| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

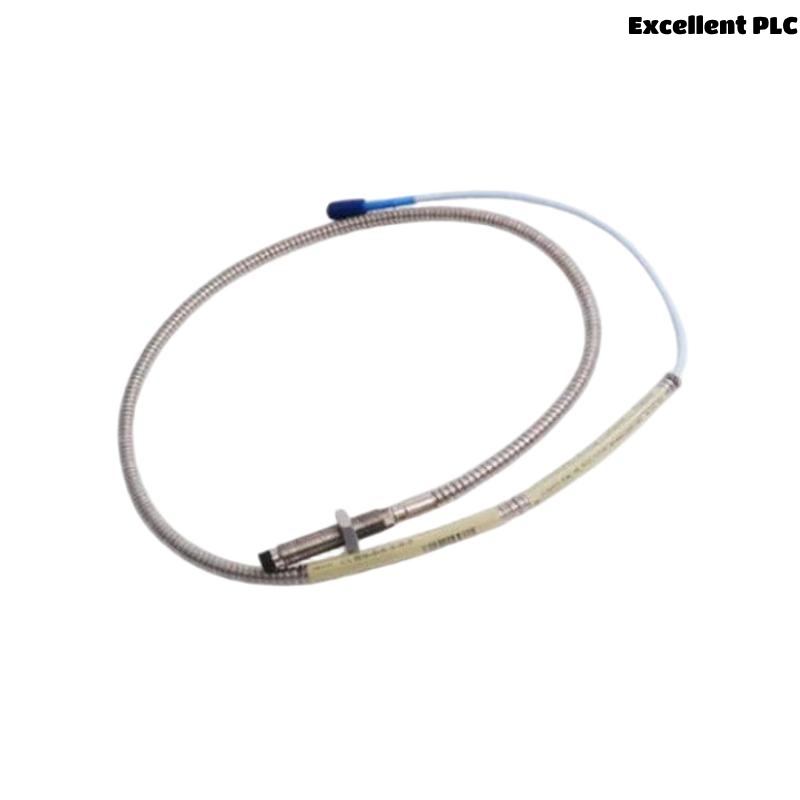

The Bently Nevada 330905-00-03-10-02-00 is a high-precision 3300 NSv proximity probe designed for continuous condition monitoring of rotating machinery. Engineered for durability and accuracy, it provides essential shaft vibration and displacement measurements in a variety of industrial applications. This model uses metric dimensions and is tailored to meet global industrial standards, ensuring compatibility with many machinery systems worldwide.

Featuring a total length of 1 meter and a shipping weight of approximately 2 kg, this probe is constructed to withstand demanding operational environments while delivering reliable, real-time data. It is commonly used in industries such as power generation, oil and gas, manufacturing, mining, and chemical processing, where early detection of mechanical faults is critical.

Product Parameters

| Parameter | Specification |

|---|---|

| Model | 3300 NSv Proximity Probe (Metric) |

| Part Number | 330905-00-03-10-02-00 |

| Total Length | 1 meter |

| Shipping Weight | 2 kg |

| Tip Diameter | 5 mm |

| Sensing Range | ±2.0 mm |

| Frequency Response | DC to 10 kHz |

| Operating Temperature | -40°C to +120°C |

| Mounting Style | Threaded Mount |

| Vibration Resistance | 10 g peak (0–2000 Hz) |

| Shock Resistance | 200 g for 11 ms pulse |

Product Applications

The 330905-00-03-10-02-00 proximity probe is widely used for real-time monitoring of rotating machinery, enabling predictive maintenance and minimizing downtime. Typical applications include:

-

Power Generation

Monitoring turbines, generators, and other critical rotating equipment to detect imbalance, misalignment, and bearing wear. -

Oil and Gas Industry

Installed on pumps, compressors, and motors in refineries and offshore rigs for continuous condition monitoring. -

Mining

Provides early warnings on crushers, conveyor drives, and grinding mills operating under harsh conditions. -

Manufacturing

Ensures reliable operation of motors, gearboxes, and pumps in various manufacturing processes. -

Chemical Processing

Monitors agitators, mixers, and pumps to maintain safe and efficient plant operation. -

Water and Wastewater Treatment

Tracks the condition of pumps and motors vital to treatment facilities.

Product Advantages

-

Precision Measurement

Offers a sensing range of ±2.0 mm, providing accurate shaft displacement data. -

Robust Construction

Designed to endure extreme temperatures (-40°C to +120°C) and harsh industrial environments. -

Metric Dimensions

Tailored for global compatibility with metric machinery and installation standards. -

Optimal Cable Length

The 1-meter cable length supports flexible installation without signal degradation. -

Threaded Mount

Ensures secure and vibration-resistant mounting on machinery. -

Wide Frequency Response

Monitors vibration signals from DC to 10 kHz, suitable for a range of rotating speeds. -

High Shock and Vibration Resistance

Can withstand shocks of up to 200 g and vibrations up to 10 g peak. -

Lightweight Yet Durable

Despite its sturdy build reflected in the 2 kg shipping weight, the probe is easy to handle. -

Long Service Life

Engineered for reliability and minimal maintenance over long operational periods. -

Seamless Integration

Compatible with Bently Nevada’s 3300 and 3500 series protection and monitoring systems.

Frequently Asked Questions (FAQ)

-

Q: What is the total length of this probe?

A: The total length is 1 meter. -

Q: How much does the probe weigh?

A: The shipping weight is approximately 2 kg. -

Q: What is the sensing range of the probe?

A: It has a sensing range of ±2.0 mm. -

Q: What frequency range can it measure?

A: The probe detects vibration frequencies from DC up to 10 kHz. -

Q: What temperature range can it operate in?

A: It operates reliably between -40°C and +120°C. -

Q: What mounting style does the probe use?

A: It uses a threaded mount for secure installation. -

Q: Is the probe suitable for high vibration and shock environments?

A: Yes, it withstands vibration peaks up to 10 g and shocks up to 200 g. -

Q: Which industries use this proximity probe?

A: Power generation, oil and gas, mining, manufacturing, chemical, and water treatment sectors. -

Q: How does this probe help reduce downtime?

A: By providing early detection of mechanical faults, enabling timely maintenance. -

Q: Is this probe compatible with other Bently Nevada equipment?

A: Yes, it integrates seamlessly with 3300 and 3500 series monitoring systems.

Recommended Models (Same Series or Related)

| Model | Cable Length (m) | Weight | Key Features |

|---|---|---|---|

| 330902-00-40-10-02-00 | 1.0 | 0.82 kg | Extended cable, robust design |

| 330902-00-30-05-02-05 | 0.5 | 2.0 kg | Compact cable, heavy-duty |

| 330902-00-12-10-02-05 | 1.0 | 0.82 kg | Metric dimensions |

| 330903-00-30-05-02-05 | 0.5 | 2.2 kg | High temperature resistant |

| 330901-00-40-10-02-00 | 1.0 | 0.80 kg | Alternative mounting style |

| 330900-00-40-10-02-00 | 1.2 | 0.88 kg | Enhanced shock resistance |

Popular Models (Same Brand)

| Model | Description | Length | Connector Type | Application |

|---|---|---|---|---|

| 330904-02-20-05-01-00 | Extension cable, shielded, 0.5 m | 0.5 meter | Coaxial | Sensor extension in compact installations |

| 330904-04-14-05-02-00 | Extension cable, shielded, 0.5 m, rugged design | 0.5 meter | Coaxial | Industrial vibration monitoring |

| 330904-05-14-05-02-00 | Extension cable, shielded, 0.5 m, high flex | 0.5 meter | Coaxial | Dynamic machinery sensor connections |

| 330904-02-20-10-01-00 | Extension cable, shielded, 1.0 m | 1.0 meter | Coaxial | General sensor cable for harsh environments |

| 330904-04-14-10-02-00 | Extension cable, shielded, 1.0 m, rugged version | 1.0 meter | Coaxial | Heavy-duty vibration monitoring |

| 330904-05-14-10-02-00 | Extension cable, shielded, 1.0 m, high flex | 1.0 meter | Coaxial | Flexible sensor cable for rotating machinery |

Excellent PLC

Excellent PLC