| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Overview

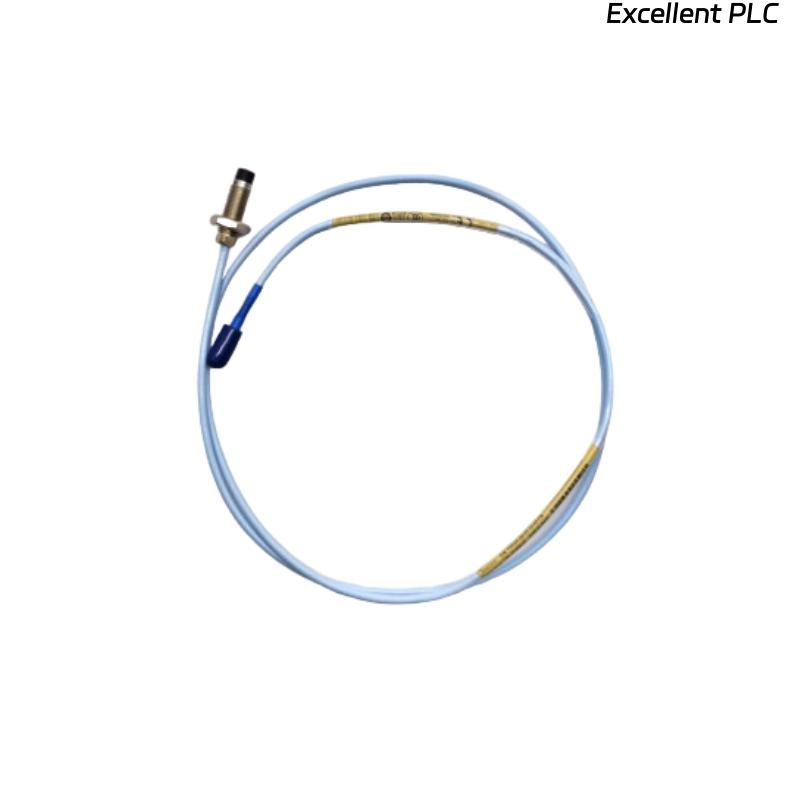

The Bently Nevada 330905-06-10-10-02-00 3300 NSv Proximity Sensor is designed for industries that rely on precision in their machinery monitoring systems. With its advanced technology, this sensor is highly effective for detecting early signs of wear, misalignment, or other mechanical issues in critical rotating machinery. By monitoring vibrations and positional changes, this sensor plays a vital role in predictive maintenance programs, helping prevent unplanned downtime and costly repairs.

A standout feature of this sensor is its non-contact measurement technology, which offers exceptional durability and reliability compared to traditional contact-based sensors. Additionally, the sensor is designed for easy integration with existing monitoring systems, making it a flexible choice for companies looking to enhance their machinery protection strategies.

Key Specifications

Below are the key technical specifications for the Bently Nevada 330905-06-10-10-02-00 sensor:

| Specification | Value |

|---|---|

| Model | 330905-06-10-10-02-00 |

| Type | 3300 NSv Proximity Sensor |

| Total Length | 1.0 meter |

| Weight | 0.15 kg |

| Measurement Range | ±6.35 mm |

| Output Signals | 4-20 mA, 0-10 VDC |

| Operating Temperature | -40°C to 85°C |

| Power Supply | 18 to 30 VDC |

| Signal Type | Differential, Linear Analog |

| Frequency Range | 5 kHz to 500 kHz |

| Housing Material | Stainless Steel |

Applications

The 3300 NSv Proximity Sensor is commonly employed in industries requiring precise condition monitoring of rotating machinery. Its non-contact technology makes it ideal for applications where traditional sensors would wear out quickly due to high mechanical stresses. Below are some of the most common applications for the 3300 NSv:

-

Turbines: The sensor is widely used to monitor turbine rotors, ensuring balanced operation and early detection of any abnormal vibration or misalignment.

-

Motors: Used in electric motors to track vibration and shaft positioning, helping to prevent misalignment and reduce the risk of bearing failure.

-

Compressors: Provides real-time data on compressor shaft movement, helping to detect early signs of mechanical failure before they lead to downtime.

-

Pumps and Fans: Monitors large pumps and fans, detecting changes in vibration or misalignment that could indicate potential failure.

-

General Rotating Machinery: Suitable for a wide range of rotating equipment, including blowers, mixers, and conveyors, where monitoring vibration is crucial to maintaining performance and reliability.

Key Advantages

-

Non-Contact Measurement: By using non-contact technology, the 3300 NSv sensor minimizes wear and tear, extending its lifespan and maintaining consistent performance over time.

-

High Measurement Accuracy: The sensor provides high-precision readings, which is crucial for effective predictive maintenance and ensuring the long-term reliability of rotating machinery.

-

Wide Temperature Tolerance: Operating effectively within a temperature range from -40°C to 85°C, it can withstand extreme conditions typically found in heavy-duty industrial environments.

-

Rugged and Durable: With a stainless steel housing, the 3300 NSv is built to resist corrosion, moisture, and other harsh conditions, ensuring durability even in challenging environments.

-

Ease of Integration: The sensor is designed to integrate seamlessly with both Bently Nevada monitoring systems and third-party solutions, offering great flexibility for various industrial needs.

-

Cost-Effective: By facilitating early fault detection, the sensor helps reduce the likelihood of unexpected machinery failures and costly repairs, leading to significant cost savings in maintenance and downtime reduction.

FAQ

-

What is the primary purpose of the 3300 NSv sensor?

The 3300 NSv sensor is primarily used for measuring vibration and position in rotating machinery to detect potential issues early, enabling predictive maintenance. -

What differentiates the 3300 NSv from other proximity sensors?

Unlike traditional proximity sensors, the 3300 NSv uses non-contact measurement technology, which prevents mechanical wear and ensures long-term, reliable performance in demanding industrial environments. -

What types of outputs does the 3300 NSv provide?

This sensor provides analog outputs: a 4-20 mA signal and a 0-10 VDC signal, both of which are standard in industrial monitoring applications. -

What is the effective measurement range of the sensor?

The 3300 NSv has a measuring range of ±6.35 mm, which allows it to detect small changes in vibration and position in rotating machinery. -

How does the 3300 NSv handle temperature fluctuations?

The sensor can operate within a wide temperature range of -40°C to 85°C, making it suitable for both extremely cold and hot industrial environments. -

How do I calibrate the 3300 NSv sensor?

Calibration is typically done through the connected vibration monitoring system, allowing for precise adjustments to match specific machinery and operational conditions. -

Can the 3300 NSv sensor measure both vibration and position?

Yes, the 3300 NSv is capable of measuring both vibration and position, offering comprehensive monitoring of rotating machinery. -

Is the 3300 NSv compatible with third-party systems?

Yes, the sensor can be integrated with both Bently Nevada’s proprietary systems and other third-party monitoring equipment, offering flexibility for various setups. -

What is the frequency response range of the 3300 NSv?

The 3300 NSv has a frequency response range from 5 kHz to 500 kHz, ensuring it can accurately capture high-frequency vibrations. -

Can the 3300 NSv sensor be used in hazardous environments?

Yes, the 3300 NSv is designed to operate in harsh industrial environments, including those exposed to moisture, chemicals, and extreme physical stress.

Related Models from the Same Series

Here are six other models from the Bently Nevada 3300 series:

| Model | Description |

|---|---|

| 330905-06-10-10-02-00 | 3300 NSv Proximity Sensor |

| 330500-00-10-10-02-CN | 3300 XL Proximity Transducer |

| 3300/05-11-01-00-CN | 3300 Proximity Transducer with Cable |

| 330130-00-00-00-02 | 3300 Series Speed Transducer |

| 330701-00-01-01-02 | 3300 RL Vibration Transducer |

| 330320-00-10-10-02-CN | 3300 NSv High-Performance Proximity |

Popular Models from Bently Nevada

Here are six popular models from Bently Nevada:

| Model | Description |

|---|---|

| 330905-01-08-10-01-00 | 3300 NSv Proximity Sensor |

| 330905-01-10-05-02-05 | 3300 NSv Proximity Transducer |

| 330905-01-10-10-02-00 | 3300 NSv High-Performance Proximity Sensor |

| 330905-01-09-05-02-00 | 3300 NSv Proximity Sensor with Cable |

| 330905-01-08-05-02-10 | 3300 NSv Proximity Sensor with Extension |

| 330905-01-07-10-02-05 | 3300 NSv Proximity Transducer with High Accuracy |

Excellent PLC

Excellent PLC