| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

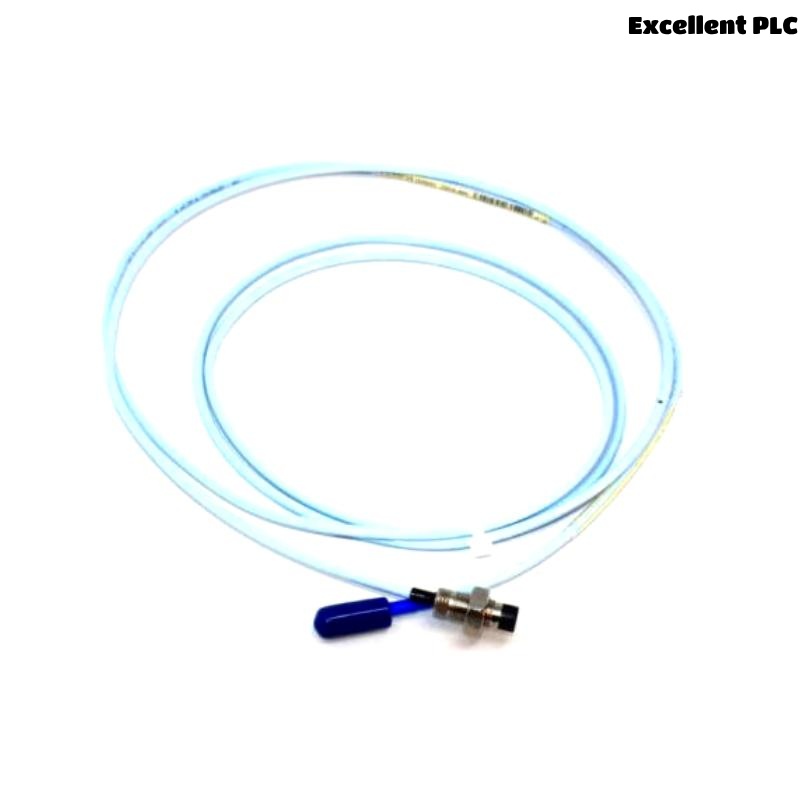

The Bently Nevada 330905-00-25-05-02 3300 NSv Proximity Probe is a rugged, high-performance sensor designed specifically for machinery condition monitoring in demanding industrial environments. This probe belongs to the 3300 NSv series, known for its robust construction and high accuracy in measuring shaft vibration and position.

With a focus on reliability and precision, the 3300 NSv probe features advanced sensor technology capable of detecting minute shaft movements to help prevent catastrophic machine failures. Its design caters to environments with high vibration, temperature fluctuations, and exposure to contaminants. This proximity probe plays a crucial role in rotating equipment monitoring systems by providing real-time data essential for predictive maintenance and operational safety.

Product Specifications

| Parameter | Description |

|---|---|

| Model Number | 330905-00-25-05-02 |

| Series | 3300 NSv |

| Probe Type | Proximity Probe |

| Sensing Distance (Gap) | 5 mm |

| Probe Diameter | 12.7 mm (0.5 inches) |

| Total Length | 0.5 meter |

| Cable Type | Shielded coaxial cable |

| Operating Temperature Range | -40°C to +125°C |

| Weight | 0.15 kg |

| Housing Material | Stainless steel |

| Connector Type | MIL-style connector |

| Vibration Resistance | Designed for high vibration environments |

| Measurement Range | Up to 5 mm sensing range |

| Accuracy | High sensitivity with micrometer-level repeatability |

Product Applications

The 3300 NSv 5mm Proximity Probe is widely used in critical machinery monitoring applications such as:

-

Steam and Gas Turbines: Monitoring shaft position and vibration to detect imbalance, misalignment, and wear.

-

Compressors: Providing vital shaft vibration data for early fault detection.

-

Motors and Generators: Continuous health monitoring to avoid unplanned downtime.

-

Pumps: Identifying bearing failures and misalignment through precise vibration measurement.

-

Heavy Industrial Equipment: Ideal for harsh environments in power plants, petrochemical plants, and refineries.

-

Rotating Machinery: General application for shaft position and vibration monitoring across various industries.

Product Advantages

-

Exceptional Precision: Delivers reliable shaft vibration and position measurements with micrometer-level accuracy.

-

Durable Construction: Stainless steel housing protects the sensor in extreme industrial conditions.

-

Wide Temperature Range: Functional between -40°C and +125°C, suitable for most industrial sites.

-

High Resistance to Vibration: Specifically designed to endure severe mechanical shocks and vibrations.

-

Secure Connections: MIL-style connectors ensure robust and consistent electrical connections.

-

Compatibility: Works seamlessly with Bently Nevada 3300 monitoring systems and signal conditioners.

-

Low Maintenance: Designed to minimize downtime and reduce calibration frequency.

-

Compact Form Factor: Easy to install in confined control cabinet spaces.

-

Trusted Brand Reliability: Produced by Bently Nevada, a global leader in machinery condition monitoring.

Frequently Asked Questions (FAQ)

-

Q: What is the sensing gap of this proximity probe?

A: The sensing gap is 5 mm, optimized for accurate shaft movement detection. -

Q: What temperature range can the probe operate within?

A: It operates reliably between -40°C and +125°C. -

Q: Is this probe compatible with Bently Nevada 3300 monitoring systems?

A: Yes, it is fully compatible and designed to integrate seamlessly. -

Q: What type of connector is used on this probe?

A: The probe uses an industry-standard MIL-style connector. -

Q: What is the physical size and weight of the probe?

A: The probe diameter is 12.7 mm, weighing 0.15 kg. -

Q: Does the probe require frequent maintenance or calibration?

A: No, it is designed for low maintenance and long-term stable operation. -

Q: What cable type does the probe use?

A: It employs a shielded coaxial cable for accurate and noise-resistant signal transmission. -

Q: Can this probe measure both shaft position and vibration?

A: Yes, it accurately measures both parameters critical to condition monitoring. -

Q: How resistant is the probe to vibration and shock?

A: It is specifically built to tolerate heavy vibration and mechanical shock typical of industrial machinery. -

Q: What industries commonly use this probe?

A: It is widely used in power generation, petrochemical plants, heavy industry, and rotating machinery applications.

Related Models from the Same Series or Related Bently Nevada Models

| Model Number | Sensing Gap | Probe Diameter | Cable Length (Typical) | Connector Type | Weight (kg) |

|---|---|---|---|---|---|

| 330905-00-25-05-02-01 | 3 mm | 12.7 mm | 200 mm | MIL-style | 0.15 |

| 330905-00-25-05-02-03 | 7 mm | 12.7 mm | 250 mm | MIL-style | 0.17 |

| 330905-00-25-05-02-04 | 10 mm | 12.7 mm | 300 mm | MIL-style | 0.18 |

| 330905-00-25-05-02-05 | 12 mm | 12.7 mm | 350 mm | MIL-style | 0.19 |

| 330905-00-25-05-02-06 | 15 mm | 12.7 mm | 400 mm | MIL-style | 0.20 |

| 330905-00-25-05-02-07 | 20 mm | 12.7 mm | 450 mm | MIL-style | 0.21 |

Popular Bently Nevada Models from the Same Brand

| Model Number | Description | Sensor Type | Application Area | Weight (kg) |

|---|---|---|---|---|

| 330102-00-28-05-02-05 | 3300 XL 8mm Proximity Probe | Proximity Probe | Shaft vibration sensing | 0.15 |

| 330106-00-02-05-02-01 | 3300 XL Velomitor Probe | Velocity Probe | Vibration velocity | 0.20 |

| 3500/25-00-00-00-00 | 3500 Monitor | Condition Monitor | Machine protection | 2.0 |

| 3300 XL Proximitor | Signal Conditioning Unit | Signal Conditioner | Signal processing | 0.8 |

| 330102-00-28-05-02-02 | 3300 XL 5mm Proximity Probe | Proximity Probe | Shaft position sensing | 0.14 |

| 330108-00-28-05-02-03 | 3300 XL 12mm Proximity Probe | Proximity Probe | Extended sensing range | 0.18 |

Excellent PLC

Excellent PLC