| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Overview

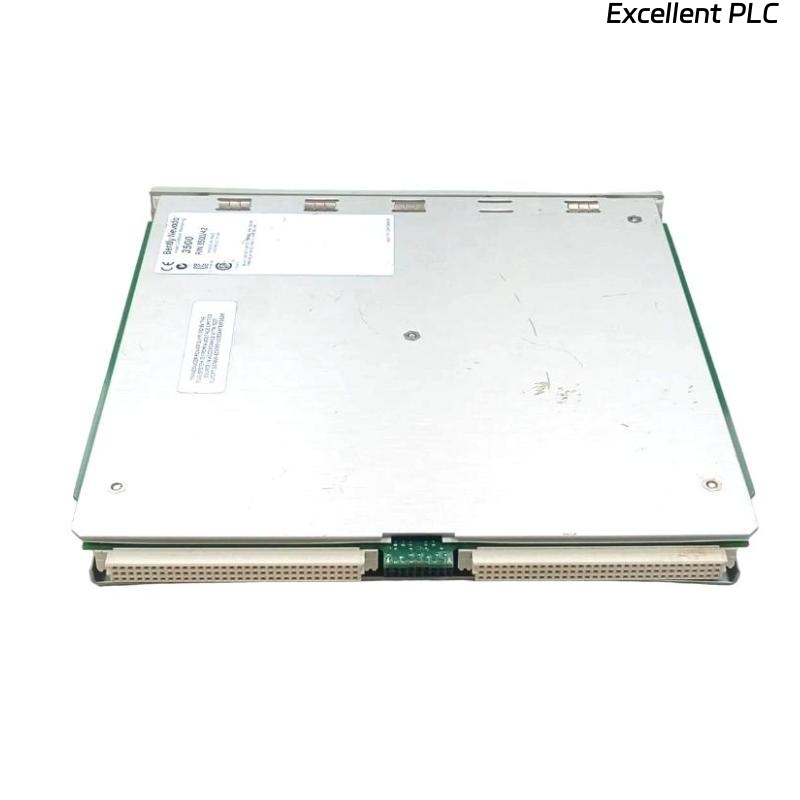

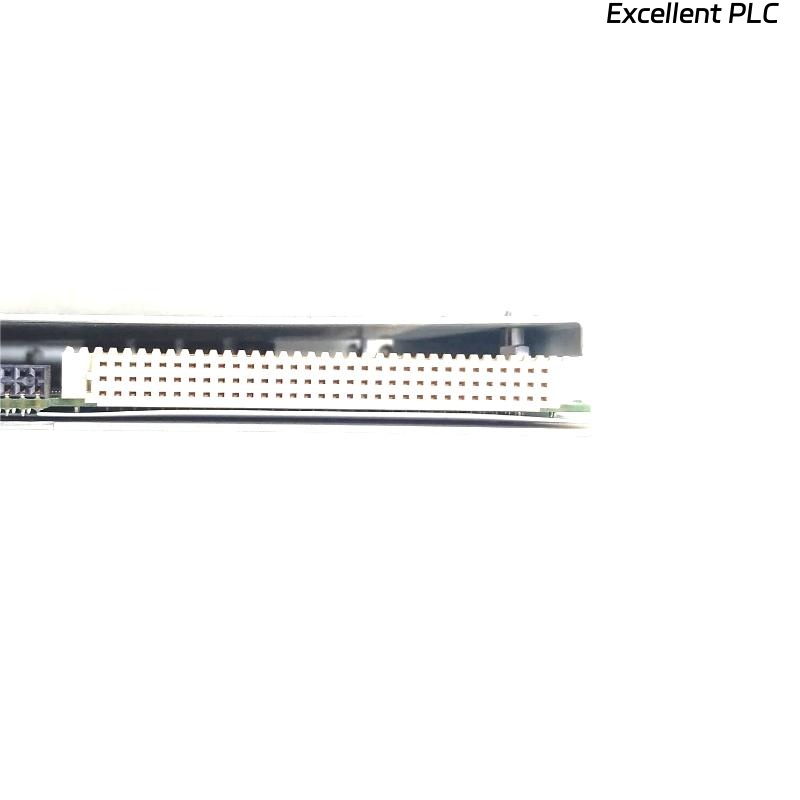

The Bently Nevada 3500/42-07-00 is a high-performance vibration monitoring module designed for industrial machinery protection and condition monitoring. It provides continuous online measurement of vibration and position parameters, enabling early detection of mechanical issues. The module integrates with the 3500 Series Machinery Protection System, offering precise proximitor and seismic signal processing with advanced filtering and alarm capabilities.

Product Parameters

| Parameter | Specification |

|---|---|

| Module Type | Proximitor/Seismic Monitor |

| Channels | 4 independent channels |

| Input Types | Proximity probes, seismic transducers |

| Measurement Range | Configurable based on sensor type |

| Signal Processing | RMS, Peak, 1X, Gap, Direct |

| Alarm Setpoints | 2 levels (Alert and Danger) per channel |

| Power Supply | Via 3500 rack backplane |

| Dimensions (W × H × D) | 241.3 × 24.4 × 241.8 mm |

| Weight | 0.91 kg |

| Operating Temperature | -30°C to +65°C |

| Compliance | CE, CSA, ATEX (varies by configuration) |

Applications

-

Rotating machinery such as turbines, compressors, pumps, and motors

-

Monitoring radial and axial vibration

-

Detecting imbalance, misalignment, and bearing wear

-

Seismic vibration monitoring in large industrial plants

-

Machinery protection in hazardous and non-hazardous areas

Product Advantages

-

High Accuracy: Advanced proximitor and seismic signal conditioning for precise measurement.

-

Multiple Input Compatibility: Supports both proximity probes and seismic transducers.

-

Advanced Alarm Logic: Dual setpoint alarms improve machine safety.

-

System Integration: Seamless compatibility with the 3500 Series rack system.

-

Robust Design: Reliable operation in harsh industrial environments.

-

Easy Configuration: Software-based parameter setup for different monitoring needs.

FAQ

-

Q: What sensors are compatible with the 3500/42-07-00?

A: It supports Bently Nevada proximity probes and seismic transducers. -

Q: Can the module measure both vibration and position?

A: Yes, it can measure displacement, velocity, and position depending on the sensor. -

Q: How many channels does it have?

A: Four independent channels. -

Q: Does it support both Alert and Danger alarms?

A: Yes, each channel has two programmable alarm setpoints. -

Q: Is it hot-swappable?

A: No, the rack must be powered down before installation or removal. -

Q: Can it be used in hazardous locations?

A: Yes, certain configurations meet ATEX and CSA standards for hazardous areas. -

Q: How is the module powered?

A: Through the 3500 Series rack backplane. -

Q: What is the accuracy of measurements?

A: It meets Bently Nevada’s high-precision standards, typically within ±1% of full-scale. -

Q: Does it require calibration?

A: It is factory-calibrated but should be checked during scheduled maintenance. -

Q: Can it log historical vibration data?

A: Historical data storage requires integration with a compatible data acquisition system.

Related Models (Same Series / Similar)

| Model | Type | Channels | Notes |

|---|---|---|---|

| 3500/42-01-00 | Proximitor/Seismic Monitor | 4 | Standard version |

| 3500/42-06-00 | Proximitor/Seismic Monitor | 4 | Alternative input range |

| 3500/40M | Proximitor Monitor | 4 | Displacement focus |

| 3500/44M | Aeroderivative Gas Turbine Monitor | 4 | Specialized for gas turbines |

| 3500/45 | Position Monitor | 4 | Shaft position measurements |

| 3500/46M | Hydro Monitor | 4 | For hydro turbines |

Popular Bently Nevada Models (Other Types)

| Model | Type | Channels | Notes |

|---|---|---|---|

| 3500/22M | Transient Data Interface | – | Data acquisition module |

| 3500/32M | Relay Module | – | Alarm relay outputs |

| 3500/60 | Temperature Monitor | 6 | For RTDs and thermocouples |

| 3500/61 | Temperature Monitor | 6 | Advanced configuration |

| 3500/65 | Velocity Monitor | 4 | Velocity transducer interface |

| 3500/72M | Overspeed Detection | – | Turbine overspeed protection |

Excellent PLC

Excellent PLC