| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

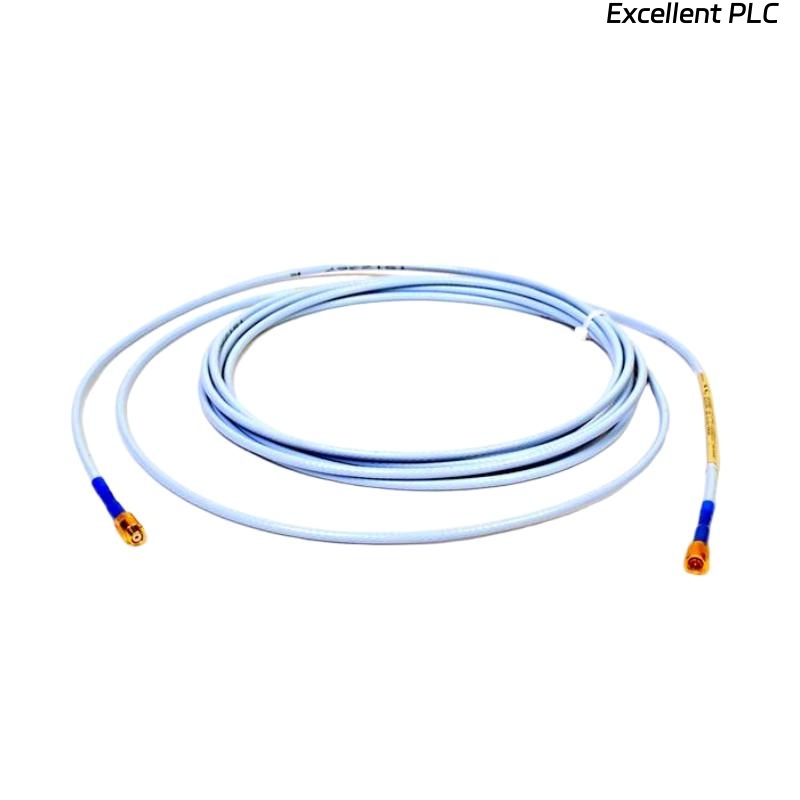

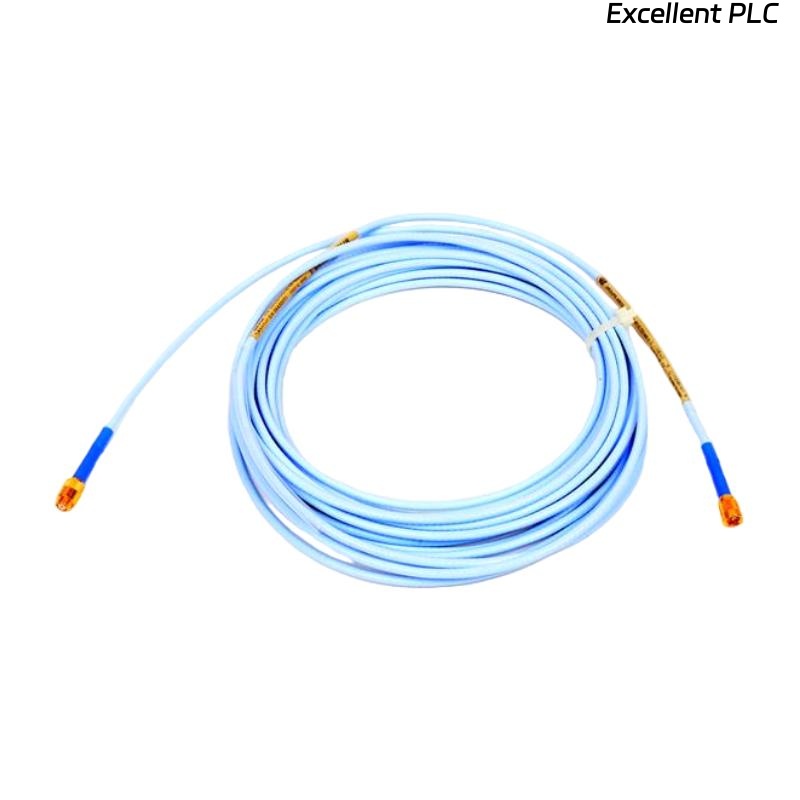

The Bently Nevada 330906-02-12-05-02-CN 3300 NSv Reverse Mount Probe is a high-precision eddy current proximity sensor designed for measuring the dynamic and static position of machine shafts and rotors in industrial rotating equipment. As part of the 3300 NSv (Narrow Signal variant) system, this probe is specifically optimized for small or compact machines, providing reliable displacement measurements where standard probes cannot be easily installed.

This reverse mount version allows the sensing element to be installed from the rear of the mounting surface, making it ideal for applications where direct forward access is limited or restricted. With its 0.5-meter total cable length, the probe ensures minimal signal loss while maintaining high accuracy and stability. Constructed with stainless steel housing and a shielded cable, it offers exceptional resistance to electromagnetic interference (EMI), vibration, and harsh industrial environments.

Engineered for precise shaft vibration and position monitoring, the 330906-02-12-05-02-CN probe integrates seamlessly with Bently Nevada 3300 NSv Proximitor® sensors and monitoring systems, ensuring consistent performance in turbines, compressors, motors, and pumps.

Technical Specifications

| Parameter | Description |

|---|---|

| Model | 330906-02-12-05-02-CN |

| Series | Bently Nevada 3300 NSv Reverse Mount Probe |

| Probe Type | Eddy current proximity probe |

| Mounting Type | Reverse mount (rear access installation) |

| Total Length | 0.5 meter |

| Weight | 0.15 kg |

| Probe Body Material | Stainless steel |

| Cable Type | Shielded low-noise coaxial cable |

| Measurement Range | Nominal 2 mm range (linear) |

| Operating Temperature Range | -35°C to +120°C |

| Frequency Response | DC to 10 kHz (typical) |

| System Compatibility | Bently Nevada 3300 NSv Proximitor and monitoring systems |

| Output Signal | Analog voltage proportional to shaft displacement |

| Sensitivity | 7.87 mV/μm (nominal) |

| Mounting Thread | M10 × 1 or equivalent (custom depending on configuration) |

| Environmental Protection | IP67 rated, resistant to oil and vibration |

| Compliance | CE, RoHS, ISO9001 manufacturing standards |

Product Applications

The 330906-02-12-05-02-CN Reverse Mount Probe is widely used across various industries that rely on continuous and accurate machinery condition monitoring. Typical applications include:

-

Turbomachinery Monitoring: Measurement of shaft vibration, position, and eccentricity in steam, gas, and hydro turbines.

-

Compressors and Pumps: Real-time monitoring of shaft displacement to detect bearing wear or unbalance.

-

Electric Motors and Generators: Tracking rotor movement and shaft centerline position.

-

Industrial Fans and Blowers: Ensuring stable mechanical performance and vibration control.

-

Aerospace and Marine Systems: Compact installation capability makes it suitable for constrained environments.

-

Predictive Maintenance Systems: Integration with monitoring equipment for fault detection and machinery protection.

Product Advantages

-

Reverse Mount Design: Allows installation from the rear side of the machine housing, suitable for limited-access environments.

-

Compact and Lightweight: Ideal for small machines where space constraints prevent standard probe installation.

-

High Signal Integrity: Shielded cable reduces electrical noise and signal distortion.

-

Exceptional Measurement Accuracy: Provides stable and repeatable displacement readings under dynamic conditions.

-

Wide Operating Temperature Range: Ensures reliable operation from -35°C to +120°C.

-

Durable Construction: Stainless steel probe housing offers excellent corrosion and vibration resistance.

-

Full System Compatibility: Designed to work seamlessly with the Bently Nevada 3300 NSv Proximitor® sensors and monitoring systems.

-

Ease of Integration: Simplifies installation and calibration processes for existing condition monitoring setups.

-

Predictive Maintenance Support: Enables early detection of misalignment, imbalance, and bearing degradation.

-

Long-Term Reliability: Proven GE/Bently Nevada engineering quality ensures consistent performance in critical applications.

FAQ

1. What is the primary purpose of the 330906-02-12-05-02-CN probe?

It measures shaft vibration and position in rotating machinery using an eddy current sensing principle.

2. How is the reverse mount probe different from a standard mount probe?

The reverse mount version is installed from behind the mounting surface, useful where front access is restricted.

3. What is the compatible monitoring system for this probe?

It is designed for use with Bently Nevada 3300 NSv Proximitor® sensors and monitoring systems.

4. What is the nominal linear measurement range of this probe?

The probe typically supports a 2 mm linear range for precise displacement monitoring.

5. How is the probe protected against interference?

It uses a shielded low-noise coaxial cable to minimize electromagnetic interference and signal distortion.

6. Can this probe operate under high temperatures?

Yes, it operates effectively between -35°C and +120°C, suitable for industrial environments.

7. What type of output signal does the probe produce?

It outputs an analog voltage proportional to the shaft’s proximity or vibration amplitude.

8. Is the probe suitable for high-speed machinery applications?

Yes, it can handle frequency responses up to 10 kHz, ideal for turbines, compressors, and motors.

9. How does the reverse mount design aid in maintenance?

It enables easier replacement and inspection without dismantling the entire machine housing.

10. What materials are used for the probe’s construction?

The probe is made from stainless steel for corrosion resistance and long-term reliability in harsh environments.

Related Models (Same Series)

| Model | Description |

|---|---|

| 330906-02-12-05-02 | Standard 3300 NSv probe, forward mount design |

| 330906-02-12-10-02 | Extended cable version for long-distance installation |

| 330906-02-12-05-05 | High-temperature reverse mount probe |

| 330906-02-12-05-07 | EMI-hardened probe for industrial machinery |

| 330906-02-12-05-09 | Compact reverse mount version for tight spaces |

| 330906-02-12-05-11 | Enhanced sensitivity variant for low-amplitude vibration detection |

Popular Bently Nevada Models

| Model | Description |

|---|---|

| 3300 XL Proximitor Sensor | Advanced proximity sensor for shaft vibration monitoring |

| 3300 XL 8mm Proximity Probe | Standard shaft position probe for industrial applications |

| 330400 Proximitor Sensor | General-purpose displacement monitoring sensor |

| 3500/22M Transient Data Interface | Condition monitoring module for advanced diagnostics |

| 7200 Series Proximity Probe | Compact probe for high-speed rotating machinery |

| 3500/42M Proximitor Monitor | Multi-channel vibration and position monitoring system |

Excellent PLC

Excellent PLC