| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

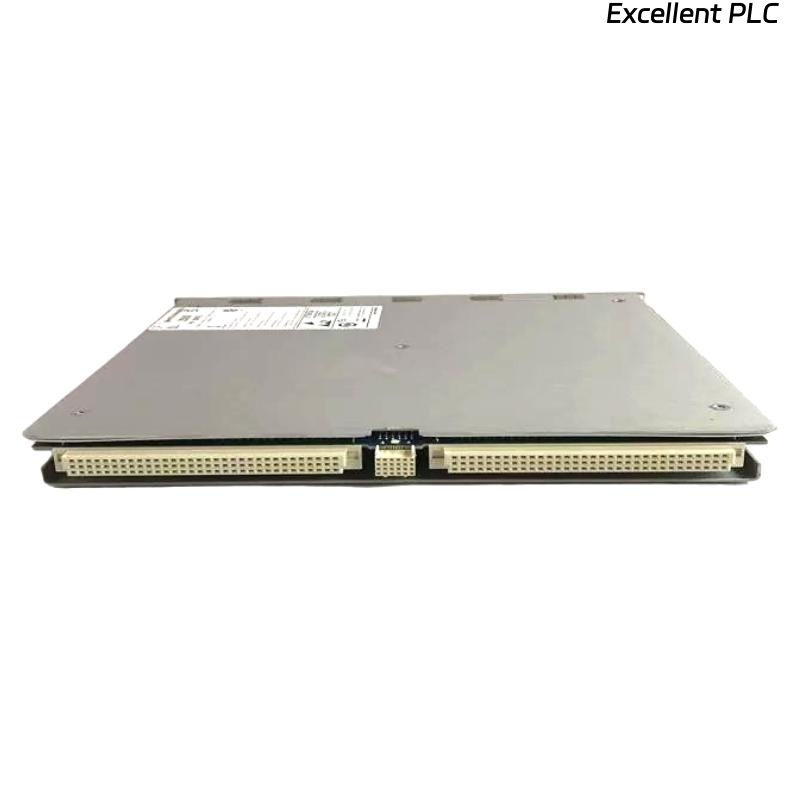

The Bently Nevada 3500/22 288055-01+146031-02 Transient Data Interface (TDI) Module is a high-performance monitoring component within the 3500 Machinery Protection System. It acts as the central communications processor, combining the functionality of the System Monitor and the Interface Module into a single unit. This TDI module handles the acquisition, processing, and transfer of transient and steady-state machine condition data to external systems, such as System 1 Condition Monitoring software.

It is engineered for high reliability in industrial environments, supporting multiple communication protocols and providing advanced transient data capture to ensure accurate diagnostics during abnormal machinery events. Its robust design ensures precise synchronization, event logging, and continuous machinery protection, making it an essential element in critical turbomachinery monitoring applications.

Product Specifications

| Parameter | Description |

|---|---|

| Model Number | 3500/22 288055-01 + 146031-02 |

| Function | Transient Data Interface (TDI) for Bently Nevada 3500 System |

| Communication Protocols | Ethernet, Modbus TCP/IP, Serial Modbus, Proprietary TCP/IP |

| Input Channels | Accepts dynamic and static data from all 3500 rack modules |

| Data Capture | Transient and steady-state machinery condition data |

| Sampling Rate | Up to 4 kHz per channel (dependent on module configuration) |

| Data Storage | Internal buffer for transient data retention |

| Power Supply | 18 to 36 VDC (supplied from rack power) |

| Operating Temperature | –30°C to +65°C |

| Relative Humidity | 0% to 95% non-condensing |

| Mounting | Installed in the leftmost slot of the 3500 rack |

| Dimensions (H × W × D) | 241.3 x 24.4 x 241.8 mm |

| Weight | 0.91 kg |

| Compatibility | Fully compatible with Bently Nevada System 1 software |

| Approvals | CE, CSA, ATEX, IECEx for hazardous locations |

Product Applications

The 3500/22 TDI module is widely deployed in industrial sectors where precision machinery monitoring is mission-critical. Typical applications include:

-

Turbomachinery Protection — Gas turbines, steam turbines, compressors, and generators.

-

Condition Monitoring — Real-time health analysis of rotating equipment.

-

Event & Alarm Management — Captures transient data during machinery trips, overspeed, or vibration anomalies.

-

Integration with Plant Control Systems — Seamless communication via Ethernet or Modbus for DCS/SCADA integration.

-

Predictive Maintenance — Supports trend analysis and diagnostics to prevent unplanned outages.

-

High-Speed Transient Capture — Essential for root cause analysis in high-impact industrial incidents.

Product Advantages

-

High Integration — Combines system monitoring and communications in one module, reducing rack space usage.

-

Advanced Data Capture — Records detailed transient data for accurate fault analysis.

-

Multi-Protocol Support — Facilitates integration with diverse plant control and diagnostic systems.

-

Real-Time Performance — High-speed sampling ensures no critical event data is missed.

-

Rugged Industrial Design — Operates reliably in harsh temperature and vibration conditions.

-

Seamless Compatibility — Fully interoperable with all 3500 rack modules and System 1 software.

-

Secure Communications — Designed to protect data integrity in networked environments.

FAQ

-

What is the difference between transient data and steady-state data in the 3500/22 TDI module?

Transient data is high-frequency, time-synchronized waveform information captured around events, while steady-state data represents slower-changing parameters like vibration amplitude or temperature. -

Can the 3500/22 288055-01+146031-02 module operate independently outside the 3500 rack system?

No, the module requires integration within the 3500 rack to interface with monitoring modules and power supply. -

What communication protocols are supported by this Transient Data Interface Module?

It supports Ethernet TCP/IP, Modbus TCP/IP, serial Modbus, and proprietary Bently Nevada protocols. -

Does the module provide local storage for transient waveform data?

Yes, it includes an internal buffer that temporarily stores transient data until it can be transmitted to external systems. -

How is time synchronization achieved across multiple 3500 racks?

Synchronization is maintained using network time protocols to align event timestamps for accurate correlation. -

Is remote firmware updating supported on this module?

Yes, firmware updates can be performed remotely via the Ethernet interface with appropriate security measures. -

Does the TDI module support redundant communication paths?

Yes, dual Ethernet ports allow configuration for redundant network communication to enhance reliability. -

What types of diagnostics and health monitoring information are available from the module?

The module provides status of module health, communication links, event logs, and configuration validation indicators. -

How does the module handle loss or interruption of network communication?

It continues to buffer data locally and transmits it when communication is restored, preventing data loss. -

What is the maximum duration of transient data capture supported by the module?

The capture length depends on configuration and memory allocation but typically supports several seconds of high-resolution waveform per channel.

Related Models (Same Series or Functional Category)

| Model | Description |

|---|---|

| 3500/22M 288055-01 | TDI Module with Modbus capability |

| 3500/20 | Rack Interface Module |

| 3500/25 | Enhanced Keyphasor Module |

| 3500/32M | 4-Channel Relay Module |

| 3500/42M | Proximitor/Seismic Monitor |

| 3500/94 | VGA Display Interface Module |

Popular Bently Nevada Models

| Model | Description |

|---|---|

| 3300 XL 5mm Proximitor | Proximity transducer for vibration measurement |

| 330103-00-05-10-02-05 | 8 mm Proximitor sensor |

| 3500/15 | Power Supply Module |

| 3500/40M | Proximitor/Seismic Monitor |

| 3500/50 | Tachometer Module |

| 3500/60 | Temperature Monitor |

Excellent PLC

Excellent PLC