| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Overview

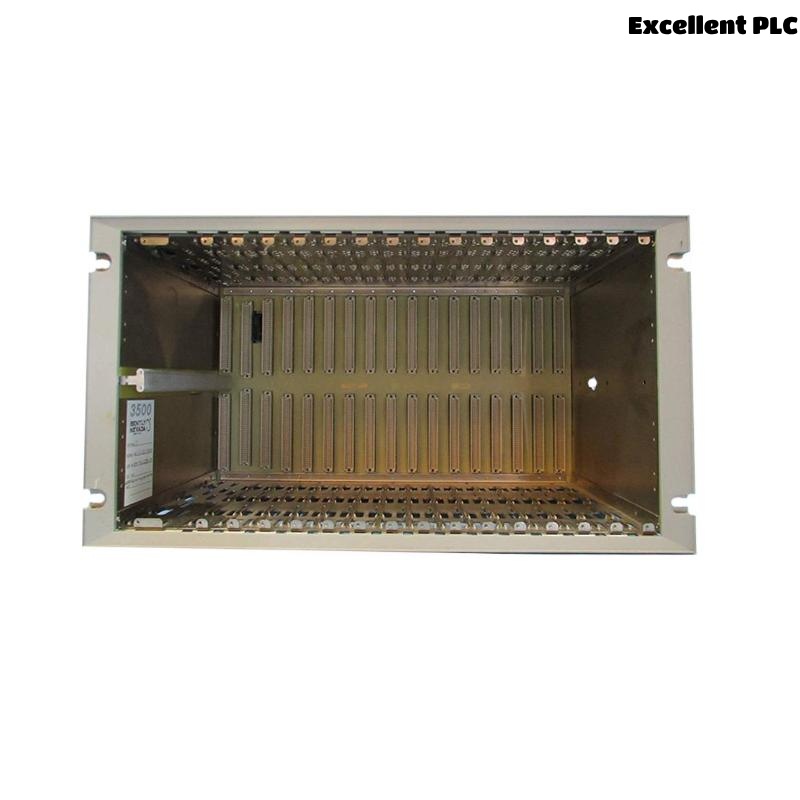

The Bently Nevada 3500/05-01-01-00-00-00 is a robust and versatile system rack designed to house multiple modules of the 3500 series monitoring system. This 19-inch rack accommodates up to 14 modules, providing a scalable and organized platform for vibration monitoring, machinery protection, and condition-based maintenance applications.

Built to industrial standards, the 3500/05 system rack offers secure module mounting, optimal ventilation, and easy access for maintenance. It is engineered to integrate seamlessly with the Bently Nevada 3500 monitoring system components, ensuring consistent communication and power supply to all installed modules. The rack plays a critical role in providing a reliable infrastructure for the early detection of machinery faults, helping to reduce downtime and prevent costly failures.

Technical Specifications

| Parameter | Specification |

|---|---|

| Model Name | 3500/05 System Rack |

| Order Code | 3500/05-01-01-00-00-00 |

| Brand | Bently Nevada |

| Rack Size | 19-inch (14 module slots) |

| Weight | 4.5 kg |

| Material | Aluminum and steel |

| Mounting Type | Standard 19-inch rack mount |

| Cooling | Passive ventilation |

| Power Distribution | Integrated power bus for modules |

| Dimensions | Please contact supplier for precise dimensions |

| Operating Temperature | -20°C to +60°C |

| Compliance | Meets industrial safety and EMI standards |

Applications

The 3500/05 system rack is widely used in:

-

Turbomachinery Monitoring

Hosting vibration and shaft position monitoring modules for turbines and compressors. -

Rotating Equipment Protection

Integrating condition monitoring modules to protect motors, pumps, and generators. -

Power Plants

Centralized rack solutions for plant-wide machinery monitoring. -

Oil & Gas Facilities

Monitoring critical rotating machinery in upstream and downstream operations. -

Manufacturing Plants

Industrial machinery condition monitoring for predictive maintenance. -

Pulp & Paper Industry

Integration of vibration and protection modules to improve operational reliability.

Advantages

-

High Module Capacity

Supports up to 14 modules, enabling extensive system expansion and customization. -

Standard Rack Size

Compatible with industry-standard 19-inch cabinets for easy integration. -

Robust Construction

Durable aluminum and steel design provides mechanical protection and longevity. -

Optimized Cooling

Passive ventilation ensures heat dissipation without additional power consumption. -

Simplified Wiring

Integrated power bus reduces cable clutter and improves system reliability. -

Ease of Maintenance

Modular design allows quick replacement and servicing of individual components.

Frequently Asked Questions (FAQ)

Q1: How many modules can the 3500/05 rack accommodate?

A1: It can accommodate up to 14 modules.

Q2: What are the physical dimensions of the rack?

A2: It is a standard 19-inch rack; detailed dimensions can be obtained from the supplier.

Q3: What is the weight of the rack?

A3: Approximately 4.5 kg.

Q4: Is the rack compatible with all 3500 series modules?

A4: Yes, it is designed to house all standard 3500 series modules.

Q5: How is the rack cooled?

A5: It uses passive ventilation to dissipate heat.

Q6: Can the rack be mounted in standard server cabinets?

A6: Yes, it is compatible with standard 19-inch cabinets.

Q7: Does the rack provide power distribution for the modules?

A7: Yes, it has an integrated power bus to supply power to installed modules.

Q8: What materials are used for the rack construction?

A8: Aluminum and steel, providing durability and mechanical strength.

Q9: What is the operating temperature range?

A9: It operates reliably from -20°C to +60°C.

Q10: Does the rack meet any industrial standards?

A10: Yes, it meets relevant safety and EMI standards.

Related Models (Same Series or Functionality)

| Model | Description | Function | Weight | Dimensions |

|---|---|---|---|---|

| 3500/01 | 7-slot system rack | Smaller rack for fewer modules | 3.0 kg | Standard 19-inch |

| 3500/02 | 10-slot system rack | Medium capacity rack | 3.8 kg | Standard 19-inch |

| 3500/03 | 5-slot system rack | Compact rack for limited modules | 2.5 kg | Standard 19-inch |

| 3500/04 | 8-slot system rack | Mid-sized rack | 3.2 kg | Standard 19-inch |

| 3500/06 | 16-slot system rack | Large capacity rack | 5.0 kg | Standard 19-inch |

| 3500/07 | Specialized rack for harsh environments | Enhanced protection | 6.0 kg | Standard 19-inch |

Popular Bently Nevada Models (Same Brand)

| Model | Description | Function | Weight | Dimensions |

|---|---|---|---|---|

| 3500/25 | 3300 XL vibration monitor | Machine vibration analysis | 1.2 kg | Compact size |

| 3500/55 | 3500/55 protective relay | Machinery protection | 1.5 kg | Modular design |

| 3500/32 | 3500/32 proximity probe | Shaft position monitoring | 0.4 kg | Small form factor |

| 3500/40 | 3500/40 vibration monitor | Advanced vibration analysis | 1.3 kg | Modular design |

| 3500/60 | 3500/60 keyphasor | Speed and phase reference | 0.5 kg | Compact size |

| 3500/90 | 3500/90 processor module | Central processing unit | 2.0 kg | Rack-mounted |

Excellent PLC

Excellent PLC