| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

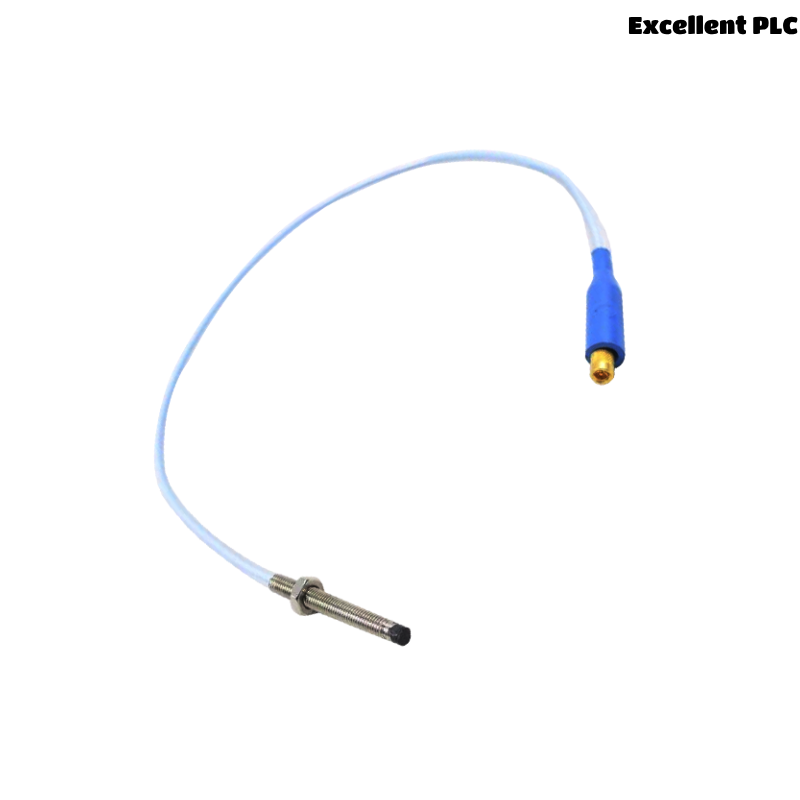

Bently Nevada 330901-00-40-05-02-05 Product Overview

The Bently Nevada 330901-00-40-05-02-05 is a high-performance vibration monitoring system designed to offer real-time diagnostics and predictive maintenance solutions for critical industrial machinery. This product is part of the renowned Bently Nevada 3300 series, which is widely used in industries like oil & gas, power generation, and manufacturing to prevent equipment failure, reduce downtime, and improve operational efficiency.

This system provides precise vibration measurements, allowing operators to monitor the health of machines and identify potential issues before they lead to costly failures. The 330901-00-40-05-02-05 is equipped with advanced sensors, signal processing technology, and user-friendly interfaces, making it suitable for a wide range of rotating equipment such as turbines, motors, and compressors.

Product Advantages

-

Advanced Diagnostics: The Bently Nevada 330901-00-40-05-02-05 offers advanced vibration diagnostics and machine protection, improving predictive maintenance strategies and reducing downtime.

-

Reliability: Known for its robust design and reliability in harsh industrial environments, the system provides high accuracy and longevity.

-

Real-time Data: Provides real-time feedback on equipment performance, helping operators take quick corrective actions.

-

Comprehensive Monitoring: It allows for comprehensive monitoring of vibration, temperature, and other critical parameters, enhancing the overall health management of machinery.

-

User-friendly Interface: Easy-to-read outputs and intuitive control make the system simple to operate and integrate into existing monitoring systems.

-

Cost-efficient: Helps to reduce operational costs by minimizing unscheduled maintenance and preventing catastrophic machinery failures.

Product Specifications

| Specification | Details |

|---|---|

| Model | 330901-00-40-05-02-05 |

| Weight | 0.128kg |

| Cable length | 0.5 m |

| Power Supply | 24 VDC (Nominal) |

| Operating Temperature | -40°C to +85°C |

| Input Voltage Range | 20-30 VDC |

| Output Type | Analog, Digital, and Communication outputs |

| Communication Protocols | Modbus, Profibus, Ethernet |

| Protection Class | IP67 (Dust and waterproof) |

Applications

The Bently Nevada 330901-00-40-05-02-05 is suitable for a wide range of applications across various industries:

-

Oil & Gas: To monitor rotating equipment in drilling, refining, and processing facilities.

-

Power Generation: Vibration monitoring of turbines, generators, and other critical machinery to ensure smooth operations.

-

Manufacturing: Vibration and condition monitoring for motors, pumps, and compressors used in production lines.

-

Industrial Equipment: Ensures the operational efficiency of high-speed rotating machinery and protects against unexpected failures.

-

Aerospace: For monitoring turbine engines and other essential machinery in aviation systems.

Product Advantages

-

Predictive Maintenance: It aids in forecasting potential machine failures, reducing the likelihood of unscheduled downtime.

-

Comprehensive Monitoring: Monitors all critical vibration parameters, ensuring complete equipment health management.

-

Flexibility and Scalability: Can be integrated with various types of rotating equipment, making it a versatile choice for different industries.

-

Durable Construction: Built to endure extreme environmental conditions, ensuring longevity and minimal maintenance.

-

Cost Savings: Helps to avoid costly repairs and maintenance by catching faults early and addressing them before they lead to failure.

-

Highly Accurate: Provides precise, real-time vibration data for efficient machine monitoring.

Frequently Asked Questions (FAQs)

-

What types of equipment can the Bently Nevada 330901-00-40-05-02-05 monitor?

-

This system can monitor various rotating equipment such as turbines, motors, pumps, compressors, and other critical machinery.

-

-

How does the Bently Nevada 330901-00-40-05-02-05 detect faults?

-

It uses vibration analysis to detect irregularities in the machine’s operation, which helps to identify early-stage faults like imbalance, misalignment, or bearing wear.

-

-

Can the 330901-00-40-05-02-05 be integrated with other systems?

-

Yes, the system supports multiple communication protocols like Modbus, Profibus, and Ethernet for easy integration with existing machinery and monitoring systems.

-

-

What industries benefit from using this product?

-

Oil & Gas, Power Generation, Manufacturing, Aerospace, and other industrial sectors with critical rotating machinery.

-

-

Is the system durable enough for harsh environments?

-

Yes, the Bently Nevada 330901-00-40-05-02-05 is built to withstand tough industrial environments, with a protection class of IP67, making it resistant to dust and water.

-

-

What is the typical lifespan of the product?

-

The system is designed for long-lasting performance, with proper maintenance and care, the product can function for several years.

-

-

How do I install the 330901-00-40-05-02-05?

-

Installation involves mounting the system to the equipment, wiring it according to the provided instructions, and configuring the communication settings.

-

-

Can I monitor multiple pieces of equipment with a single unit?

-

Yes, the system can be configured to monitor multiple assets across your facility, streamlining maintenance and monitoring efforts.

-

-

Does it offer real-time alerts for maintenance?

-

Yes, the system provides real-time data and alerts based on pre-set thresholds to inform operators about potential issues before they escalate.

-

-

What is the warranty for the Bently Nevada 330901-00-40-05-02-05?

-

The product typically comes with a standard 1-year warranty.

Recommended Models (Same Series or Related)

| Model | Description | Weight | Dimensions (L x W x H) |

|---|---|---|---|

| Bently Nevada 330104-00 | Vibration transmitter for industrial equipment | 1.2 kg | 150 mm x 110 mm x 50 mm |

| Bently Nevada 330503-00 | Proximity sensor for rotor position monitoring | 1.0 kg | 140 mm x 100 mm x 45 mm |

| Bently Nevada 330702-00 | Vibration sensor for pumps and compressors | 1.3 kg | 180 mm x 120 mm x 60 mm |

| Bently Nevada 330803-00 | Dynamic measurement for rotating machinery | 1.4 kg | 160 mm x 110 mm x 55 mm |

| Bently Nevada 330902-00 | Comprehensive vibration monitoring and diagnostics | 1.6 kg | 170 mm x 120 mm x 65 mm |

| Bently Nevada 330004-00 | Condition monitoring system for motors | 1.1 kg | 155 mm x 115 mm x 50 mm |

Popular Bently Nevada Models

| Model | Description | Weight | Dimensions (L x W x H) | Voltage |

|---|---|---|---|---|

| Bently Nevada 330104-00 | Vibration monitoring for motors and machinery | 1.2 kg | 150 mm x 110 mm x 50 mm | 24 VDC |

| Bently Nevada 330503-00 | Vibration sensor for rotating equipment | 1.0 kg | 140 mm x 100 mm x 45 mm | 24 VDC |

| Bently Nevada 330702-00 | Vibration and temperature sensor for machinery | 1.3 kg | 180 mm x 120 mm x 60 mm | 24 VDC |

| Bently Nevada 330803-00 | Advanced condition monitoring for turbines | 1.4 kg | 160 mm x 110 mm x 55 mm | 24 VDC |

| Bently Nevada 330902-00 | Vibration and proximity monitoring systems | 1.6 kg | 170 mm x 120 mm x 65 mm | 24 VDC |

| Bently Nevada 330004-00 | Proximity vibration sensor for heavy machinery | 1.1 kg | 155 mm x 115 mm x 50 mm | 24 VDC |

| Bently Nevada 350104-00 | Vibration system for power generation turbines | 1.8 kg | 180 mm x 130 mm x 70 mm | 24 VDC |

| Bently Nevada 350503-00 | High-frequency vibration measurement | 1.2 kg | 160 mm x 120 mm x 60 mm | 24 VDC |

Excellent PLC

Excellent PLC