| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

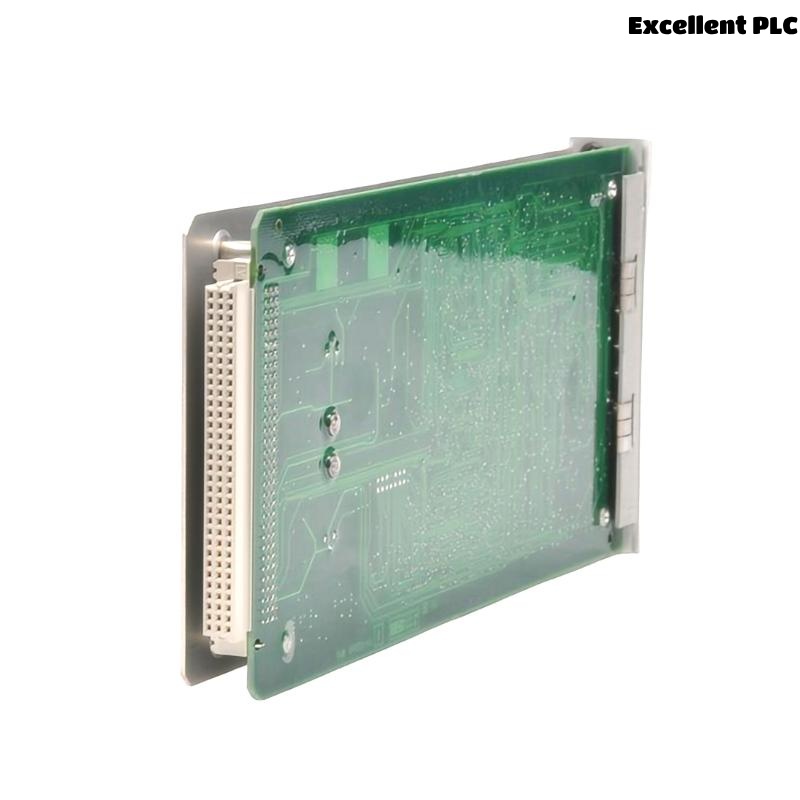

The Bently Nevada 3500/25-01-01-00 Enhanced Keyphasor Module is a vital component of the renowned 3500 Series machinery protection system. This module serves as the primary phase reference source for monitoring rotating machinery, providing precise timing signals needed to analyze shaft vibration and position.

This Keyphasor module processes input from magnetic pickups or proximity probes to generate a clean, TTL-compatible pulse that marks the angular position of the shaft. These pulses synchronize vibration data acquisition and enable advanced diagnostic tools such as orbit plots, Bode plots, and rotor balancing.

The “Enhanced” designation reflects improvements in signal conditioning, noise immunity, and integration capability, making it well suited for high-speed turbines, compressors, and motors in demanding industrial environments.

Technical Specifications

| Parameter | Specification |

|---|---|

| Product Name | Enhanced Keyphasor Module |

| Model Number | 3500/25-01-01-00 |

| Function | Generates shaft phase reference pulses for machinery protection |

| Compatible Sensors | Magnetic pickups, proximity probes (e.g., Bently Nevada 3300 XL) |

| Signal Output | TTL-compatible square wave |

| Pulse Frequency Range | 1 Hz to 20 kHz |

| Pulse Width | 10 µs to 500 µs |

| Power Supply | Powered via 3500 rack backplane |

| Mounting | Plug-in module for 3500 Series rack |

| Operating Temperature | -30°C to +65°C |

| Storage Temperature | -40°C to +85°C |

| Humidity | 5%–95% relative humidity, non-condensing |

| Dimensions (W × H × D) | 119.9 x 24.4 x 256.5 mm |

| Weight | 0.34 kg |

| Certifications | CE, UL, CSA, RoHS compliant |

Applications

The 3500/25-01-01-00 Enhanced Keyphasor Module is used in a broad range of industrial settings where reliable and accurate shaft phase referencing is crucial:

-

Gas and Steam Turbines

Provides phase reference pulses essential for turbine vibration analysis and condition monitoring. -

Compressors

Used in centrifugal and axial compressors to detect imbalance, misalignment, and surge. -

Electric Generators and Motors

Enables synchronous data acquisition for dynamic condition monitoring. -

Petrochemical and Refining Facilities

Supports predictive maintenance by delivering accurate phase data for critical rotating assets. -

Marine Propulsion Systems

Assists in rotor dynamic monitoring and balancing of marine engines. -

Power Plants

Integral part of machinery protection systems ensuring safe and efficient operation.

Product Advantages

-

Accurate Phase Reference Generation

Provides clean, reliable TTL pulses for precise shaft position tracking. -

Improved Noise Immunity

Enhanced signal conditioning reduces the impact of electromagnetic interference (EMI). -

Wide Frequency Range

Supports monitoring of low-speed to very high-speed rotating machinery. -

Seamless Integration

Designed to fit perfectly within the Bently Nevada 3500 Series rack system. -

Robust and Durable

Built to withstand harsh industrial environments, including temperature extremes and humidity. -

Minimal Maintenance

Solid-state design reduces failure points and the need for ongoing servicing. -

Comprehensive Compliance

Meets all relevant industry standards for safety and electromagnetic compatibility. -

Enables Advanced Diagnostics

Supports a range of diagnostic tools for rotor health assessment and machinery protection.

Frequently Asked Questions (FAQ)

1. What is the primary role of the 3500/25-01-01-00 module?

It generates the shaft phase reference pulse necessary for synchronizing vibration data acquisition.

2. Which sensors are compatible with this module?

It works with magnetic pickups and proximity probes like the Bently Nevada 3300 XL series.

3. Does this module output a digital or analog signal?

It outputs a TTL-compatible digital square wave signal.

4. What is the maximum frequency this module can handle?

It can handle pulse frequencies up to 20 kHz.

5. How is the module powered?

The module is powered through the 3500 Series rack backplane; no external power is needed.

6. Can this module be installed in any slot of the 3500 rack?

No, it is designed to be installed specifically in the slot designated for Keyphasor modules.

7. What environmental conditions can the module operate in?

It operates within -30°C to +65°C and can tolerate up to 95% relative humidity non-condensing.

8. Is this module compatible with hazardous area installations?

It is compatible when used within certified Bently Nevada 3500 rack assemblies designed for hazardous environments.

9. Does it require calibration or adjustment after installation?

Typically, no manual calibration is required; setup is mainly sensor-dependent.

10. What differentiates this Enhanced Keyphasor module from earlier versions?

It offers improved noise rejection, better signal conditioning, and enhanced compatibility with advanced monitoring systems.

Related Models from the Same Series or Category

| Model | Part Number | Description |

|---|---|---|

| 3500/25 | 125800-01 | Enhanced Keyphasor Module (alternative version) |

| 3500/25 | 126398-01 | Enhanced Keyphasor Module with different configuration |

| 3500/25 | 149369-01 | Isolated Keyphasor I/O Module |

| 3500/25 | 135473-01 | Non-isolated Keyphasor I/O Module |

| 3500/50M | 3500/50M-01-01-00 | Tachometer and Speed Monitoring Module |

| 3500/22M | 288055-01 | Transient Data Interface Module |

Popular Bently Nevada Models in Similar Categories

| Model | Part Number | Function |

|---|---|---|

| 330130-040-00 | 330130-040-00 | Proximity Probe for vibration and phase measurements |

| 330180-91-00 | 330180-91-00 | Extension Cable for 3300 XL proximity transducers |

| 330500-02-00 | 330500-02-00 | Velocity Sensor for low-frequency vibration monitoring |

| 3500/15 | 3500/15-05-01-00 | Power Supply Module for 3500 Series |

| 3500/05 | 3500/05-01-01-00 | Rack Chassis for Bently Nevada 3500 modules |

| 3500/42M | 3500/42M-01-01-00 | Vibration and Position Monitoring Module |

Excellent PLC

Excellent PLC