| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

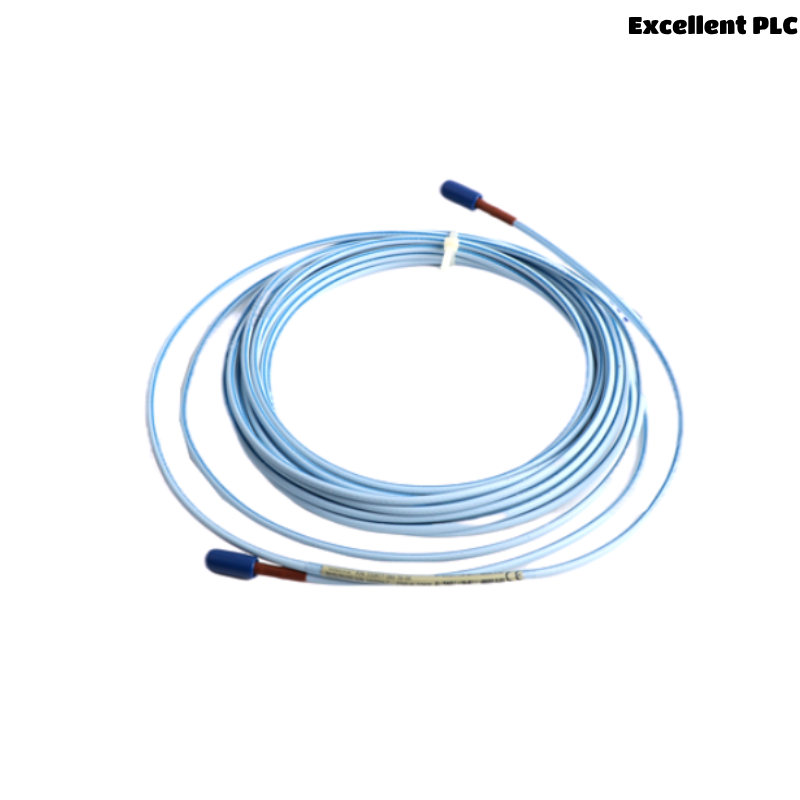

The Bently Nevada 330877-080-37-00 is a rugged, high-precision 50 mm proximitor probe designed for use in the 3300 XL series machinery protection system. This probe is engineered to deliver accurate and reliable shaft displacement and vibration measurements for critical rotating equipment, helping prevent failures and reduce downtime.

Its large 50 mm diameter tip ensures stable sensing even in harsh and noisy industrial environments, where vibration and shaft position monitoring are essential for safe operation. With a robust stainless steel body and advanced eddy current technology, the probe offers long-lasting durability and dependable performance.

The 330877-080-37-00 probe integrates seamlessly with the 3300 XL monitoring system, providing real-time data essential for predictive maintenance and machinery health management.

Product Specifications

| Parameter | Description |

|---|---|

| Model Number | 330877-080-37-00 |

| Series | 3300 XL |

| Probe Diameter | 50 mm |

| Tip Style | Flat Face |

| Sensing Range | 12.7 mm (0.5 inch) |

| Operating Temperature | -40°C to +120°C |

| Storage Temperature | -55°C to +150°C |

| Total Length | 8 meters |

| Connector Type | MIL-C-26482 Military-grade Connector |

| Weight | 0.36 kg |

| Probe Body Material | Stainless Steel |

| Protection Rating | IP67 |

| Output Signal | AC signal proportional to target gap |

| Mounting Style | Threaded mounting |

Applications

This proximitor probe is ideal for a wide variety of heavy industrial applications that demand reliable shaft position and vibration monitoring:

-

Power Generation Turbines – Monitoring shaft displacement in steam and gas turbines

-

Large Compressors – Ensuring rotor position stability and early fault detection

-

Hydroelectric Generators – Vibration and shaft movement measurement to protect bearings

-

Industrial Pumps and Fans – Detection of misalignment and mechanical wear

-

Metal Processing Equipment – Monitoring shaft behavior under heavy operational stresses

-

Petrochemical Plants – Critical rotating machinery condition monitoring

Key Advantages

-

Robust 50 mm Tip: Offers stable and consistent readings for large machinery.

-

Durable Build: Stainless steel housing resists corrosion, dust, and moisture.

-

High Precision: Eddy current sensing provides fast and accurate feedback.

-

Wide Temperature Range: Suitable for environments from -40°C to +120°C.

-

IP67 Protection: Well-protected against dust ingress and water exposure.

-

Seamless Compatibility: Easily integrates with 3300 XL monitoring equipment.

Frequently Asked Questions (FAQ)

-

What kind of machinery is this probe best suited for?

It is designed for large rotating equipment like turbines, compressors, and generators where accurate shaft monitoring is critical. -

Can this probe operate in wet or dusty environments?

Yes, with an IP67 rating, it can withstand harsh industrial conditions including dust and water exposure. -

How long is the cable supplied with the probe?

The standard total length is 8 meters, though custom lengths can be ordered. -

Does this probe require special connectors?

It uses MIL-C-26482 military-grade connectors to ensure a secure and reliable connection. -

What is the typical sensing range of the probe?

The probe has a sensing range of 12.7 mm (0.5 inch), ideal for stable measurements on large shafts. -

Is the probe compatible with older 3300 series systems?

It is designed for the 3300 XL series; compatibility with older systems should be verified case-by-case. -

How durable is the probe’s housing?

Constructed from stainless steel, it is highly resistant to corrosion, physical damage, and environmental wear. -

What kind of maintenance does this probe require?

Regular visual inspections and connector checks are recommended to ensure optimal performance. -

Can the probe be used in hazardous or explosive environments?

Use in hazardous areas requires proper certification and installation practices; consult with Bently Nevada experts. -

How much does the probe weigh?

The probe weighs 0.36 kg.

Related or Similar Models

| Model Number | Probe Diameter | Sensing Range | Connector Type | Typical Application |

|---|---|---|---|---|

| 330876-02-10-00-00 | 50 mm | 12.7 mm | MIL-C-26482 | Large shaft monitoring |

| 330877-02-10-00-00 | 50 mm | 12.7 mm | MIL-C-26482 | Heavy-duty industrial use |

| 330878-02-15-00-00 | 75 mm | 19.05 mm | MIL-C-26482 | Extra-large industrial shafts |

| 330870-02-10-00-00 | 50 mm | 12.7 mm | MIL-C-26482 | High precision large probes |

| 330850-X0-06 | 30 mm | 7.62 mm | MIL-C-26482 | Medium industrial applications |

| 330853-02-10-00-00 | 50 mm | 12.7 mm | MIL-C-26482 | Compressor shaft monitoring |

Popular Bently Nevada Models

| Model Number | Type | Application | Output | Dimensions (mm) | Weight |

|---|---|---|---|---|---|

| 3300 XL Monitor | Vibration Monitor | Machinery condition monitoring | Analog/Digital | 230 × 175 × 90 | 3.5 kg |

| 3500 Series Proximitor | Proximity Sensor | Shaft displacement sensing | AC Signal | Various | 0.15–0.3 kg |

| 1701 Vibration Transmitter | Overall Vibration | Vibration level measurement | 4–20 mA | 120 × 80 × 60 | 0.6 kg |

| 2300 Portable Monitor | Field Vibration Monitor | Portable diagnostics | Digital | Handheld device | 1.1 kg |

| 1331 Eddy Current Probe | Proximity Probe | Shaft vibration sensing | AC Signal | Various | 0.2 kg |

| 3300 XL System Processor | Signal Processing Unit | Data acquisition & processing | Digital | 150 × 120 × 70 | 1.2 kg |

Excellent PLC

Excellent PLC