| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

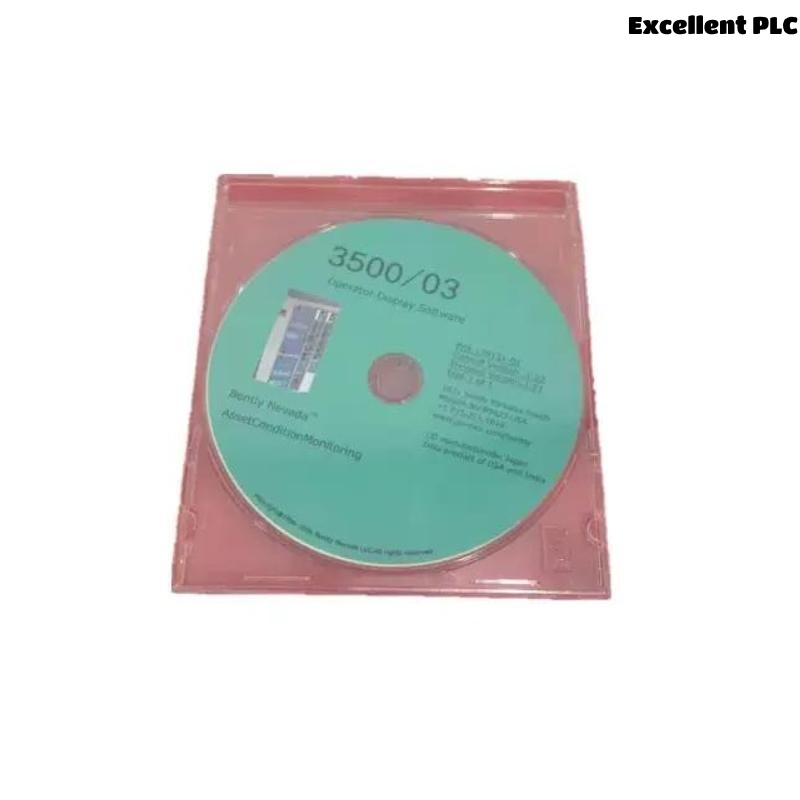

Product Overview

The Bently Nevada 3500/03 129131-01 Rack Configuration Software is a sophisticated and essential tool designed for configuring and managing the 3500 series machinery protection and condition monitoring systems. The software is an integral part of the 3500 series, providing an easy-to-use graphical interface to configure racks, monitor system performance, and optimize the setup for various machinery monitoring applications.

This powerful software supports the configuration of Bently Nevada’s wide range of sensors, such as vibration, temperature, and proximity sensors, enabling seamless integration into the 3500 monitoring system. The software simplifies the process of sensor calibration, alarm threshold settings, and real-time diagnostics, making it an indispensable tool for improving the reliability and accuracy of industrial machinery health monitoring.

The 3500/03 129131-01 software is specifically designed for use in industrial environments where minimizing downtime and ensuring continuous operation of critical machinery is a priority. This tool is a perfect solution for industries such as power generation, oil and gas, heavy manufacturing, and transportation, where machinery health is critical to operational efficiency.

Technical Specifications

| Parameter | Description |

|---|---|

| Model Number | 3500/03 129131-01 |

| Brand | Bently Nevada |

| Product Type | Rack Configuration Software |

| Shipping Weight | 2 kg |

| Dimensions | Please contact customer service for dimensions |

| Operating System | Windows OS (specific versions) |

| Interface | Graphical User Interface (GUI) |

| License | Software license for one system configuration |

| Application | Industrial Machinery Monitoring and Protection |

| System Compatibility | Compatible with Bently Nevada 3500 Series |

| Installation | Easy-to-install package with user-friendly setup |

| Environmental Rating | Indoor use, IP20 rated |

| Power Requirements | 24V DC or system provided power |

| Communication Protocol | Serial communication or Ethernet (depending on system) |

Applications

-

Industrial Machinery Monitoring

The 3500/03 software is specifically designed for configuring and managing machinery health monitoring systems in industrial environments. It supports the integration of vibration, temperature, and proximity sensors, ensuring accurate and real-time data collection for condition monitoring. The software is indispensable in environments where machinery uptime is critical. -

Power Generation

In power plants, the software plays a key role in the configuration of turbines, compressors, and other critical machinery. By accurately configuring the monitoring system, the software ensures that any deviations from normal operating conditions are quickly identified, allowing for early intervention and avoiding costly downtime. -

Oil & Gas Industry

The software is commonly used in the oil and gas industry, where machinery such as pumps, motors, and turbines require constant monitoring. The software’s ability to integrate sensors seamlessly ensures that operations can be safely managed, and issues can be detected before they lead to system failures. -

Manufacturing and Heavy Industry

The 3500/03 software is used in manufacturing facilities to optimize machinery monitoring. It helps ensure that all equipment is functioning optimally and allows operators to identify potential problems early, reducing unplanned downtime and improving overall operational efficiency. -

Transportation and Aerospace

The software is employed in the aerospace and transportation industries to monitor the health of engines, turbines, and other essential systems. By ensuring early detection of any faults, it helps prevent mechanical failure that could lead to catastrophic outcomes. -

Mining

In mining operations, where machinery is subjected to extreme environments, the software is used to configure and maintain condition monitoring systems for crushers, mills, and other critical equipment. This proactive monitoring ensures that maintenance is performed before a failure can occur, minimizing the risk of downtime.

Advantages

-

User-Friendly Interface

The 3500/03 software features a graphical user interface (GUI) that is easy to navigate, making it simple for operators to configure, monitor, and manage machinery health systems. The intuitive design reduces the learning curve and allows operators to make quick adjustments to system settings. -

Seamless System Integration

This software integrates seamlessly with the Bently Nevada 3500 monitoring systems, providing an all-in-one solution for system configuration and management. The ability to quickly configure sensors and adjust system parameters enhances operational efficiency. -

Real-Time Data Monitoring

The software provides real-time monitoring of machinery health, ensuring that operators receive up-to-the-minute data on the performance of critical equipment. With real-time alerts and system diagnostics, any issues are quickly detected, reducing the likelihood of unexpected failures. -

Comprehensive Diagnostic Tools

The software includes advanced diagnostic features that help identify problems early, making it easier to schedule maintenance and repair activities. It provides detailed reports on sensor performance and system health, ensuring that any problems are addressed promptly. -

Improved Operational Efficiency

By automating many of the configuration and monitoring tasks, the software reduces the amount of manual intervention required. This not only saves time but also increases the overall accuracy and efficiency of the system, helping operators to optimize machine performance. -

Enhanced Reliability

The 3500/03 software ensures that the entire machinery health monitoring system is properly configured and optimized. This leads to improved system reliability, helping operators to reduce downtime and extend the lifespan of their equipment.

FAQs

Q1: What is the main function of the Bently Nevada 3500/03 129131-01 Rack Configuration Software?

A1: The main function of this software is to configure, manage, and optimize Bently Nevada’s 3500 machinery protection and condition monitoring systems. It enables the seamless integration of various sensors and provides real-time data for effective monitoring.

Q2: What are the system requirements for the software?

A2: The software is compatible with Windows OS (specific versions may vary). It requires a system with sufficient hardware capacity to run Bently Nevada’s monitoring tools.

Q3: How does the software integrate with the Bently Nevada 3500 series?

A3: The software integrates directly with the 3500 series monitoring racks, enabling users to configure sensors, set alarm thresholds, and perform real-time diagnostics seamlessly.

Q4: Can the software be used for large-scale systems with multiple racks?

A4: Yes, the 3500/03 software is designed for large-scale systems and can be used to configure and manage multiple racks in an industrial setting.

Q5: How does the software improve system accuracy?

A5: By automating configuration tasks and providing real-time monitoring, the software ensures that sensor data is accurately transmitted and that systems are properly configured to detect potential issues before they lead to failure.

Q6: Is the software easy to install?

A6: Yes, the software comes with an easy-to-follow installation guide. The package can be downloaded, and the installation process is straightforward for users with basic technical knowledge.

Q7: What is the shipping weight of the 3500/03 software?

A7: The shipping weight of the software is 2 kg.

Q8: What dimensions does the software package have?

A8: Please contact Bently Nevada customer service for specific dimensional information.

Q9: What types of sensors are compatible with the software?

A9: The software is compatible with a wide range of Bently Nevada sensors, including vibration, temperature, and proximity sensors.

Q10: How does the software handle system diagnostics?

A10: The software includes advanced diagnostic tools that provide detailed information on system health, allowing operators to identify potential issues and perform necessary maintenance or repairs.

Related Models (Same Series or Function)

| Model | Description | Type | Key Feature | Shipping Weight | Dimensions |

|---|---|---|---|---|---|

| 3500/03 129131-02 | Advanced rack configuration software | Configuration Tool | Provides additional features | 2 kg | Please inquire |

| 3500/03 129131-03 | Basic version with simplified configuration process | Configuration Tool | Ideal for smaller setups | 2 kg | Please inquire |

| 3500/03 129131-04 | Enhanced version with cloud capabilities | Configuration Software | Cloud-based data access | 2 kg | Please inquire |

| 3500/03 129131-05 | Version supporting multi-rack systems | Configuration Tool | Multi-rack support | 2 kg | Please inquire |

| 3500/03 129131-06 | Software with expanded sensor integration features | Configuration Tool | Additional sensor support | 2 kg | Please inquire |

| 3500/03 129131-07 | Full-featured version with advanced diagnostic tools | Configuration Software | Advanced diagnostics & reports | 2 kg | Please inquire |

Popular Bently Nevada Modules (Same Brand)

| Model | Description | Dimensions (mm) |

|---|---|---|

| 330980-50-00 | Proximity probe, 50mm, standard version | 100 x 30 x 20 |

| 330980-50-05 | Proximity probe, 50mm, extended range | 100 x 30 x 20 |

| 330980-50-CN | Proximity probe, 50mm, standard version, Chinese interface | 100 x 30 x 20 |

| 330980-51-00 | Proximity probe, 50mm, high-accuracy version | 100 x 30 x 20 |

| 330980-51-05 | Proximity probe, 50mm, high-accuracy, extended range | 100 x 30 x 20 |

| 330980-51-CN | Proximity probe, 50mm, high-accuracy, Chinese interface | 100 x 30 x 20 |

Excellent PLC

Excellent PLC