| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

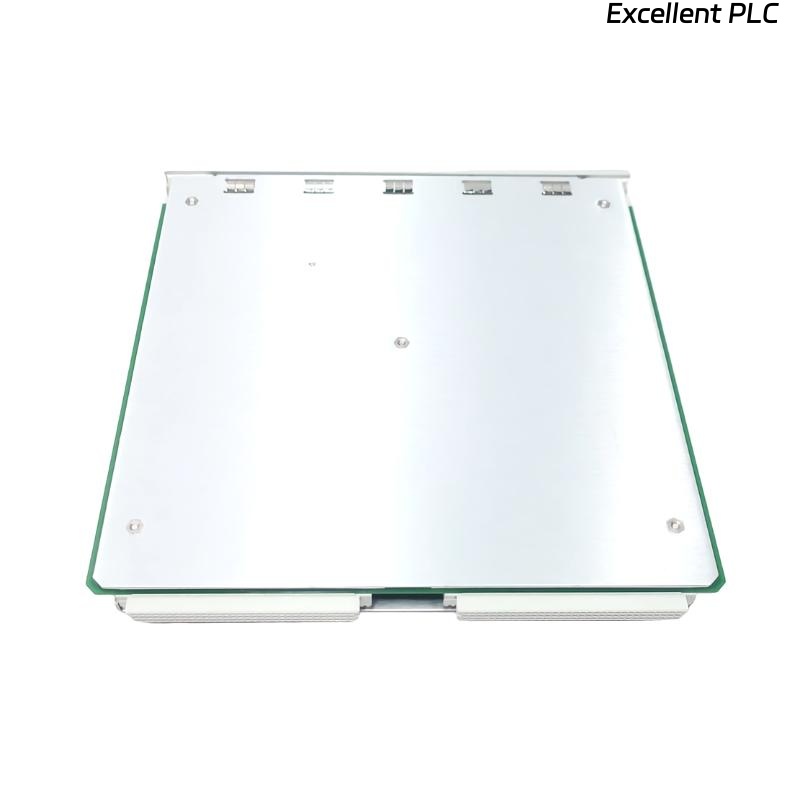

The Bently Nevada 3500/32 149986-02 4 Channel Relay Module is a highly reliable output module designed for use within the 3500 Machinery Protection System. It is engineered to provide four independent relay outputs, each of which can be individually configured to operate based on alarm conditions from any channel in the system. This design ensures flexible alarm management, redundancy, and fail-safe protection for critical machinery assets.

This relay module is commonly used in turbine, compressor, motor, and generator protection systems, where precise and dependable alarm actuation is essential. It operates in conjunction with the 3500 Rack, using its own I/O module and terminal blocks to provide isolated and configurable output switching for connected safety devices or annunciation systems.

Product Parameters

| Parameter | Description |

|---|---|

| Module Type | 4 Channel Relay Output Module |

| Part Number | 3500/32 149986-02 |

| Number of Relays | 4 independent Form C relay outputs |

| Relay Contact Rating | 5 A @ 30 Vdc or 250 Vac (resistive load) |

| Operating Voltage | 24 Vdc nominal (from rack power supply) |

| Relay Mode | Normally Energized (NE) or Normally De-energized (ND) |

| Logic Configuration | OR / AND logic from one or multiple channel alarms |

| Response Time | < 10 ms after alarm detection |

| Isolation | Galvanic isolation between relay outputs and system electronics |

| Operating Temperature | -30 °C to +65 °C |

| Storage Temperature | -40 °C to +85 °C |

| Humidity | 95% non-condensing |

| Mounting | 3500 rack slot-based |

| Dimensions | 241 x 24.4 x 242 mm |

| Weight | 0.7 kg |

Product Applications

The Bently Nevada 3500/32 149986-02 4 Channel Relay Module is widely applied in heavy industrial environments where mechanical assets require continuous monitoring and fast protection response. Typical applications include:

-

Turbomachinery (steam turbines, gas turbines) — Triggering trips, shutdowns, or alarms in the event of overspeed, vibration, or process parameter violations.

-

Compressors — Providing critical trip commands during surge, high vibration, or bearing temperature excursions.

-

Electric Motors and Generators — Activating protection circuits upon detection of faults to avoid equipment damage.

-

Pumps and Fans — Offering shutdown capabilities in response to severe process deviations.

-

Plant-wide Safety Systems — Integration with Distributed Control Systems (DCS) or Emergency Shutdown Systems (ESD) for coordinated protection.

Product Advantages

-

High Reliability — Designed for mission-critical operations with fast switching response and robust relay contacts.

-

Flexible Configuration — Supports a wide range of alarm logic combinations for custom protection schemes.

-

Redundant Capability — Can be configured in parallel with other modules for redundancy and fail-safe operation.

-

Electrical Isolation — Prevents cross-interference between relay outputs and system electronics, improving overall system stability.

-

Industry Proven — Part of the established 3500 Series platform used worldwide in demanding machinery protection applications.

-

Compact Rack Integration — Slot-based design allows easy installation and replacement without disturbing other modules.

FAQ

-

What is the relay contact rating for this module?

The relays are rated at 5 A at 30 Vdc or 250 Vac for resistive loads. -

Can each relay be assigned to different alarms?

Yes, each of the four relays can be individually mapped to alarms from any channel within the 3500 system. -

Does the module support both normally energized and normally de-energized modes?

Yes, relay operation can be configured for either mode to suit the safety philosophy of the installation. -

How fast does the relay respond to an alarm?

The module has a typical response time of less than 10 milliseconds after alarm detection. -

Is there galvanic isolation between the relays and the system?

Yes, the outputs are electrically isolated to avoid interference and ensure system integrity. -

Can relay logic be configured as AND or OR?

Yes, relay actuation logic supports both AND and OR configurations depending on application requirements. -

Does the module require a specific I/O terminal block?

Yes, it uses its own dedicated I/O module and terminal block compatible with the 3500 rack. -

Is the module hot-swappable?

No, it should only be inserted or removed with rack power off to avoid potential equipment damage. -

What is the operational temperature range?

The module can operate from -30 °C to +65 °C. -

Can the relays be tested without triggering actual trips?

Yes, the 3500 software allows relay test functions to verify wiring and logic without affecting plant operations.

Recommended Related Models (Same Series)

| Model Number | Description |

|---|---|

| 3500/32 125712-01 | 4 Channel Relay Module, standard version |

| 3500/32 149986-01 | 4 Channel Relay Module, enhanced version |

| 3500/33 149986-02 | 16 Channel Relay Module |

| 3500/34 149992-01 | TMR Relay Module |

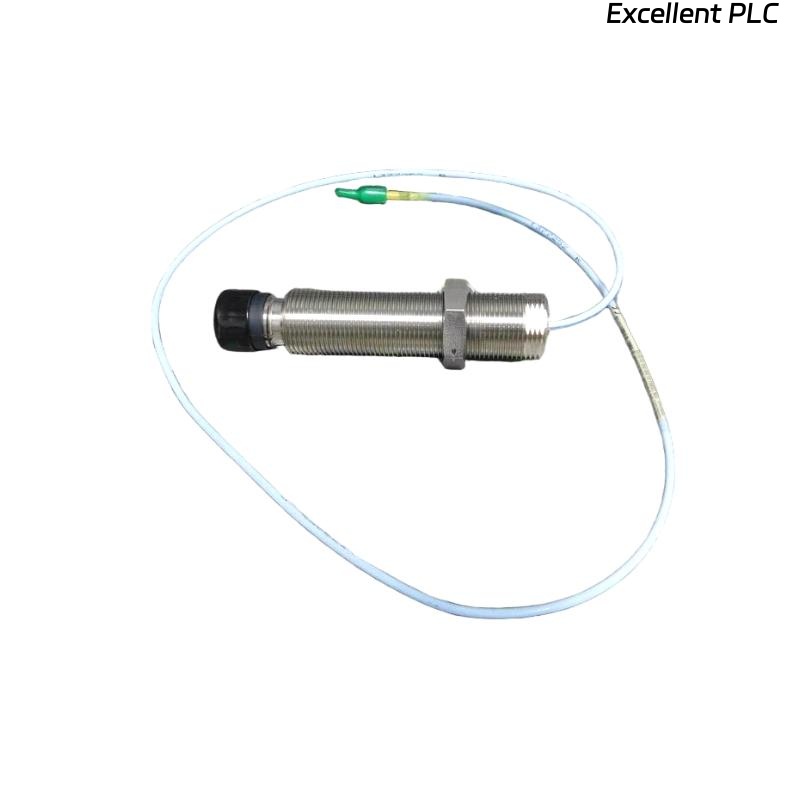

| 3500/42M 140734-02 | Proximitor/Seismic Monitor Module |

| 3500/50 133388-01 | Tachometer Module |

Popular Models from the Same Brand (Bently Nevada)

| Model Number | Description |

|---|---|

| 3500/22M 288055-01 | Transient Data Interface Module |

| 3500/42M 140734-02 | Proximitor/Seismic Monitor |

| 3500/92 136711-01 | Communication Gateway Module |

| 3500/50 133388-01 | Tachometer Module |

| 3500/53 133388-02 | Overspeed Detection Module |

| 3300/55 78492-01 | Dual Keyphasor Module |

Excellent PLC

Excellent PLC