| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

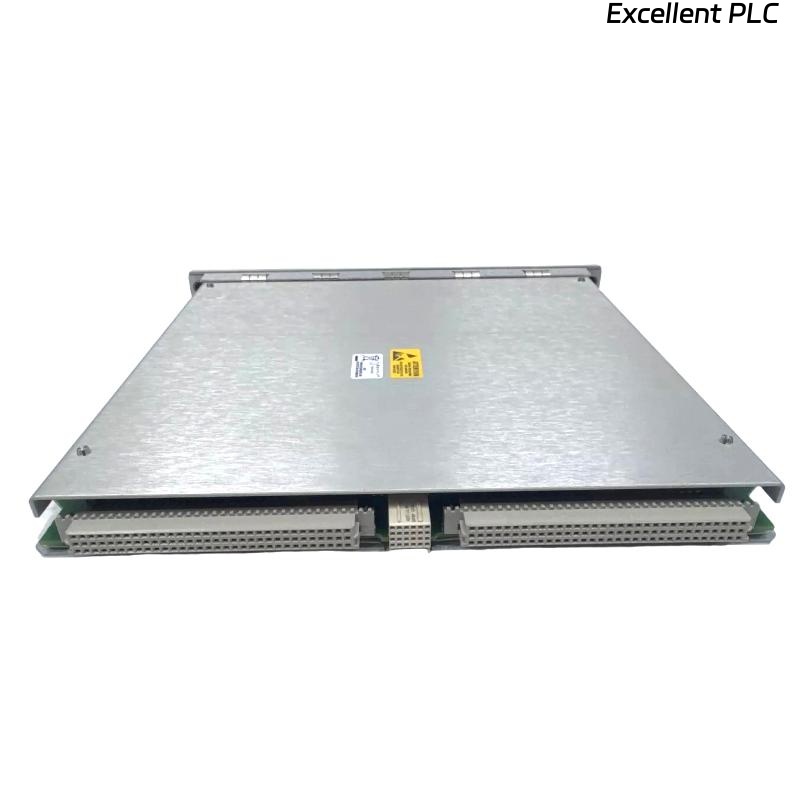

The Bently Nevada 3500/22 138607-01 Transient Data Interface Module is a specialized module within the 3500 Series machinery protection system designed to capture and process transient events from machinery vibration and operational signals. This module enhances the capability of the 3500 system by providing high-resolution transient data acquisition, allowing detailed analysis of machinery conditions during abnormal events such as impacts, looseness, or sudden faults. Engineered for industrial environments, the 3500/22 module supports improved diagnostics and predictive maintenance by enabling more accurate detection and characterization of transient phenomena. Its robust design ensures dependable operation in power plants, petrochemical facilities, and other critical industrial settings.

Product Specifications

| Specification | Details |

|---|---|

| Model Number | 3500/22 138607-01 |

| Module Type | Transient Data Interface Module |

| Signal Type | Vibration and transient event data |

| Sampling Rate | High-speed sampling capability (up to several kHz) |

| Data Resolution | High resolution, suitable for transient analysis |

| Power Consumption | Approximately 4 W |

| Operating Temperature | -40°C to +70°C |

| Storage Temperature | -55°C to +85°C |

| Relative Humidity | 5% to 95% (non-condensing) |

| Communication Interface | Backplane connector |

| Dimensions (HxWxD) | 241.3 x 24.4 x 241.8 mm |

| Weight | 0.91 kg |

| Certifications | CE, UL, CSA |

Applications

The 3500/22 Transient Data Interface Module is essential for advanced machinery condition monitoring, including:

-

Capturing and analyzing transient vibration events such as impacts and sudden anomalies

-

Enhancing machinery diagnostics in power generation turbines and generators

-

Monitoring rotating equipment in petrochemical and chemical plants for early fault detection

-

Supporting predictive maintenance programs by providing detailed event data

-

Improving overall reliability and uptime through better transient event analysis

-

Integration within 3500 Series racks for comprehensive machinery protection

This module enables detailed transient data acquisition that supplements continuous vibration monitoring to provide a complete picture of machine health.

Product Advantages

-

High-Speed Sampling: Capable of capturing transient events with excellent time resolution, enabling precise diagnostics.

-

Enhanced Data Quality: Provides high-resolution transient data, improving the accuracy of fault detection and analysis.

-

Robust and Reliable: Designed for harsh industrial environments with wide operating temperature and humidity ranges.

-

Seamless Integration: Fits into the 3500 Series rack system and interfaces efficiently with other monitoring modules.

-

Low Power Consumption: Efficient design reduces energy use while maintaining high performance.

-

Certified Safety and Compliance: Meets CE, UL, and CSA standards, ensuring safe and reliable operation.

-

Supports Predictive Maintenance: Enables early detection of machinery faults through detailed transient event data.

FAQ

-

What type of data does the 3500/22 module capture?

It captures transient vibration and operational event data for detailed analysis. -

What is the sampling rate of this module?

It supports high-speed sampling up to several kilohertz to capture fast transient events. -

Can the module be used to detect machinery impacts and looseness?

Yes, it is specifically designed to analyze transient phenomena such as impacts and looseness. -

How does this module integrate with other 3500 Series components?

It connects via the backplane connector within the 3500 rack system. -

What is the power consumption of the module?

Approximately 4 watts under normal operation. -

What operating temperature range does it support?

From -40°C to +70°C. -

Does the module provide real-time transient data?

Yes, it captures and processes transient data in real-time for immediate analysis. -

Is the module suitable for hazardous or harsh environments?

It is designed for harsh industrial environments but should be installed according to site safety standards. -

What certifications does this module have?

CE, UL, and CSA certifications. -

Does the module support remote diagnostics?

Remote diagnostics are handled through the 3500 system software, not directly by the module.

Related Models from the Same Series

| Model Number | Description | Key Feature |

|---|---|---|

| 3500/10 133263-01 | Interface Module | Signal conditioning |

| 3500/20 125744-02 | Rack Interface Module | Signal routing |

| 3500/15 133292-01 | AC/DC Power Supply Module | Power conversion |

| 3500/16 133295-01 | DC Power Supply Module | DC input power |

| 3500/30 133380-01 | Display Module | Local user interface |

| 3500/25 133377-01 | Expansion Module | Additional channel support |

Popular Models from Bently Nevada Brand

| Model Number | Description | Application |

|---|---|---|

| 3500/45 133450-01 | Proximitor Sensor | Proximity sensing |

| 2300 125863-01 | Portable Vibration Monitor | Field diagnostics |

| 7300 128047-01 | Machinery Protection System | Continuous machinery protection |

| 1490 132201-01 | Wireless Vibration Sensor | Remote monitoring |

| 3300 XL | High Precision Vibration Monitor | Advanced vibration analysis |

| 3500/22 133340-01 | Speed and Phase Monitor Module | Rotational speed monitoring |

Excellent PLC

Excellent PLC