| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Overview

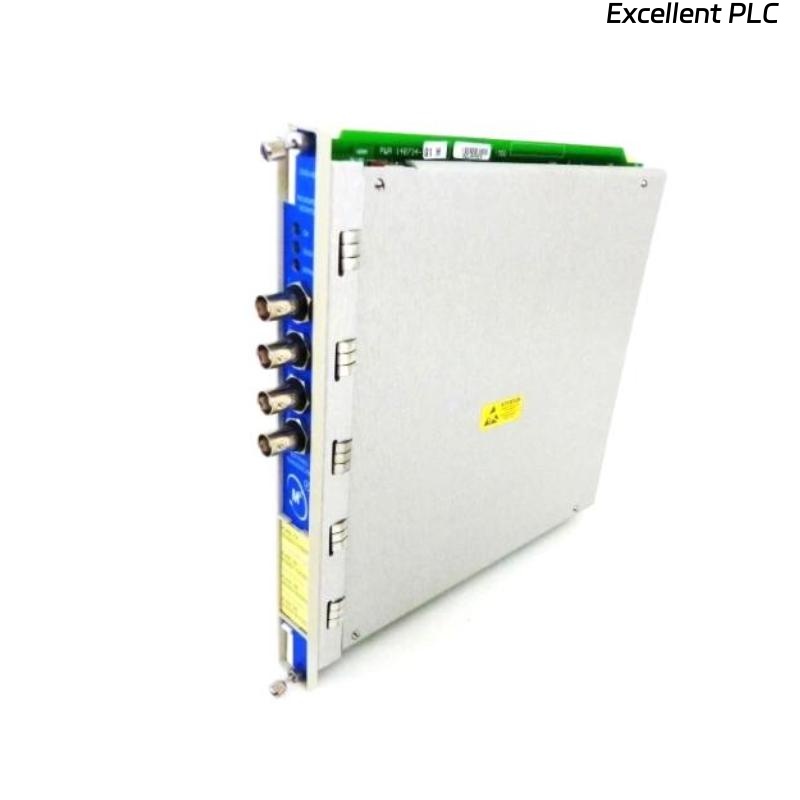

The Bently Nevada 3500/40M 140734-01 Proximitor Monitor is a four-channel monitoring module designed for machinery condition monitoring and protection. It works with proximity transducers to measure radial vibration, thrust position, differential expansion, eccentricity, and REBAM parameters. Using the 3500 Rack Configuration Software, users can configure each channel to perform up to two functions simultaneously, ensuring precise condition assessment and early fault detection in critical rotating machinery.

Technical Specifications

| Parameter | Description |

|---|---|

| Channels | 4 channels, configurable in pairs |

| Supported Measurements | Radial vibration, thrust position, eccentricity, differential expansion, REBAM |

| Power Consumption | 7.7 W typical |

| Input Impedance | 10 kΩ |

| Sensitivity | Radial Vibration/Thrust/Eccentricity: 3.94 mV/µm or 7.87 mV/µm; Differential Expansion: 0.394 mV/µm or 0.787 mV/µm; REBAM: 40 mV/µm or 80 mV/µm |

| Output Impedance | 550 Ω |

| Power Supply to Transducer | -24 Vdc |

| Accuracy | ±0.33% typical, ±1% maximum |

| Environmental | Operating: -30°C to +65°C (non-barrier), 0°C to +65°C (barrier); Storage: -40°C to +85°C; Humidity: 95% non-condensing |

| Dimensions | 241.3 x 24.4 x 241.8 mm |

| Weight | 0.91 kg |

Applications

-

Turbomachinery Monitoring – Continuous measurement of shaft vibration and position in turbines, compressors, and pumps.

-

Bearing Condition Analysis – Detection of early bearing wear using REBAM technology.

-

Thermal Expansion Monitoring – Measurement of differential expansion to prevent mechanical interference.

-

Eccentricity Detection – Monitoring rotor shape changes during start-up and operation.

-

Thrust Position Protection – Safeguarding thrust bearings from overload.

Advantages

-

Multi-Function Capability – Each channel can be independently configured for different measurement types.

-

High Accuracy – ±0.33% measurement precision for reliable machine diagnostics.

-

Programmable Alarms – User-defined alert and danger setpoints for customized protection.

-

Wide Frequency Range – Configurable filtering for various machinery speeds.

-

Global Certifications – Compliance with FCC, EMC, ATEX, IECEx, CSA, ABS, and DNV GL standards.

FAQ

Q1: What is the main function of the 3500/40M Proximitor Monitor?

A1: It measures vibration, position, and bearing conditions, providing continuous protection and diagnostics for rotating machinery.

Q2: How many channels does it support?

A2: It has 4 channels, which can be configured in pairs for different measurement types.

Q3: Can one monitor handle multiple measurement functions?

A3: Yes, it can perform up to two functions at the same time, with separate configurations for channels 1-2 and 3-4.

Q4: What type of sensors does it work with?

A4: It works with Bently Nevada proximity transducers.

Q5: How accurate are the measurements?

A5: Typical accuracy is ±0.33% of full scale, with a maximum deviation of ±1%.

Q6: Is it suitable for hazardous environments?

A6: Yes, it has hazardous area approvals for ATEX, IECEx, and CSA standards.

Q7: What is the typical operating temperature range?

A7: -30°C to +65°C for non-barrier modules and 0°C to +65°C for barrier modules.

Q8: Can the alarm settings be customized?

A8: Yes, alert and danger setpoints can be programmed via the 3500 Rack Configuration Software.

Q9: Does it have any special features for bearing monitoring?

A9: Yes, the REBAM function detects early-stage bearing wear and damage.

Q10: What industries typically use this monitor?

A10: It is widely used in power generation, oil and gas, petrochemical, and marine industries.

Related Models in the Same Series

| Model | Measurement Types | Dimensions (mm) | Weight (kg) | Function |

|---|---|---|---|---|

| 3500/42M | Proximitor & Seismic | 241.3 x 24.4 x 241.8 | 0.91 | Vibration & position monitoring |

| 3500/44M | Aeroderivative GT vibration | 241.3 x 24.4 x 241.8 | 0.91 | Gas turbine vibration monitoring |

| 3500/45 | Position | 241.3 x 24.4 x 241.8 | 0.91 | Shaft and component position measurement |

| 3500/46M | Hydro | 241.3 x 24.4 x 241.8 | 0.91 | Hydroelectric turbine monitoring |

| 3500/50 | Tachometer | 241.3 x 24.4 x 241.8 | 0.91 | Rotational speed measurement |

| 3500/60 | Temperature | 241.3 x 24.4 x 241.8 | 0.91 | Temperature monitoring for machinery |

Popular Bently Nevada Models

| Model | Measurement Types | Dimensions (mm) | Weight (kg) | Function |

|---|---|---|---|---|

| 3500/22M | Data interface | 241.3 x 24.4 x 241.8 | 0.91 | Transient data acquisition & communication |

| 3500/25 | Keyphasor | 241.3 x 24.4 x 241.8 | 0.91 | Shaft reference signal generation |

| 3500/32M | Relay | 241.3 x 24.4 x 241.8 | 0.91 | Control and shutdown relay outputs |

| 3500/34 | TMR relay | 241.3 x 24.4 x 241.8 | 0.91 | Triple modular redundancy relay protection |

| 3500/72M | Overspeed | 241.3 x 24.4 x 241.8 | 0.91 | Overspeed detection for turbines |

| 3500/93 | Display | 241.3 x 72.4 x 241.8 | 1.20 | System status and parameter display |

Excellent PLC

Excellent PLC