| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

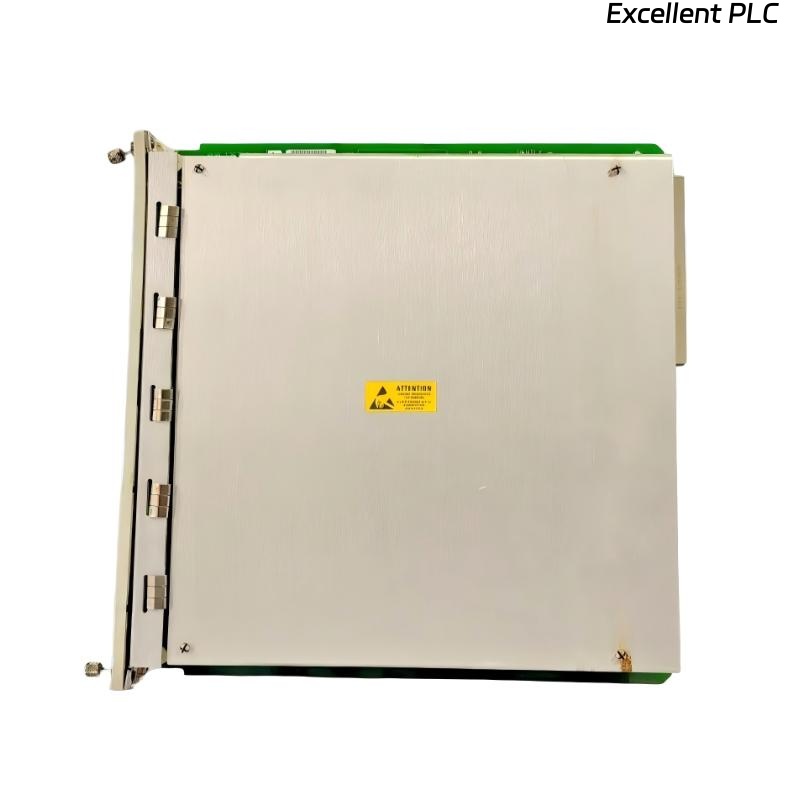

The Bently Nevada 3500/32M-01 4 Channel Relay Module is a high-performance relay module designed for integration within the 3500 Series Machinery Protection System. This module provides four independent relay outputs capable of supporting critical alarm and shutdown functions.

The 3500/32M-01 interfaces seamlessly with other 3500 Series modules, including vibration, proximity, and keyphasor sensors, converting monitored signals into reliable relay actions. Its robust industrial design ensures operation under high vibration, electrical noise, and temperature fluctuations, making it ideal for demanding industrial environments.

This module is widely used to trigger alarms, emergency shutdowns, and auxiliary control functions, ensuring operators receive fast and dependable notifications of abnormal machinery conditions.

Technical Specifications

| Parameter | Specification |

|---|---|

| Model Number | 3500/32M-01 |

| Module Type | 4 Channel Relay Module |

| System Compatibility | Bently Nevada 3500 Series |

| Number of Channels | 4 Independent Relays |

| Relay Type | SPDT (Single Pole Double Throw) |

| Contact Rating | 2 A at 30 V DC / 2 A at 250 V AC |

| Input Signal | TTL or dry contact from 3500 Series modules |

| Response Time | <10 ms typical |

| Operating Temperature Range | –20°C to +70°C |

| Power Consumption | 5 W typical |

| Isolation | 1500 V galvanic isolation between relays and module logic |

| Dimensions (L × W × H) | 241 x 24.4 x 242 mm |

| Weight | 0.7 kg |

| Mounting | Standard 3500 Series rack compatible |

Product Applications

The 3500/32M-01 4 Channel Relay Module is widely applied in machinery protection and industrial automation:

-

Turbine Systems: Relay outputs provide trips for overspeed, vibration, or phase faults.

-

Compressor Units: Trigger alarms or shutdowns in response to abnormal operating conditions.

-

Pumping Stations: Support emergency stops and alarm signaling for critical pumps.

-

Generator Protection: Monitor and signal abnormal conditions for protective actions.

-

Integrated Plant Control: Provides auxiliary control and interlock functions across industrial systems.

-

Process Automation: Enables relay outputs to control secondary protective measures for machinery.

The module ensures immediate and reliable actuation of alarms and control circuits, critical in industrial processes.

Product Advantages

-

Four Independent Channels: Allows monitoring of multiple conditions with independent relay actions.

-

Fast Response: Relay actuation occurs in under 10 milliseconds.

-

High Reliability: Designed to withstand industrial electrical noise and vibrations.

-

Galvanic Isolation: Each relay is isolated from logic circuits, enhancing safety.

-

Flexible Inputs: Compatible with TTL signals or dry contacts from other 3500 Series modules.

-

Compact Design: Fits standard 3500 Series rack slots.

-

Wide Operating Range: Supports operation between –20°C and +70°C.

-

High Contact Rating: Supports AC/DC loads up to 2 A.

-

Versatile Mounting: Suitable for centralized or distributed rack configurations.

-

Industrial Durability: Robust construction for harsh industrial conditions.

FAQ

-

How many relay channels are available in the 3500/32M-01 module?

The module has four independent relay channels, each capable of separate alarm or shutdown signaling. -

What type of relay contacts does the module use?

Each relay is SPDT (Single Pole Double Throw), suitable for a variety of AC and DC loads. -

What is the typical response time for relay activation?

The typical relay response time is under 10 milliseconds. -

What is the maximum current and voltage each relay can handle?

Each relay can switch up to 2 A at 30 V DC or 2 A at 250 V AC. -

Are the relay contacts isolated from the module logic?

Yes, each relay has 1500 V galvanic isolation from the module’s logic circuitry. -

Can this module interface with other 3500 Series modules?

Yes, it accepts TTL signals or dry contact inputs from compatible 3500 Series monitoring modules. -

What is the operating temperature range for this module?

It operates reliably between –20°C and +70°C. -

Is the 3500/32M-01 compatible with both centralized and distributed rack configurations?

Yes, it fits standard 3500 Series rack slots for flexible installation. -

Can each relay be used for both alarm and shutdown functions?

Yes, each channel can independently trigger alarms or shutdowns depending on monitored conditions. -

Which machinery can benefit from the 3500/32M-01 module?

It is suitable for turbines, compressors, pumps, generators, and other critical machinery requiring fast, reliable relay outputs.

Related Models (Same Series)

| Model Number | Description |

|---|---|

| 3500/32-01 | Standard 4-channel relay module |

| 3500/32-02 | 4-channel relay module with higher contact rating |

| 3500/32-03 | Relay module with diagnostic LEDs |

| 3500/32-04 | 4-channel relay module with time delay |

| 3500/32-05 | High-speed turbine optimized relay module |

| 3500/32-06 | Dual 4-channel relay module for multi-shaft systems |

Popular Models from the Same Brand (Bently Nevada)

| Model Number | Description |

|---|---|

| 3500/22 | Communication gateway for 3500 Series modules |

| 3500/42 | 4-channel vibration and position monitor |

| 3500/45M | Multi-channel machinery protection module |

| 3500/60 | Speed/phase monitor with tachometer input |

| 3300 XL | Proximity sensor for NSv and XL systems |

| 3500/40 | Machinery monitoring module with alarm outputs |

Excellent PLC

Excellent PLC