| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

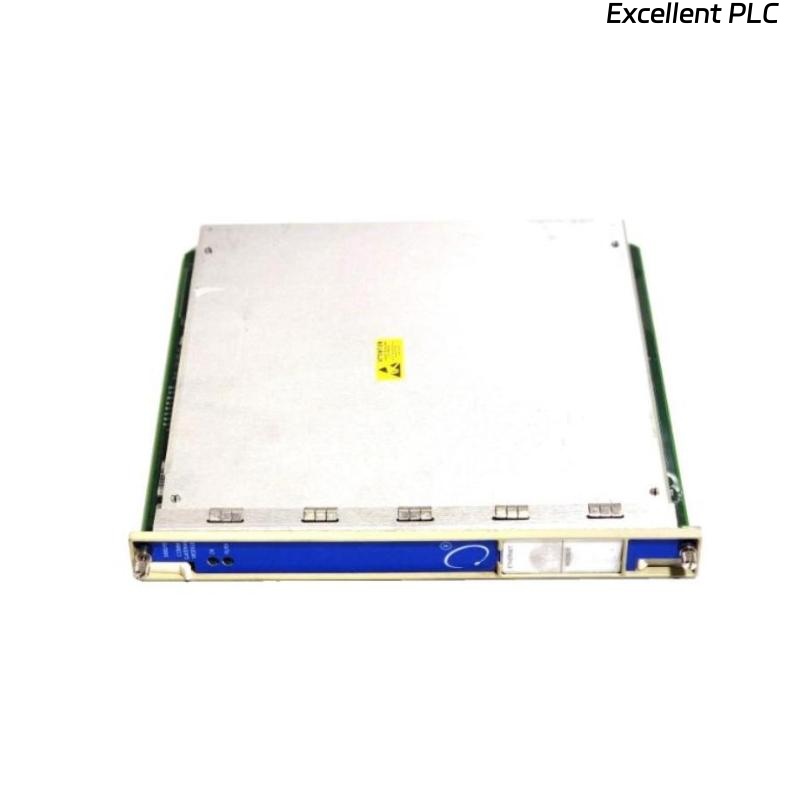

The Bently Nevada 3500/22 146031-02 Transient Data Interface Module (TDI) is a key communication module for the 3500 Machinery Protection System. It merges the functions of the 3500/20 Rack Interface Module (RIM) with an integrated communication processor, enabling high-speed transfer of both static and transient data to external software platforms such as System 1. Installed in Slot 1 of the rack, the TDI collects real-time information from all monitoring modules, processes event triggers, and sends detailed waveform and status data over Ethernet or fiber-optic links. With an optional Channel Enabling Disk, it can capture detailed pre- and post-event transient waveforms for advanced diagnostics.

Product Parameters

| Parameter | Specification |

|---|---|

| Part Number | 146031-02 |

| Series | 3500 |

| Module Type | Transient Data Interface Module |

| Slot Position | Slot 1 (adjacent to power supply) |

| Power Consumption | Approx. 10.5 W |

| Input Signal Range | –10 V DC to +10 V DC |

| Ethernet Interface | 10Base-T / 100Base-TX (copper) or 100Base-FX (fiber) |

| Operating Temperature | –30 °C to +65 °C |

| Storage Temperature | –40 °C to +85 °C |

| Relative Humidity | 0% to 95% non-condensing |

| Front Panel Interface | USB-B port |

| Indicators | OK, TX/RX, TM, CONFIG OK LEDs |

| Dimensions (W × H × D) | 241.3 x 24.4 x 241.8 mm |

| Weight | 0.91 kg |

| Mounting | 3500 rack slot |

Product Applications

The 3500/22 146031-02 TDI is widely deployed in critical rotating machinery protection and condition monitoring systems. Its key applications include:

-

Data acquisition for machinery diagnostics: Capturing and transferring both static parameters and high-resolution transient waveforms.

-

Integration with predictive maintenance software: Seamless connection with Bently Nevada System 1 for real-time analysis.

-

Transient event analysis: Monitoring startups, shutdowns, load changes, and trips.

-

Redundancy and fault comparison: In Triple Modular Redundant (TMR) configurations, comparing monitor outputs for fault detection.

-

Remote rack configuration and monitoring: Securely allowing or locking configuration changes via RUN/PROGRAM modes.

Product Advantages

-

Two-in-one integration – Combines RIM and communication processor in a single module, reducing hardware count.

-

Non-critical to protection path – Failure does not disable protective trip functions, ensuring operational safety.

-

Multiple network options – Supports both copper Ethernet and fiber-optic connections for flexible plant integration.

-

Advanced transient capture – Optional enabling disk allows high-resolution waveform recording before and after alarms.

-

Environmental robustness – Designed for industrial conditions with wide temperature and humidity tolerances.

-

Clear status feedback – LED indicators and OK relay provide immediate health and communication status.

FAQ

-

What is the primary role of the TDI in the 3500 system?

It serves as both the rack interface and the data communications processor, collecting and transmitting monitoring data to external systems. -

Can the TDI operate without an enabling disk?

Yes, but without it, transient waveform capture is not available—only static data is transmitted. -

How does the TDI handle communication failures?

Loss of communication is indicated by LED status changes and can be logged in the system for troubleshooting, without affecting protection. -

What slot in the rack is the TDI installed in?

It must be installed in Slot 1, directly next to the power supply module. -

Does the TDI process data from all rack modules?

Yes, it gathers information from all installed monitors and I/O modules. -

Can the TDI be used in TMR configurations?

Yes, it compares data from three redundant monitors to identify and isolate faults. -

What communication protocols does the TDI support?

It uses proprietary Bently Nevada protocols over Ethernet or fiber, compatible with System 1 software. -

How is rack configuration controlled through the TDI?

A physical keylock switch sets RUN or PROGRAM mode, allowing or preventing configuration changes. -

What types of data can be collected?

Static measurements, alarm statuses, and transient waveform data (when enabled). -

Does the TDI require specific monitor module versions?

Yes, it works best with M-series monitors for full transient capture capability.

Recommended Same Series / Related Models

| Model / Part Number | Description |

|---|---|

| 3500/20 | Rack Interface Module (RIM), predecessor to TDI |

| 3500/22M | Transient Data Interface Module, M-series compatible |

| 3500/22-01 | TDI variant with Ethernet copper interface |

| 3500/15 | Power Supply Module for 3500 system |

| 3500/40M | Proximitor® Monitor Module |

| 3500/42M | Velocity & Acceleration Monitor Module |

Recommended Other Popular Bently Nevada Models

| Model / Part Number | Description |

|---|---|

| 3500/32M | 4-Channel Relay Module |

| 3500/60 | Temperature Monitor |

| 3500/61 | Temperature I/O Module |

| 3500/65 | RTD / Thermocouple Monitor |

| 3300 XL Proximitor | Proximity Transducer for shaft vibration monitoring |

| 3500/92 | Communication Gateway Module |

Excellent PLC

Excellent PLC