| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

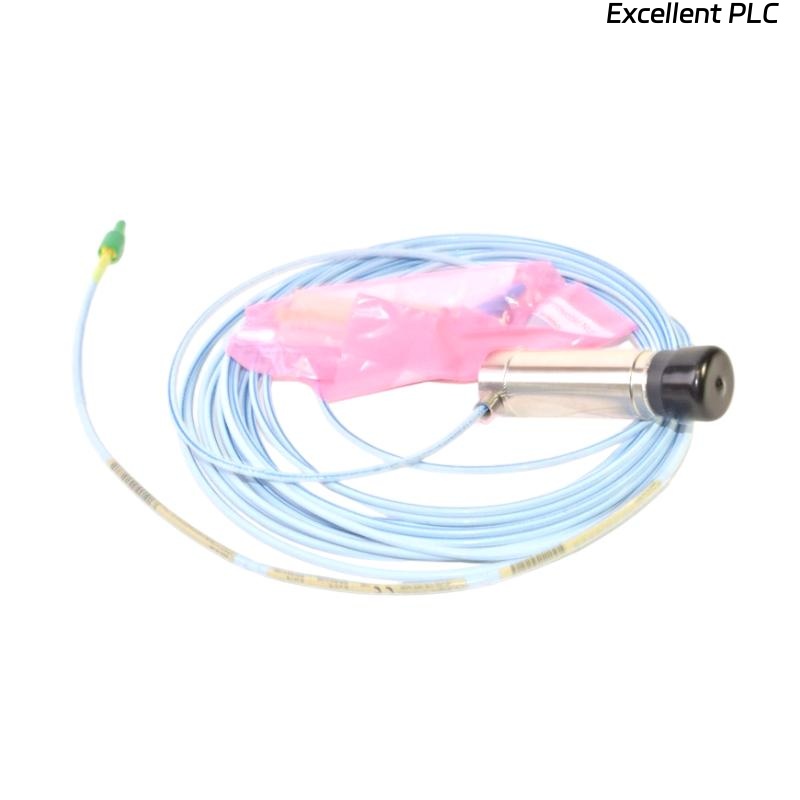

The Bently Nevada 330905-00-17-50-02-CN is a high-precision proximity sensor from the 3300 NSv series. This sensor is specifically designed for non-contact measurement of vibration and position in rotating machinery. With its advanced technology, it provides accurate data without the mechanical wear associated with traditional contact-based sensors. The 3300 NSv proximity sensor is ideal for use in industrial environments, where reliable monitoring of critical equipment such as turbines, compressors, motors, and pumps is essential for ensuring operational safety and efficiency.

The 3300 NSv sensor is built to offer exceptional performance, even in challenging conditions. It is commonly used for predictive maintenance and machinery health monitoring, allowing early detection of potential failures and preventing costly unplanned downtime. Its robust construction and high reliability make it a key component in various sectors, including power generation, petrochemical, and manufacturing.

Product Specifications

Below are the detailed specifications for the Bently Nevada 330905-00-17-50-02-CN proximity sensor:

| Parameter | Value |

|---|---|

| Brand | Bently Nevada |

| Model | 330905-00-17-50-02-CN |

| Type | 3300 NSv Proximity Sensor |

| Total Length | 5.0 meters |

| Weight | 0.15 kg |

| Measuring Range | ±6.35 mm |

| Output | Analog 4-20 mA, 0-10 VDC |

| Temperature Range | -40°C to 85°C |

| Operating Voltage | 18 to 30 VDC |

| Signal Type | Differential, Linear Analog Signal |

| Frequency Response | 5 kHz to 500 kHz |

| Housing Material | Stainless Steel |

Applications

The Bently Nevada 330905-00-17-50-02-CN proximity sensor is ideal for a wide range of applications in industrial machinery. Its non-contact measurement capabilities make it suitable for harsh environments where direct contact sensors would be impractical or could cause wear and tear. Here are the key applications:

-

Turbines: Used to monitor the vibration and position of turbine rotors, ensuring safe and efficient operation by detecting imbalance or misalignment early.

-

Motors: For monitoring motor shaft positions and vibration, the sensor helps in identifying potential issues like misalignment or bearing wear that could lead to failure.

-

Compressors: Used to track the movement and vibration of compressor shafts, preventing performance degradation and extending equipment life.

-

Pumps and Fans: Helps in monitoring large industrial pumps and fans, detecting any misalignment or vibrations that could result in mechanical failure.

-

Rotating Machinery: Ideal for monitoring rotating machinery in various industries, including power generation, petrochemical, and manufacturing, to ensure smooth and reliable operations.

Advantages

-

Non-Contact Measurement: By using advanced non-contact technology, the sensor eliminates physical wear, making it more durable and extending its operational life compared to traditional contact-based sensors.

-

High Precision and Reliability: It provides highly accurate measurements, which are crucial for the early detection of faults and ensuring continuous machine operation.

-

Wide Temperature Range: The sensor operates across a broad temperature range from -40°C to 85°C, making it suitable for use in extreme environmental conditions.

-

Durability: Constructed with stainless steel, the sensor is robust and can withstand harsh industrial environments, including chemical exposure, high humidity, and mechanical stress.

-

Easy Integration: It can be easily integrated into existing monitoring systems, including those from Bently Nevada and other third-party systems, making it a versatile choice for predictive maintenance applications.

-

Cost-Effectiveness: The sensor helps reduce operational costs by allowing for early identification of potential issues, enabling corrective actions before equipment failure occurs.

FAQ

-

What is the purpose of the 3300 NSv proximity sensor?

The 3300 NSv proximity sensor is used to measure the position and vibration of rotating machinery, providing critical data for predictive maintenance and fault detection. -

How does the 3300 NSv sensor differ from traditional proximity sensors?

The 3300 NSv uses non-contact measurement technology, offering greater accuracy and durability without the physical wear associated with traditional sensors. -

What kind of output signals does this sensor provide?

The sensor provides two types of analog output signals: 4-20 mA and 0-10 VDC, both of which are compatible with a wide range of industrial monitoring systems. -

What is the maximum measuring range of the sensor?

The maximum measuring range of the sensor is ±6.35 mm, making it ideal for measuring small deviations in the position and vibration of machinery. -

Is the 3300 NSv sensor suitable for use in extreme temperatures?

Yes, the sensor can operate in a temperature range from -40°C to 85°C, making it suitable for use in both hot and cold environments. -

How is the 3300 NSv sensor calibrated?

Calibration is performed through the connected vibration monitoring system, where users can set the baseline measurements and adjust for different operational conditions. -

Can the sensor be used for both vibration and position monitoring?

Yes, the 3300 NSv is designed to measure both vibration and position, making it ideal for comprehensive monitoring of rotating machinery. -

Can this sensor be integrated with other monitoring systems?

Yes, the sensor is compatible with most industrial monitoring systems, though it works most effectively when integrated with Bently Nevada’s machinery monitoring solutions. -

What is the frequency response of the 3300 NSv?

The sensor has a frequency response range from 5 kHz to 500 kHz, which allows it to accurately measure high-frequency vibrations in machinery. -

Is the sensor suitable for use in hazardous environments?

Yes, the 3300 NSv is built for rugged environments, including hazardous industrial conditions such as chemical plants, power generation facilities, and other challenging settings.

Related Models from the Same Series

Below are six other models from the Bently Nevada 3300 series:

| Model | Description |

|---|---|

| 330905-00-17-50-02-CN | 3300 NSv Proximity Sensor |

| 330500-00-10-10-02-CN | 3300 XL Proximity Transducer |

| 3300/05-11-01-00-CN | 3300 Proximity Transducer with Cable |

| 330130-00-00-00-02 | 3300 Series Speed Transducer |

| 330701-00-01-01-02 | 3300 RL Vibration Transducer |

| 330320-00-10-10-02-CN | 3300 NSv High-Performance Proximity |

Popular Models from Bently Nevada

Here are six popular models from Bently Nevada:

| Model | Description |

|---|---|

| 330905-00-13-05-02-05 | 3300 NSv Proximity Sensor with Cable |

| 330905-00-13-10-02-05 | 3300 NSv Proximity Transducer |

| 330905-00-12-10-02-00 | 3300 NSv Proximity Sensor |

| 330500-00-10-10-02-CN | 3300 XL Proximity Transducer |

| 330701-00-01-01-02 | 3300 RL Vibration Transducer |

| 330320-00-10-10-02-CN | 3300 NSv High-Performance Proximity |

Excellent PLC

Excellent PLC