| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

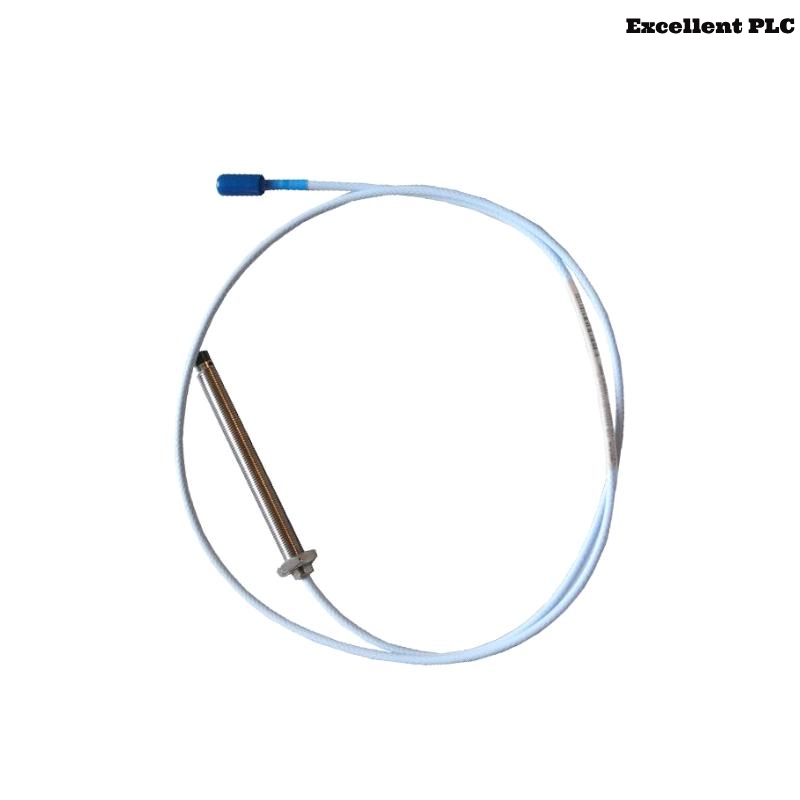

The Bently Nevada 330905-00-10-10-02 is a high-precision proximity probe from the 3300 NSv series, designed for non-contact measurement of vibration and position in industrial machinery. Utilizing eddy current technology, it provides accurate and reliable data essential for condition monitoring and machinery protection systems.

Product Specifications

| Parameter | Details |

| Model Number | 330905-00-10-10-02 |

| Series | 3300 NSv |

| Probe Tip Diameter | 5 mm |

| Thread Size | M10 x 1 |

| Overall Case Length | 100 mm |

| Cable Length | 1.0 meter |

| Connector Type | Miniature coaxial ClickLoc |

| Operating Temperature Range | -34°C to +177°C (-30°F to +351°F) |

| Storage Temperature Range | -51°C to +177°C (-60°F to +351°F) |

| Relative Humidity | Less than 3% change in Average Scale Factor (ASF) when tested per IEC 68-2-66 |

| Weight | 0.15 kg |

| Compliance | CE, RoHS (depending on system use) |

Product Applications

-

Rotating Machinery Monitoring: Ideal for turbines, compressors, motors, and pumps.

-

Power Generation: Suitable for monitoring steam and gas turbines in power plants.

-

Oil & Gas Industry: Effective in upstream, midstream, and downstream equipment health monitoring.

-

Petrochemical Plants: Monitors critical rotating assets in refineries and chemical processing facilities.

-

Marine and Aerospace: Applied in propulsion and auxiliary systems for condition monitoring.

-

Heavy Industry: Utilized in cement, mining, and steel industries for machinery protection.

Product Advantages

-

High Signal Integrity: Ensures minimal signal degradation over extended distances.

-

Robust Construction: Designed to withstand high temperatures and mechanical stress.

-

Environmental Resistance: Offers superior protection against moisture and contaminants.

-

EMI/RFI Protection: Provides excellent shielding against electromagnetic interference.

-

Easy Integration: Compatible with existing 3300 NSv monitoring systems.

-

Long-Term Reliability: Built for continuous industrial use with a long service life.

-

Secure Connections: Ensures stable and reliable connections.

-

Simplified Maintenance: Pre-calibrated for easy installation and replacement.

Recent News Titles Related to Product & Series

-

Bently Nevada Enhances 3300 NSv Series with Advanced Monitoring Capabilities

-

New Proximity Probe Designs Improve Reliability in Harsh Environments

-

Bently Nevada’s 3300 NSv Series Gains Popularity in Power Generation Sector

-

Innovations in Proximity Transducer Systems Lead to Improved Machinery Monitoring

-

Bently Nevada Releases Updated Specifications for 3300 NSv Proximity Probes

-

Industry Leaders Adopt Bently Nevada’s 3300 NSv Series for Critical Applications

Frequently Asked Questions (FAQ)

1: Is the 330905-00-10-10-02 probe suitable for use in machines with limited installation space?

Yes. The NSv (Narrow Side View) design of this model was specifically developed for tight-clearance installations such as small-frame turbines, gearboxes, or compact compressors. The probe’s compact body and shorter linear range are tailored for confined environments.

2: How far can I extend the probe cable without compromising signal integrity?

This model is designed for fixed cable lengths (e.g., 1.0 m as in this version). If longer distances are needed, use an appropriate extension cable in combination with a matching Proximitor sensor. Exceeding recommended lengths without proper impedance matching may lead to signal attenuation or phase shift.

3: What is the recommended gap (target distance) setting during installation?

The optimal initial gap between the probe tip and the target (typically a rotating shaft) is around 1.0 mm, but this may vary slightly based on the system calibration. It should fall within the linear measurement range of the sensor (generally ±0.5 mm from the mid-gap).

4: Can this probe be used to monitor axial thrust position in addition to radial vibration?

Yes, the 330905 series can be used for both radial vibration and axial position measurements, depending on installation. For axial thrust, ensure precise alignment and calibration, as any angular misalignment can introduce significant errors.

5: What kind of material surfaces can this probe accurately monitor?

The probe is calibrated for conductive metallic targets, most commonly 4140 steel or similar materials. If you’re working with a different material (e.g., stainless steel, titanium), a custom calibration may be required to maintain accuracy.

6: How should the cable be routed to minimize interference and mechanical wear?

Always route the cable away from high-voltage sources, sharp edges, and areas with high vibration. Use shielded conduit when necessary and avoid tight bends. The minimum bend radius is approximately 25 mm to preserve cable integrity.

7: What is the environmental sealing rating of this probe? Can it be used outdoors?

The 330905-00-10-10-02 probe is rated for IP65 environments, which means it is dust-tight and resistant to water spray. For outdoor or washdown environments, additional protective measures like sealed enclosures or flexible boots are recommended.

8: Is this probe compatible with all Bently Nevada Proximitor sensors?

It is compatible specifically with the 3300 NSv Proximitor sensor. Using it with a different series (such as 3300 XL or 7200) may lead to incorrect readings due to differences in scaling and probe characteristics.

9: What are common signs of probe failure or degradation over time?

Common symptoms include erratic signal readings, persistent zero output, increased noise in vibration data, or a drift in the baseline position measurement. Periodic inspection and comparing signal baselines help in early detection.

10: How frequently should the probe be recalibrated or verified in a critical machinery setup?

While factory calibration is stable over long periods, it’s good practice to verify probe performance annually in critical systems or during scheduled outages. This ensures measurement accuracy and early detection of any degradation or alignment shifts.

Related Models from the Same Series or Product Line

| Model Number | Description | Cable Length | Thread Size | Notes |

| 330905-00-05-10-02 | 3300 NSv Proximity Probe | 0.5 m | M10 x 1 | Shorter probe, ideal for compact machinery |

| 330905-00-07-10-02 | 3300 NSv Proximity Probe | 0.7 m | M10 x 1 | For medium-range installations |

| 330905-00-15-10-02 | 3300 NSv Proximity Probe | 1.5 m | M10 x 1 | Longer reach for larger equipment |

| 330930-065-01-05 | 3300 XL Proximitor Sensor Cable | 6.5 m | N/A | Compatible cable for Proximitor sensors |

| 330980-50-05 | 3300 XL NSv Proximitor Sensor | N/A | N/A | Sensor component to pair with NSv probes |

| 330130-045-00-00 | 3300 XL 8 mm Proximity Probe | 4.5 m | 3/8-24 UNF | Alternative with different tip size/thread |

Popular Models from the Same Brand (Bently Nevada)

| Model Number | Description | Application | Notes |

| 3500/22M | Transient Data Interface Module | Vibration/Condition Monitoring | Part of the 3500 series monitoring system |

| 3500/42M | Proximitor/Seismic Monitor | Machinery Protection | Four-channel module for vibration inputs |

| 3300 XL 8 mm (330130) | Proximity Probe | General Industrial Use | Most commonly used standard probe |

| 330104-00-10-10-02-00 | 3300 XL Proximity Probe | OEM Machinery Monitoring | Similar in function but with larger tip |

| 330180-91-00 | Extension Cable | Extension with ClickLoc connectors | For extended installations with reliability |

| 330500-02-00 | Proximitor Sensor Module | For proximity measurements | DIN rail mount, compact sensor interface |

Excellent PLC

Excellent PLC