| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

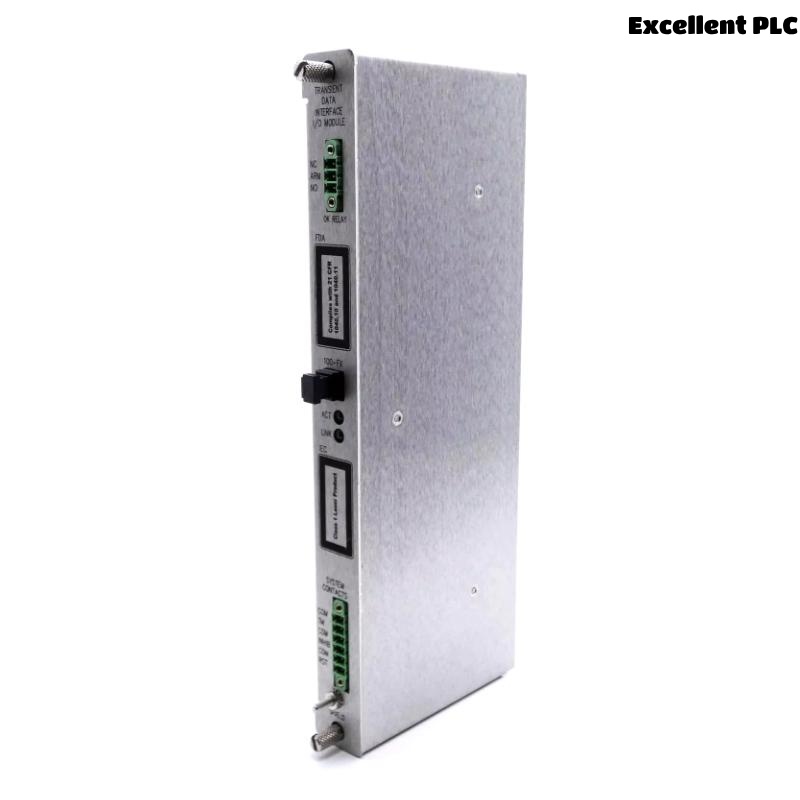

The Bently Nevada 3500/22M 146031-02 100Base-FX Fiber Optic I/O Module is a high-performance communication interface module designed for use within the Bently Nevada 3500 Series machinery protection and condition monitoring system. This particular variant is equipped with a 100Base-FX fiber optic communication interface, enabling high-speed, noise-resistant data transfer between the 3500 rack and external monitoring or control systems.

By using fiber optic transmission, the 3500/22M 146031-02 ensures reliable, long-distance communication even in electrically noisy industrial environments. It plays a pivotal role in transmitting high-resolution transient vibration data—critical for early fault detection—especially in applications where electromagnetic interference (EMI) can compromise traditional copper-based links.

This module is ideal for demanding industrial environments such as power generation plants, offshore oil platforms, petrochemical facilities, and heavy manufacturing, where high-speed data integrity and equipment protection are paramount.

Product Specifications

| Specification | Details |

|---|---|

| Model Number | 3500/22M 146031-02 |

| Function | Transient Data Interface I/O with Fiber Optic |

| Communication Type | 100Base-FX (Fiber Optic, Multimode ST Connector) |

| Compatible System | Bently Nevada 3500 Series |

| Signal Type | Transient vibration data |

| Data Acquisition | High-speed event capture |

| Power Supply | 24 V DC |

| Power Consumption | Approx. 5 W |

| Dimensions (W x H x D) | 241.3 x 24.4 x 99.1 mm |

| Weight | 0.2 kg |

| Operating Temperature | -20 °C to +70 °C |

| Storage Temperature | -40 °C to +85 °C |

| Humidity | Up to 95%, non-condensing |

| Connectors | ST-style fiber optic connectors |

| Certifications | CE, UL, ATEX (if applicable) |

Product Applications

The 3500/22M 146031-02 module is widely deployed in high-noise or long-distance monitoring environments, supporting both machinery protection and advanced diagnostics:

-

Power Generation Plants

For monitoring turbines, boilers, and generators where EMI protection is crucial. -

Oil & Gas Exploration and Refining

Used on offshore rigs, pipelines, and compressors to ensure data integrity over fiber links. -

Petrochemical Processing

Enables fast, accurate diagnostics in corrosive and high-temperature environments. -

Mining and Metallurgy

Ideal for vibration signal capture from conveyors, crushers, and mills in remote locations. -

Marine and Naval Applications

Ensures vibration monitoring of shipboard equipment under harsh maritime conditions. -

Industrial Automation and Robotics

Provides real-time, interference-free monitoring of fast-moving automated systems.

Product Advantages

-

Fiber Optic Communication

Immune to electrical noise, ideal for EMI-heavy environments and long-distance data transmission. -

High-Speed Data Transfer

100Base-FX allows for rapid and accurate transmission of vibration data to monitoring systems. -

Early Fault Detection

Captures transient mechanical events like rubbing, imbalance, and bearing wear at early stages. -

Rugged Industrial Design

Built to endure harsh conditions including temperature extremes and high humidity. -

System Compatibility

Fully compatible with the Bently Nevada 3500 Series rack and protection modules. -

Energy Efficient

Low power consumption while providing high-speed, high-integrity data transfer. -

Enhanced Safety

Certified for use in potentially hazardous environments (ATEX where applicable). -

Space-Saving Format

Compact design for seamless integration into existing 3500 system racks. -

Diagnostic Reliability

Ensures the delivery of clean, undistorted transient data critical for predictive maintenance. -

Field Proven

Trusted across industries for dependable operation and long service life.

Frequently Asked Questions (FAQ)

-

What is the primary role of the 3500/22M 146031-02 module?

It transmits transient vibration data via fiber optics from the Bently Nevada 3500 system to external systems. -

What type of fiber optic connection does this module use?

It uses 100Base-FX multimode ST-style fiber optic connectors for communication. -

Why choose fiber optic over traditional copper interfaces?

Fiber is immune to EMI, supports longer distances, and offers greater data integrity in industrial environments. -

What equipment can this module help monitor?

Turbines, compressors, motors, pumps, and other rotating machinery requiring high-speed diagnostics. -

Is this module compatible with all 3500 racks?

Yes, it is fully compatible with all standard 3500 monitoring system racks. -

How does it support predictive maintenance strategies?

It provides high-resolution data on transient events that are critical to diagnosing developing mechanical faults. -

Can the fiber optic link be extended over long distances?

Yes, 100Base-FX supports longer distances than copper—typically up to 2 km with multimode fiber. -

Is any special software required to use this module?

It integrates with Bently Nevada System 1 and other compatible vibration monitoring platforms. -

What safety certifications does it meet?

It meets CE, UL, and optionally ATEX standards for use in hazardous environments. -

Does this module require regular calibration or maintenance?

It is low-maintenance; routine inspection of fiber links and basic cleaning is typically sufficient.

Related Models from the Same Series

| Model Number | Description | Key Feature |

|---|---|---|

| 3500/22-01-01-00 | Standard Transient Interface Module | Copper-based communication |

| 3500/22-01-01-02 | Transient Interface with diagnostics | Event monitoring with enhanced analysis |

| 3500/25-01-00-00 | Speed/Phase Module | Phase reference and rotational speed |

| 3500/23-01-00-00 | Vibration Processing Module | Signal conditioning and measurement |

| 3500/32-00-00-00 | Display Module | Operator interface for live readings |

| 3500/20-01-01-00 | Proximitor Sensor Interface | Proximity sensor integration |

Popular Bently Nevada Models from the Same Brand

| Model Number | Description | Key Feature |

|---|---|---|

| 3500/05-01-05-00 | System Rack with Power Supply | Central mounting unit for modules |

| 3500/62-01-00-00 | Process Variable Interface | Integration of pressure, flow, temp data |

| 3500/42-01-00-00 | Proximitor Monitor | Displacement and gap monitoring |

| 3500/15-01-00-00 | Power Supply Module | Redundant power supply for 3500 system |

| 3300 XL | Proximitor Sensor | Rugged proximity probe system |

| 7200 Series | Legacy Machinery Monitoring System | Proven condition monitoring platform |

Excellent PLC

Excellent PLC