| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

The Bently Nevada 3500/32 125712-01+125720-01 4 Channel Relay Module is an advanced relay interface designed for use in the Bently Nevada 3500 Machinery Protection System. This module provides four independent relay channels, enabling flexible alarm, trip, and shutdown control for critical machinery. It integrates seamlessly into the 3500 rack, receiving alarm signals from monitoring modules and activating its relays according to user-configured logic.

The 3500/32 supports a variety of relay types, including normally open (NO) and normally closed (NC) configurations, to meet different safety and control requirements. It is often deployed in turbine, compressor, pump, and generator protection systems, ensuring machinery safety in high-value industrial applications.

Product Parameters

| Parameter | Description |

|---|---|

| Module Type | 4 Channel Relay Module |

| Part Number | 125712-01 (Module), 125720-01 (I/O) |

| Number of Channels | 4 independent channels |

| Relay Type | Electromechanical |

| Relay Contact Configurations | Normally Open (NO) / Normally Closed (NC) |

| Relay Contact Ratings | 5 A @ 24 VDC / 120 VAC |

| Logic Configurations | Alarm, Danger, Trip, Latching/Non-Latching |

| Response Time | < 10 ms from alarm detection |

| Power Consumption | < 5 W |

| Operating Temperature | -30°C to +65°C |

| Humidity Range | 0–95% non-condensing |

| Rack Compatibility | Bently Nevada 3500 Rack |

| Dimensions | 241 x 24.4 x 242 mm |

| Weight | 0.7 kg |

Product Applications

The 3500/32 4 Channel Relay Module is widely used in critical industrial environments where immediate relay action is required upon detection of a fault condition.

Common applications include:

-

Turbomachinery Protection – Activating emergency shutdown sequences for gas/steam turbines.

-

Compressor Monitoring Systems – Triggering alarms and trips during excessive vibration or temperature rise.

-

Pump Protection – Preventing damage from dry-run, overheating, or cavitation events.

-

Generator Safety Systems – Automatic disconnection under hazardous operating conditions.

-

Industrial Automation Systems – Interfacing alarms with Distributed Control Systems (DCS) or PLCs.

Product Advantages

-

High Reliability – Designed for continuous operation in mission-critical industrial environments.

-

Fast Response – Millisecond-level reaction time ensures immediate shutdown during dangerous events.

-

Flexible Configuration – Each relay can be programmed for specific alarm or trip logic.

-

Robust Electrical Ratings – Supports both AC and DC loads with strong switching capacity.

-

Integration-Friendly – Fully compatible with 3500 system modules and industry-standard control systems.

-

Redundant Protection – Supports latching and non-latching modes for additional safety assurance.

FAQ

-

What types of relay contact configurations are available in the 3500/32 module?

The module supports both normally open (NO) and normally closed (NC) relay contact configurations, providing flexibility for different system designs. -

Can each relay channel be configured independently?

Yes, each of the four relay channels can be individually configured for alarm, danger, trip, or other custom logic. -

What is the maximum switching capacity for each relay contact?

Each relay contact can handle up to 5 A at 24 VDC or 120 VAC. -

Does the module support both latching and non-latching modes?

Yes, users can configure each relay to operate in latching or non-latching mode depending on application requirements. -

What is the typical relay activation time after receiving a signal?

The typical response time is less than 10 milliseconds from alarm detection to relay activation. -

Is the module hot-swappable within the 3500 rack?

No, due to safety considerations, the module should be replaced only when the rack is powered down. -

How is relay logic configured in the 3500/32 module?

Configuration is performed through the 3500 Configuration Software, where relay voting, alarm combinations, and fail-safe settings can be defined. -

Can the relays be used to control external devices directly?

Yes, the relays can switch power to external alarms, sirens, shutdown valves, or other devices within their rated capacity. -

What are the common failure modes for this module?

Failures may occur due to contact wear from excessive switching, electrical surges, or operating beyond specified limits. -

Does the module provide any self-diagnostic capability?

Yes, it includes built-in diagnostics to detect internal faults, relay coil failures, or communication issues with the rack.

Recommended Related Models (Same Series / Function)

| Model Number | Description |

|---|---|

| 3500/25 149369-01 | Enhanced Keyphasor Module |

| 3500/32 125720-01 | 4 Channel Relay I/O Module |

| 3500/42M 140734-02 | Proximitor/Seismic Monitor |

| 3500/92 136180-01 | Communication Gateway Module |

| 3500/33 149986-01 | 16-Channel Relay Module |

| 3500/50 133388-01 | Tachometer Module |

Popular Models from the Same Brand (Bently Nevada)

| Model Number | Description |

|---|---|

| 3500/15 125680-01 | Power Supply Module |

| 3500/20 125744-02 | Rack Interface Module |

| 3500/22M 288055-01 | Transient Data Interface |

| 3500/45 176449-04 | Position Monitor |

| 3500/46M 275268-01 | Hydro Monitor |

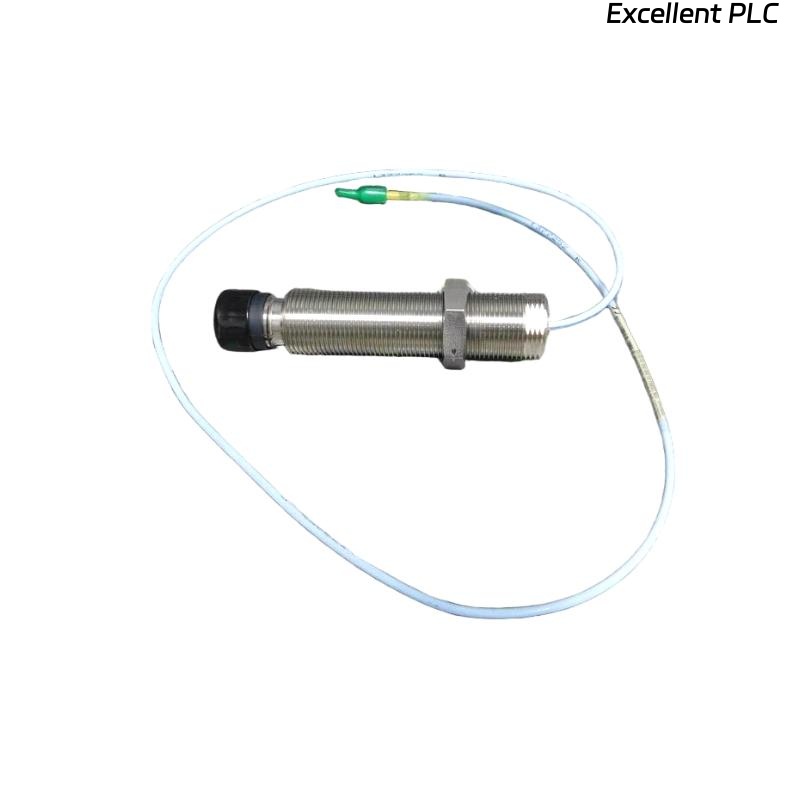

| 330104-00-05-10-02-00 | Proximity Probe |

Excellent PLC

Excellent PLC