| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

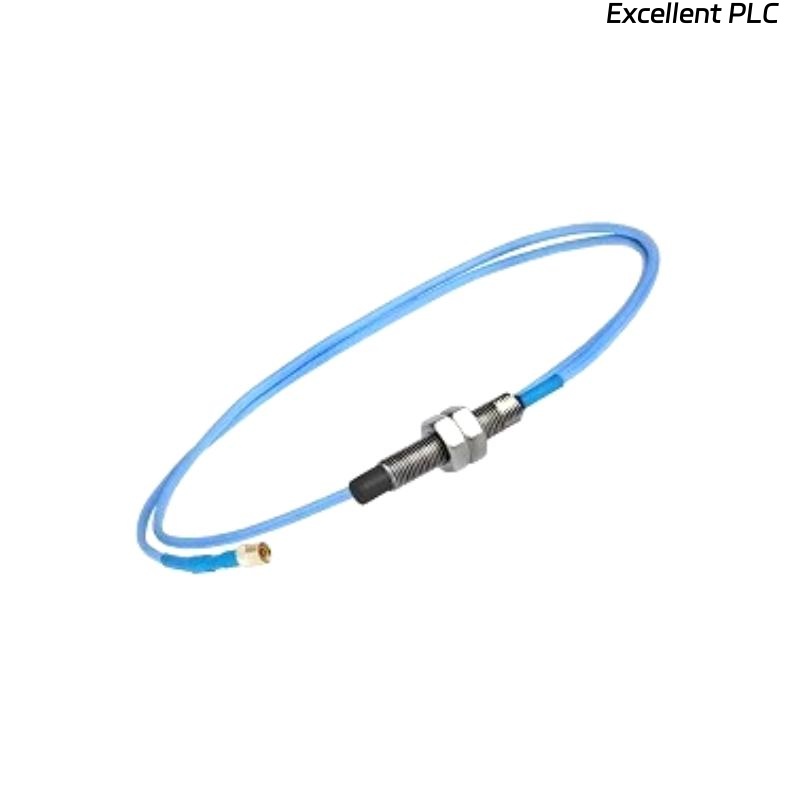

The Bently Nevada 330905-10-18-50-02-00 3300 NSv Proximity Probe is a precision shaft displacement sensor designed for rotating machinery condition monitoring. Part of the 3300 NSv Series, it provides accurate and reliable measurements of shaft position, essential for early detection of machinery faults, predictive maintenance, and operational safety.

This probe comes with a 5.0-metre cable and a compact design that allows installation in tight industrial spaces. Built with a stainless steel probe body and shielded cable, it ensures high-fidelity signal transmission even in environments with mechanical vibration, electrical noise, or temperature fluctuations.

The 330905-10-18-50-02-00 probe is commonly used in turbines, compressors, motors, and pumps, providing operators with real-time data on shaft vibration, misalignment, unbalance, or bearing wear, enabling preventive maintenance actions before critical failures occur.

Technical Specifications

| Parameter | Description |

|---|---|

| Model | Bently Nevada 330905-10-18-50-02-00 |

| Series | 3300 NSv |

| Probe Type | Proximity displacement sensor |

| Total Length | 5.0 metres |

| Weight | 0.15 kg |

| Material | Stainless steel probe body with shielded cable |

| Signal Type | Analog proximity signal compatible with 3300 NSv monitors |

| Mounting Style | Threaded or clamp mount |

| Operating Temperature Range | -40°C to +120°C |

| Frequency Response | Suitable for high-speed rotating machinery |

| Tip Diameter | Standard NSv configuration |

| System Compatibility | Bently Nevada 3300 NSv monitoring systems |

| Certifications | CE marked, RoHS compliant |

Product Applications

The 330905-10-18-50-02-00 probe is designed for a wide range of industrial applications:

-

Rotating Machinery Monitoring: Measures shaft displacement in turbines, motors, compressors, and pumps.

-

Predictive Maintenance: Enables early detection of machinery issues to prevent unplanned downtime.

-

Vibration Analysis: Supplies high-fidelity analog signals for analysis using 3300 NSv monitoring systems.

-

Industrial Automation: Monitors shaft position for operational safety and precision control.

-

Energy Sector: Suitable for steam, gas, and hydro turbines.

-

Heavy Industry Applications: Steel, mining, and pulp and paper machinery monitoring.

Product Advantages

-

High Accuracy: Provides precise shaft displacement measurements for critical monitoring.

-

Robust Design: Stainless steel body and shielded cable ensure reliability in harsh environments.

-

Compact and Flexible: Ideal for installations in tight spaces with a 5.0-metre cable.

-

Low-Noise Signal Transmission: Shielded cable minimizes interference from electromagnetic sources.

-

Predictive Maintenance Support: Enables early identification of faults to reduce operational risk.

-

Wide Temperature Range: Operates effectively from -40°C to +120°C.

-

High-Speed Compatibility: Maintains accuracy in high-speed rotating machinery.

-

System Integration: Fully compatible with 3300 NSv Series monitors.

-

Industrial Reliability: Resistant to vibration, EMI, and temperature fluctuations.

-

Ease of Installation: Threaded or clamp mount design for flexible integration.

FAQ

1. What type of signal does the 330905-10-18-50-02-00 probe provide?

It outputs an analog proximity signal compatible with Bently Nevada 3300 NSv monitoring systems.

2. What is the total cable length for this probe?

The probe comes with a 5.0-metre cable for flexible installation.

3. Is the cable shielded to prevent interference?

Yes, the cable is shielded to minimize electromagnetic interference and maintain signal integrity.

4. What is the operating temperature range of this probe?

It operates reliably between -40°C and +120°C.

5. Can this probe be used with high-speed machinery?

Yes, it is designed for high-speed turbines, motors, compressors, and pumps.

6. How is the probe mounted?

It supports threaded or clamp mounting for flexible installation.

7. Is this probe compatible with Bently Nevada 3300 NSv systems?

Yes, it is fully compatible with 3300 NSv monitoring systems.

8. Can this probe support predictive maintenance programs?

Yes, it provides continuous displacement data to enable early fault detection.

9. Does the probe maintain accuracy in electrically noisy environments?

Yes, the shielded cable and robust construction ensure reliable measurements under high EMI conditions.

10. What types of machinery are suitable for this probe?

It is suitable for turbines, compressors, pumps, motors, and other rotating machinery requiring precise shaft displacement monitoring.

Related Models (Same Series)

| Model | Description |

|---|---|

| 330905-10-18-50-02-01 | NSv probe with alternate tip configuration |

| 330905-10-18-50-02-03 | NSv probe with extended cable option |

| 330905-10-18-50-02-04 | High-temperature NSv probe |

| 330905-10-18-50-02-05 | EMI-shielded NSv probe |

| 330905-10-18-50-02-06 | Compact NSv probe for tight installation spaces |

| 330905-10-18-50-02-07 | NSv probe with reinforced mechanical tip |

Popular Bently Nevada Models

| Model | Description |

|---|---|

| 3300 XL Proximitor | High-precision proximity sensor for shaft monitoring |

| 3300 XL Accelerometer | Standard accelerometer for vibration monitoring |

| 2300 Vibration Transducer | Industrial sensor for vibration measurement |

| 3500 Series Monitoring System | Complete machinery protection and monitoring system |

| 7200 Series Wireless Sensor | Wireless sensor solution for rotating machinery |

| 9500 Series Wireless Sensor | Compact wireless sensor for predictive maintenance and vibration monitoring |

Excellent PLC

Excellent PLC