| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

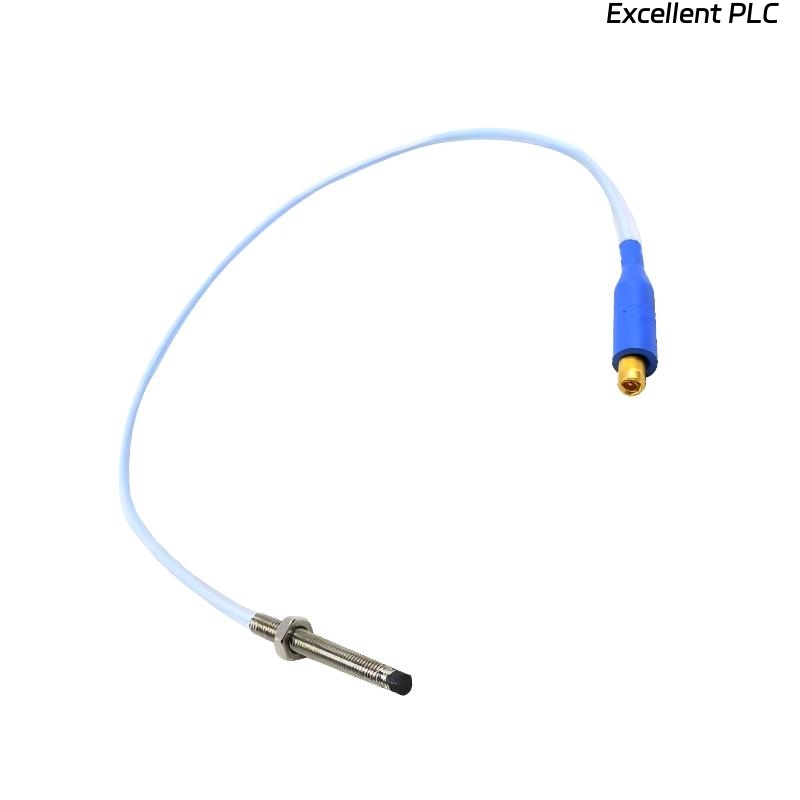

The Bently Nevada 330901-00-90-10-10-02-05 3300 NSv Proximity Probe is a precision-engineered non-contact displacement sensor designed for the accurate measurement of shaft vibration, position, and phase reference in compact rotating machinery. Belonging to the 3300 NSv (Narrow Signal Version) family, this probe is optimized for applications where the installation space is limited, such as small turbines, compressors, gearboxes, and pumps.

This probe functions based on the eddy current principle, generating an electromagnetic field that interacts with the conductive shaft surface. Any movement of the shaft alters this field, allowing the probe to output a precise voltage proportional to the displacement. When paired with a Bently Nevada 3300 NSv Proximitor Sensor and appropriate extension cable, it forms a complete measurement chain that meets API 670 standards for machinery protection and condition monitoring.

The 330901-00-90-10-10-02-05 model is known for its exceptional linearity, wide temperature tolerance, and strong immunity to environmental contaminants, ensuring stable and repeatable performance even under severe operating conditions such as oil-lubricated housings or high electromagnetic interference zones.

Technical Specifications

| Parameter | Specification |

|---|---|

| Model Number | 330901-00-90-10-10-02-05 |

| Series | Bently Nevada 3300 NSv (Narrow Signal Version) |

| Product Type | Non-contact Eddy Current Proximity Probe |

| Operating Principle | Eddy current-based displacement measurement |

| Compatible Driver | 3300 NSv Proximitor Sensor (e.g., 330930 series) |

| Nominal Linear Range | 1.0 mm (40 mils) |

| Total Measurement Range | 0.25 to 1.25 mm |

| System Sensitivity | –200 mV/μm ±6% |

| Output Signal Type | Voltage (proportional to displacement) |

| Frequency Response | 0 – 10 kHz (–3 dB) |

| Linearity Deviation | ±1% of full scale typical |

| Probe Tip Material | Polyphenylene sulfide (PPS), non-conductive |

| Body Material | Stainless Steel (AISI 304) |

| Target Material (Calibration) | AISI 4140 steel or equivalent ferromagnetic material |

| Mounting Thread Size | M8 × 1.0 |

| Cable Type | Coaxial, factory molded with armor protection |

| Total Length | 1.0 meter |

| Connector Type | Miniature coaxial connector (female) |

| Operating Temperature Range | –35°C to +177°C |

| Storage Temperature Range | –50°C to +200°C |

| Maximum Vibration | 20 g (200 m/s²) peak |

| Insulation Resistance | >10 MΩ @ 500 VDC |

| Environmental Protection | Hermetically sealed, oil and moisture resistant |

| Compliance Standards | API 670, CE, IEC 60068, ISO 10816 |

| Weight | 0.15 kg |

| Cable Jacket Material | Fluoropolymer (Teflon) |

| Typical Output Noise | <10 mV rms |

| Calibration Tolerance | ±5% typical across system configuration |

Applications

The Bently Nevada 330901-00-90-10-10-02-05 NSv Probe is designed for precise shaft displacement and vibration measurements in compact machinery and systems where conventional probes cannot be installed due to space limitations. Its robust performance and linear response make it ideal for monitoring both dynamic and static shaft conditions.

Typical application areas include:

-

Small Steam and Gas Turbines – For real-time rotor vibration and axial position monitoring.

-

Compressors and Pumps – Detects mechanical looseness, unbalance, and misalignment.

-

Gearboxes and Electric Motors – Provides accurate displacement data for fault diagnosis and predictive maintenance.

-

Industrial Fans and Blowers – Monitors bearing wear, rotor instability, and imbalance.

-

Power Generation Units – Ensures continuous protection of rotating components in auxiliary systems.

-

Marine and Aerospace Machinery – Used in compact turbine assemblies and secondary rotating drives.

Advantages

-

Compact and Space-Saving Design: Optimized for confined installation environments where larger probes cannot fit.

-

High Measurement Accuracy: Delivers stable, repeatable output with minimal drift over time.

-

Complies with API 670 Standards: Ensures full compatibility with international vibration and protection systems.

-

Robust Environmental Resistance: Performs reliably in oil-laden and high-temperature conditions.

-

Enhanced EMI Protection: Coaxial shielded cable provides strong immunity against electrical interference.

-

Durable Stainless Steel Construction: Offers excellent corrosion resistance and mechanical strength.

-

Temperature-Stable Calibration: Maintains performance accuracy across a wide thermal range.

-

Fully Sealed Assembly: Hermetically sealed design prevents ingress of contaminants and moisture.

-

Low Maintenance Operation: Long-term stability reduces recalibration and maintenance requirements.

-

Seamless Integration: Works directly with Bently Nevada 3300 NSv Proximitor modules and standard monitoring systems.

FAQ

-

What measurement principle does the 330901-00-90-10-10-02-05 probe use?

It operates using the eddy current principle, detecting changes in magnetic field due to shaft movement. -

Which Proximitor module is compatible with this probe?

The probe is designed to work with the Bently Nevada 3300 NSv Proximitor Sensor (330930 series). -

Can this probe measure both vibration and shaft position?

Yes. It provides accurate dynamic (vibration) and static (position) measurements simultaneously. -

What is the output sensitivity of the system?

The standard output sensitivity is –200 mV/μm, calibrated at 4140 steel target material. -

Is this probe suitable for operation in oil-lubricated environments?

Yes, it is hermetically sealed and resistant to oil, making it suitable for bearing housings and turbines. -

How does temperature variation affect the probe’s performance?

It maintains consistent accuracy due to temperature compensation built into the probe and Proximitor combination. -

Can this probe be used in high vibration intensity environments?

Yes, it withstands up to 20 g peak vibration without loss of measurement accuracy. -

What type of target materials provide the best calibration accuracy?

The probe is factory-calibrated for AISI 4140 steel, ensuring maximum linearity and repeatability. -

How is signal integrity maintained in electrically noisy environments?

The coaxial cable and shielding design protect the signal from electromagnetic interference. -

Can it be integrated into existing Bently Nevada monitoring systems?

Yes, it is fully compatible with Bently Nevada 3300 and 3500 system architectures using appropriate signal conditioning modules.

Related Models (Same Series or Similar Configuration)

| Model Number | Description | Cable Length | Sensitivity | Key Feature |

|---|---|---|---|---|

| 330901-00-12-05-02 | NSv Proximity Probe | 0.5 m | –200 mV/μm | Compact version for small machines |

| 330901-00-18-10-02 | NSv Proximity Probe | 1.8 m | –200 mV/μm | Extended length for remote applications |

| 330901-00-10-05-02 | NSv Proximity Probe | 1.0 m | –200 mV/μm | General purpose standard probe |

| 330930-065-01-05 | NSv Proximitor Sensor | – | – | Compatible driver for NSv probe systems |

| 330171-00-90-10-02 | Extension Cable | 9.0 m | – | Armored coaxial signal extension |

| 330130-040-00 | 3300 XL Probe | 4.0 m | –200 mV/μm | Standard version for large shafts |

Popular Models (Same Brand – Bently Nevada)

| Model Number | Product Type | Function | Typical Application |

|---|---|---|---|

| 3500/42M | Vibration Monitor | Monitors dual X-Y channels | Turbines, compressors |

| 3500/92 | Display Module | Visual display of system parameters | Machinery protection systems |

| 3500/22M | Communication Module | Rack data interface | 3500 Series monitoring rack |

| 330505-02-12-10-02 | Proximitor Sensor | Probe driver for NSv probes | Shaft vibration monitoring |

| 3300 XL 5 mm Probe | Proximity Probe | Shaft displacement monitoring | Standard industrial machinery |

| 330104-00-20-10-02 | Extension Cable | Signal transmission | 3300 XL series connection cable |

Excellent PLC

Excellent PLC