| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

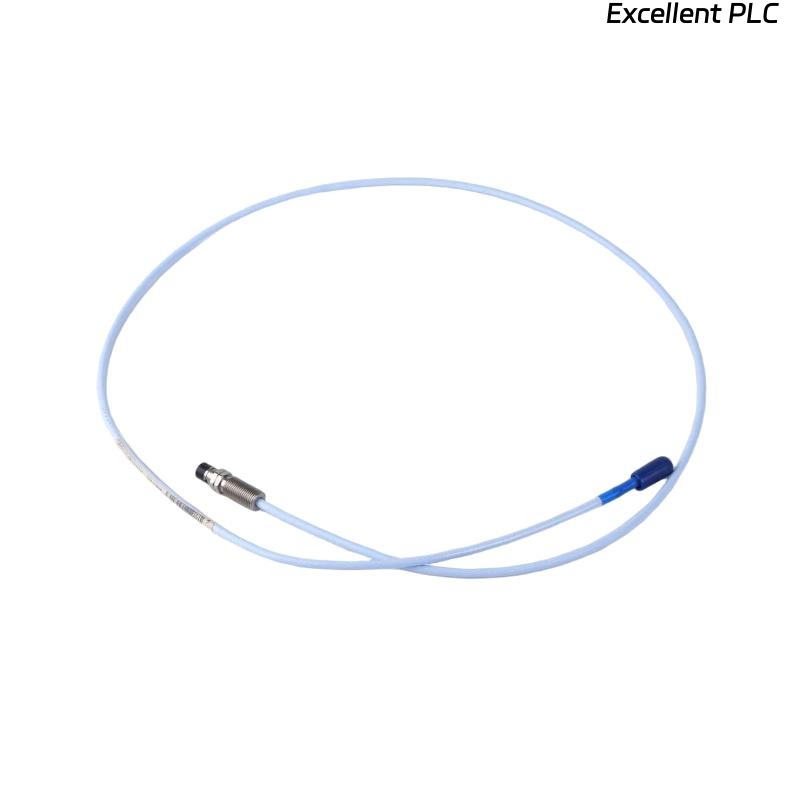

The Bently Nevada 330907-05-30-05-02-05 3300 NSv Reverse Mount Probe is a high-performance proximity probe engineered for precise measurement of shaft vibration and position in rotating machinery. As part of the 3300 NSv (Narrow Signal variant) system, it is specifically designed for applications involving small or compact machines, such as small gas turbines, compressors, and pumps, where space is limited but accuracy and reliability are critical.

This model features a reverse mount design, allowing the probe to be installed from the back side of the mounting surface, which simplifies installation in confined areas or where front-side access is restricted. The probe utilizes eddy current technology to provide highly accurate non-contact measurement of the distance between the probe tip and the machine’s rotating shaft.

Built with stainless steel housing and a shielded low-noise coaxial cable, the 330907-05-30-05-02-05 probe offers excellent resistance to electromagnetic interference (EMI), mechanical vibration, and harsh industrial conditions. Its 0.5-meter cable length ensures flexibility for short-distance installations while maintaining outstanding signal integrity.

Technical Specifications

| Parameter | Description |

|---|---|

| Model | 330907-05-30-05-02-05 |

| Series | Bently Nevada 3300 NSv Reverse Mount Probe |

| Probe Type | Eddy current proximity probe |

| Mounting Type | Reverse mount (rear access installation) |

| Total Length | 0.5 meter |

| Weight | 0.15 kg |

| Material | Stainless steel probe body |

| Cable Type | Shielded low-noise coaxial cable |

| Measurement Range | 2 mm nominal linear range |

| Operating Temperature Range | -35°C to +120°C |

| Frequency Response | DC to 10 kHz (typical) |

| Sensitivity | 7.87 mV/μm (nominal) |

| System Compatibility | Bently Nevada 3300 NSv Proximitor® Sensor |

| Output Signal | Analog voltage proportional to shaft displacement |

| Mounting Thread | M10 × 1 or equivalent configuration |

| Environmental Protection | IP67-rated for moisture, oil, and vibration resistance |

| Compliance | CE, RoHS, ISO9001-certified manufacturing standards |

Product Applications

The 330907-05-30-05-02-05 Reverse Mount Probe is extensively used in rotating machinery monitoring and predictive maintenance applications. Its compact, durable, and reverse-mount configuration makes it ideal for a variety of industries and machine types, including:

-

Small Gas and Steam Turbines: Monitoring shaft vibration and position for early fault detection.

-

Compressors and Blowers: Tracking bearing wear and rotor imbalance.

-

Industrial Pumps: Ensuring operational stability and shaft alignment.

-

Electric Motors and Generators: Measuring dynamic shaft displacement and eccentricity.

-

Marine and Aerospace Machinery: Perfect for tight installations in compact systems.

-

Power Generation and Petrochemical Equipment: Providing reliable feedback for condition-based maintenance.

Product Advantages

-

Reverse Mount Design: Enables installation from the rear side of machinery housing, allowing access in confined or restricted locations.

-

Compact and Lightweight: Ideal for small equipment and narrow installation spaces.

-

High Accuracy Measurement: Offers precise displacement data for accurate shaft vibration analysis.

-

Excellent Signal Integrity: Shielded coaxial cable minimizes electrical noise and interference.

-

Durable Construction: Stainless steel body provides corrosion resistance and long-term reliability in harsh industrial environments.

-

Wide Temperature Range: Designed to perform reliably from -35°C to +120°C.

-

Compatible with 3300 NSv Systems: Ensures full functionality with Bently Nevada’s monitoring infrastructure.

-

Predictive Maintenance Support: Allows early detection of misalignment, bearing wear, and imbalance.

-

Low Maintenance Requirements: Robust mechanical and electrical design minimizes operational downtime.

-

Proven GE/Bently Nevada Engineering: Trusted quality and performance for critical monitoring systems worldwide.

FAQ

1. What is the primary function of the 330907-05-30-05-02-05 probe?

It measures shaft vibration and static position using eddy current sensing technology to provide precise displacement data for rotating machinery.

2. What distinguishes this reverse mount probe from a standard mount version?

The reverse mount configuration installs from the back side of the mounting surface, making it ideal for restricted access or confined spaces.

3. Which monitoring systems are compatible with this probe?

It is specifically designed for use with the Bently Nevada 3300 NSv Proximitor® Sensor and monitoring systems.

4. What is the linear measurement range of the probe?

It offers a nominal linear range of approximately 2 mm, ensuring accurate proximity and vibration readings.

5. What type of cable is used in this probe?

The probe features a shielded low-noise coaxial cable, which enhances signal integrity and reduces EMI effects.

6. Can the probe be used in high-vibration environments?

Yes, it is IP67-rated and built with vibration-resistant materials suitable for heavy industrial conditions.

7. What kind of output does the probe generate?

It outputs an analog voltage signal proportional to the measured shaft displacement or vibration amplitude.

8. How does this probe support predictive maintenance programs?

By providing real-time vibration and position data, it enables early detection of potential faults such as bearing failure or misalignment.

9. Is it suitable for high-speed rotating machinery?

Yes, with a frequency response up to 10 kHz, it can effectively monitor high-speed turbines, compressors, and pumps.

10. How does temperature affect the probe’s performance?

The probe is designed to maintain stable performance across a wide temperature range from -35°C to +120°C, ensuring reliable readings under thermal stress.

Related Models (Same Series)

| Model | Description |

|---|---|

| 330907-05-30-05-02-00 | Standard 3300 NSv reverse mount probe |

| 330907-05-30-05-02-02 | Reverse mount probe with extended cable |

| 330907-05-30-05-02-03 | EMI-shielded probe for industrial environments |

| 330907-05-30-05-02-06 | Compact reverse mount probe for small turbines |

| 330907-05-30-05-02-07 | High-temperature version with stainless steel body |

| 330907-05-30-05-02-08 | Enhanced sensitivity probe for precise vibration monitoring |

Popular Bently Nevada Models

| Model | Description |

|---|---|

| 3300 XL 8mm Proximity Probe | Standard vibration probe for industrial machinery |

| 3300 XL Proximitor Sensor | Signal conditioning unit for proximity probes |

| 3500/42M Proximitor Monitor | Four-channel vibration and position monitor |

| 3500/22M Transient Data Interface | Data acquisition module for transient vibration analysis |

| 330400 Proximitor Sensor | Compact sensor for shaft displacement monitoring |

| 7200 Series Proximity Probe | Durable probe for general-purpose machinery vibration detection |

Excellent PLC

Excellent PLC