| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

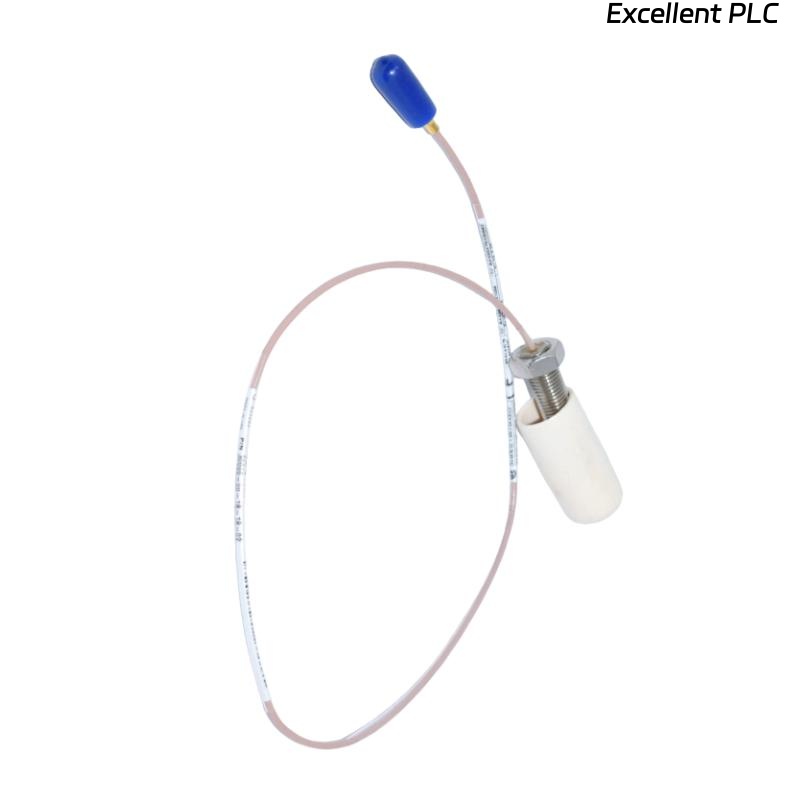

The Bently Nevada 330901-00-12-05-02 3300 NSv Proximity Probe is a precision non-contact sensor specifically engineered for shaft vibration and axial position measurements in small and medium-sized industrial machines. As part of the renowned Bently Nevada 3300 NSv (Narrow Signal Version) series, it delivers highly accurate displacement and vibration monitoring where space constraints or small shaft diameters make standard probes impractical.

This probe operates on the eddy current principle, generating a magnetic field to measure the exact distance between the probe tip and the rotating shaft surface. It forms a complete proximity measurement system when used with a 3300 NSv Proximitor Sensor and a coaxial extension cable. The system provides a linear output proportional to shaft movement or vibration, enabling accurate machinery diagnostics and protection.

Designed for harsh industrial environments, the 330901-00-12-05-02 offers excellent immunity to temperature fluctuations, electromagnetic interference, and oil contamination. It complies fully with API 670 standards, ensuring compatibility with global vibration and condition monitoring systems.

Technical Specifications

| Parameter | Specification |

|---|---|

| Model Number | 330901-00-12-05-02 |

| Product Type | Proximity Probe (NSv Series) |

| System Type | Non-contact eddy current displacement sensor |

| Operating Principle | Eddy current measurement |

| Compatible Driver | 3300 NSv Proximitor Sensor (Part No. 330930 series) |

| Nominal Linear Range | 1.0 mm (40 mils) |

| Linear Range (Typical) | 0.25–1.25 mm |

| Probe Tip Material | Polyphenylene sulfide (PPS), non-conductive |

| Shaft Material Compatibility | 4140 steel or equivalent ferromagnetic alloys |

| System Output | -200 mV/μm (typical) |

| Sensitivity Tolerance | ±6% |

| Frequency Response | 0 to 10 kHz (–3 dB) |

| Maximum Vibration | 200 m/s² (20 g) peak |

| Operating Temperature | –35°C to +177°C |

| Storage Temperature | –50°C to +200°C |

| Probe Thread Size | M8 × 1.0 |

| Cable Type | Coaxial, armored, factory molded |

| Total Length | 0.5 meter |

| Connector Type | Miniature coaxial connector (female) |

| Overall System Accuracy | ±5% typical with calibrated matching system |

| Environmental Protection | Hermetically sealed, oil and moisture resistant |

| Mounting Method | Threaded mount with locknut |

| Compliance Standards | API 670, CE, IEC 60068, ISO 10816 |

| Weight | 0.15 kg |

| Insulation Resistance | > 10 MΩ @ 500 VDC |

| Cable Jacket Material | Fluoropolymer (Teflon-coated) |

| Probe Body Material | Stainless steel (AISI 304) |

Applications

The Bently Nevada 330901-00-12-05-02 NSv Probe is primarily used for shaft vibration, position, and thrust monitoring in compact machinery or installations with limited mounting space. It ensures precise real-time measurement and integrates easily into vibration monitoring and protection systems for industrial rotating equipment.

Typical applications include:

-

Small Gas and Steam Turbines: Provides reliable rotor position and vibration data for protection systems.

-

Compressors and Pumps: Used to detect shaft vibration and misalignment in high-speed rotating equipment.

-

Gearboxes and Motors: Monitors dynamic shaft behavior and mechanical looseness.

-

Fans and Blowers: Detects imbalance or bearing wear in smaller rotating machinery.

-

Industrial Test Benches: Used in laboratory setups for dynamic balancing and shaft vibration testing.

-

Aerospace and Marine Systems: Suitable for compact turbine assemblies or auxiliary rotating units where space is limited.

Advantages

-

Compact Form Factor: Ideal for small machinery and tight installation spaces.

-

High Precision Measurement: Provides accurate shaft displacement and vibration readings with linear performance.

-

Compliant with API 670 Standards: Ensures global compatibility and adherence to vibration protection norms.

-

Excellent Environmental Resistance: Operates effectively in oil, moisture, and high-temperature environments.

-

Robust Mechanical Design: Stainless steel housing offers superior durability and corrosion resistance.

-

High Electromagnetic Immunity: Shielded coaxial cable minimizes interference in electrically noisy environments.

-

Extended Temperature Capability: Operates over a wide range, suitable for harsh industrial applications.

-

Easy Integration: Directly compatible with Bently Nevada 3300 NSv Proximitor systems and monitoring racks.

-

Stable Calibration: Factory-calibrated for reliable performance across long operational periods.

-

Low Maintenance Requirement: Hermetically sealed design reduces downtime and ensures long-term accuracy.

FAQ

-

What type of sensing technology is used in the 330901-00-12-05-02 probe?

It uses eddy current sensing technology, generating a magnetic field to measure the distance between the probe tip and a conductive target surface. -

Which Proximitor module should be paired with this probe?

It is designed to work specifically with the Bently Nevada 3300 NSv Proximitor Sensor (330930 series) to ensure accurate system calibration. -

Can this probe be used for both vibration and position monitoring?

Yes, it provides both dynamic (vibration) and static (shaft position) measurements within its linear range. -

Is the probe compatible with standard 3300 XL systems?

It is optimized for NSv (Narrow Signal Version) systems and may not be fully interchangeable with standard 3300 XL components. -

What is the nominal system output for this probe?

The system typically outputs –200 mV per micrometer of shaft movement when used with the correct Proximitor module. -

How does temperature affect the measurement accuracy?

The system is temperature-compensated, maintaining accuracy within ±5% across its specified operating range. -

Can the probe operate in oil-lubricated environments?

Yes, it is fully sealed and oil-resistant, making it suitable for turbine and compressor bearing housings. -

What kind of target materials provide the most accurate readings?

The probe is calibrated for 4140 steel, and readings may vary slightly if used with other metallic materials. -

How is electrical noise minimized in this probe?

The coaxial cable and shielded design reduce electromagnetic interference, ensuring signal stability. -

Can the probe be used in high-vibration environments?

Yes. It can withstand up to 20 g peak vibration without degradation in accuracy or structural integrity.

Related Models (Same Series or Similar Configuration)

| Model Number | Description | Cable Length | Output Sensitivity | Key Feature |

|---|---|---|---|---|

| 330901-00-12-10-02 | NSv Proximity Probe | 1.0 m | –200 mV/μm | Standard length probe |

| 330901-00-08-05-02 | NSv Proximity Probe | 0.5 m | –200 mV/μm | Short cable version |

| 330901-00-18-10-02 | NSv Proximity Probe | 1.8 m | –200 mV/μm | Extended reach for remote sensors |

| 330930-065-01-05 | NSv Proximitor Sensor | – | – | Drives probe and provides linear output |

| 330130-040-00 | 3300 XL Probe | 4.0 m | –200 mV/μm | Standard XL series probe |

| 330171-00-90-10-02 | Extension Cable | 9.0 m | – | Armored coaxial extension cable |

Popular Models (Same Brand – Bently Nevada)

| Model Number | Product Type | Function | Typical Application |

|---|---|---|---|

| 3300 XL 5 mm Probe | Proximity Probe | Shaft vibration monitoring | Turbines, compressors |

| 330104-00-20-10-02 | Extension Cable | Signal transmission | XL probe systems |

| 3500/22M | Communication Module | Data interface for 3500 rack | Machinery protection systems |

| 3500/42M | Vibration Monitor | Measures X-Y vibration channels | Turbine vibration analysis |

| 3500/92 | Display Module | Local display for 3500 rack | Condition monitoring |

| 330505-02-12-10-02 | Proximitor Sensor | Probe driver | Integrates NSv probes |

Excellent PLC

Excellent PLC