelity measurements essential for condition monitoring and machinery protection systems. With a 50 mm probe tip, it is optimized for larger machinery applications such as turbines, compressors, and generators. The probe converts mechanical displacement into an electrical signal compatible with Bently Nevada Proximitor® sensors and monitoring systems, providing reliable early detection of misalignment, imbalance, or mechanical degradation.

Product Parameters

| Parameter | Specification |

|---|---|

| Model Number | 330876-03-10-01-00 |

| Probe Type | 3300 XL 50 mm Proximity Probe |

| Linear Range | 5–50 mm (depending on installation) |

| Sensitivity | 7.87 mV/µm nominal |

| Frequency Response | 0 Hz – 10 kHz (±3 dB) |

| Operating Temperature | –35 °C to +177 °C |

| Storage Temperature | –40 °C to +177 °C |

| Pressure Rating | Up to 2000 psi (137 bar) |

| Insulation Resistance | >10 MΩ @ 500 VDC |

| Cable Type | Factory-integrated, armored |

| Total Cable Length | 1.0 meter |

| Shipping Weight | 3 kg |

Applications

-

Large Turbines – Shaft displacement and vibration monitoring for steam, gas, and hydro turbines.

-

Compressors – Continuous monitoring of high-speed compressors to prevent bearing damage or misalignment.

-

Electric Generators – Rotor position tracking for generator protection and performance optimization.

-

Industrial Pumps – Shaft vibration monitoring in critical process applications.

-

Petrochemical Plants – Condition monitoring in high-pressure, high-temperature process equipment.

-

Heavy Industrial Equipment – Detects imbalance, rubs, or misalignment in large rotating machinery.

Advantages

-

High Accuracy – Provides precise linear measurement over a wide range with minimal thermal drift.

-

API 670 Compliance – Meets international standards for machinery protection and vibration monitoring.

-

Robust Design – Stainless steel construction and armored cable ensure durability in harsh industrial environments.

-

Wide Operating Range – Operates reliably under extreme temperatures, pressure, and vibration conditions.

-

Seamless System Integration – Fully compatible with 3300 XL Proximitor® sensors and monitoring systems.

-

Non-Contact Measurement – Reduces wear and maintenance while providing reliable continuous monitoring.

-

Easy Installation – Designed for rapid deployment in large machinery applications.

FAQ

-

What target material provides the most accurate measurement?

AISI 4140 or similar carbon steel is recommended for calibration and best accuracy. -

How is electromagnetic interference minimized?

The probe uses a coaxial design with grounded shielding to reduce external electrical noise. -

Can the probe operate in high-vibration environments?

Yes, it is designed to maintain stable measurements even under severe vibration. -

What is the typical output impedance of the probe system?

Approximately 50 Ω when connected to the specified Proximitor sensor. -

How does the probe compensate for temperature changes?

Internal materials and factory calibration minimize thermal drift across the operating temperature range. -

Is this probe compatible with older Bently Nevada drivers?

It is recommended to use with 3300 XL or 3500 series Proximitor drivers for full performance. -

What is the recommended gap voltage for optimal linearity?

Typically around –10 VDC at mid-gap position. -

How does cable length affect signal quality?

The probe is calibrated for a total system length; any modification requires recalibration. -

What protection does the probe provide against moisture ingress?

The assembly meets IP67 sealing when installed with proper hardware. -

What is the maximum static pressure rating at the probe tip?

The probe tip can withstand pressures up to 2000 psi (137 bar).

Recommended Related Models

| Model | Description |

|---|---|

| 330876-03-10-01-01 | 3300 XL 50 mm Proximity Probe, alternate configuration |

| 330877-03-10-01-00 | 3300 XL 50 mm Proximity Probe, high-temperature variant |

| 330878-03-10-01-00 | 3300 XL 50 mm Reverse-Mount Probe |

| 330879-03-10-01-00 | 3300 XL 50 mm Dual-Purpose Probe |

| 330880-03-10-01-00 | 3300 XL 50 mm Long-Range Probe |

| 330881-03-10-01-00 | 3300 XL 50 mm NSv Narrow Side-View Probe |

Popular Bently Nevada Models

| Model | Application |

|---|---|

| 3500/22M | Transient Data Interface Module |

| 3500/42M | Proximitor/Seismic Monitoring Module |

| 3500/50E | Keyphasor Module |

| 3500/60 | Temperature Monitoring Module |

| 3701/55 | Reciprocating Compressor Monitor |

| 330500 | Velomitor Velocity Transducer |

Excellent PLC

Excellent PLC