| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

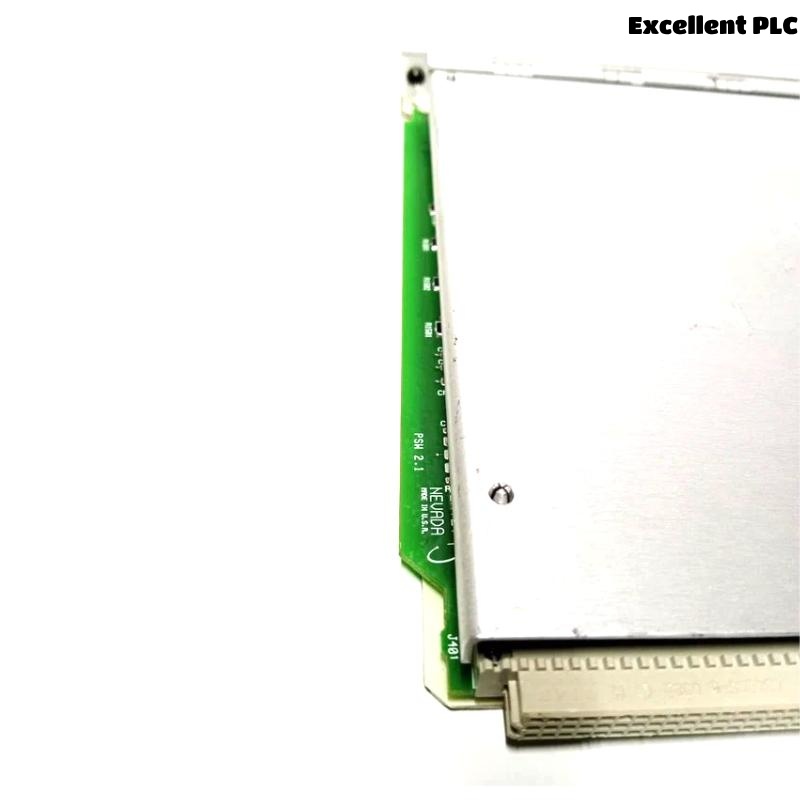

The Bently Nevada 3500/42-09-01 Proximitor Seismic Monitor, combined with hardware part numbers 176449-02 and 140471-01, is a dual-channel vibration and seismic monitoring module engineered for the 3500 Series Machinery Protection System. Developed by Bently Nevada, a world leader in asset condition monitoring, this advanced module is specifically designed to process input signals from proximity and seismic transducers, converting them into meaningful outputs used for critical machinery protection and diagnostics.

Ideal for high-performance rotating equipment, such as turbines, compressors, motors, and pumps, this module enables plant operators to continuously monitor asset conditions and detect anomalies early. The result is improved equipment reliability, reduced maintenance costs, and enhanced safety.

Product Specifications

| Parameter | Specification |

|---|---|

| Model Number | 3500/42-09-01 |

| Part Numbers | 176449-02 + 140471-01 |

| Product Type | Proximitor® Seismic Monitor Module |

| Manufacturer | Bently Nevada (GE Measurement & Control) |

| Monitoring Channels | 2 channels (independent or correlated monitoring) |

| Input Type | Proximitor proximity probes and seismic sensors |

| Output Signal | Buffered BNC, 4–20 mA current loop, alert and danger alarms |

| Power Supply | Supplied by the 3500 Rack (nominal 24 VDC) |

| Operating Temp. | -20°C to +70°C |

| Storage Temp. | -40°C to +85°C |

| Humidity Range | 0–95% RH, non-condensing |

| Mounting Style | 3500 Rack-mounted, 19-inch standard |

| Dimensions (HxWxD) | 241.3 x 24.4 x 241.8 mm |

| Weight | 0.91 kg |

| Compliance | CE, UL, CSA, RoHS compliant |

Product Applications

The Bently Nevada 3500/42-09-01 module is engineered for continuous protection and predictive diagnostics of critical mechanical assets in demanding industrial environments. Its typical applications include:

-

Power Generation: For continuous monitoring of turbine bearings and shaft alignment conditions.

-

Oil & Gas Facilities: Protecting compressors, gearboxes, and rotating pumps from excessive vibration.

-

Chemical & Petrochemical Industries: Monitoring vibration in rotating and reciprocating equipment.

-

Mining and Heavy Industry: Ensuring operational integrity of crushers, mills, and large gearboxes.

-

Marine and Offshore Platforms: For structural seismic monitoring and rotating machinery health diagnostics.

-

Aerospace Test Facilities: Used for precision vibration measurement in engine and test stand applications.

Product Advantages

-

Dual-Channel Monitoring: Monitors two vibration or seismic inputs independently or in correlation, reducing space and hardware costs.

-

High Signal Fidelity: Delivers accurate signal processing and conditioning for true machinery diagnostics.

-

Buffered Output: Provides real-time sensor signal access via BNC connectors for portable analyzers.

-

Alarm Integration: Configurable alert and danger setpoints ensure real-time protection action.

-

Reliability in Harsh Environments: Withstands wide operating temperature and humidity ranges.

-

Easy Rack Integration: Seamlessly installs into Bently Nevada’s modular 3500 Series monitoring racks.

-

Early Fault Detection: Identifies imbalance, misalignment, looseness, or bearing wear before failure.

-

Broad Sensor Compatibility: Works with a wide range of Bently Nevada proximity and seismic transducers.

-

Regulatory Compliance: Certified to meet international standards for electrical and process industry use.

-

Modular and Scalable: Ideal for both small-scale and plant-wide monitoring installations.

Frequently Asked Questions (FAQ)

-

What types of sensors are compatible with the 3500/42-09-01?

This module supports Proximitor proximity probes and seismic sensors from Bently Nevada. -

Can this monitor detect both vibration and displacement?

Yes. It processes signals from proximity sensors (displacement) and seismic probes (vibration/velocity). -

Is this module compatible with other 3500 Series modules?

Absolutely. It integrates seamlessly with all other modules in the 3500 Rack system. -

How many input channels does it have?

It has two independent channels, allowing for flexible monitoring configurations. -

Does it include built-in alarms?

Yes. Each channel supports configurable alert and danger setpoints with relay outputs through the system. -

How do I retrieve real-time data?

Buffered BNC outputs on the front panel allow you to connect a portable analyzer for real-time data retrieval. -

What kind of diagnostics can it support?

It detects imbalance, shaft misalignment, bearing degradation, and structural resonance. -

Is the module hot-swappable?

Yes, it can be replaced without powering down the rack, minimizing downtime. -

Is external software needed for configuration?

Yes, configuration is performed using Bently Nevada’s 3500 Configuration Software. -

How does it help with predictive maintenance?

By continuously monitoring vibration and displacement, it enables trending, early fault detection, and proactive maintenance decisions.

Recommended Related Models (Same Series or Closely Related)

| Model Number | Description | Function | Dimensions (mm) | Weight (kg) |

|---|---|---|---|---|

| 3500/42-01-00 | Standard Proximitor Seismic Monitor | Dual-channel proximity/vibration | 127 × 50 × 210 | 0.75 |

| 3500/42-04-00 | Enhanced Seismic Monitor | Vibration with advanced diagnostics | 127 × 50 × 210 | 0.75 |

| 3500/44 | Velocity Monitor | Velocity signal conditioning | 127 × 50 × 210 | 0.72 |

| 3500/20 | Monitoring System Interface | Signal interface and relay output | 127 × 50 × 210 | 0.74 |

| 3500/45 | Acceleration Monitor | High-frequency vibration monitoring | 127 × 50 × 210 | 0.76 |

| 3500/40 | Displacement Monitor | Shaft displacement and position | 127 × 50 × 210 | 0.73 |

Popular Bently Nevada Models (Same Brand)

| Model Number | Description | Application | Dimensions (mm) | Weight (kg) |

|---|---|---|---|---|

| 3300 XL Series | Vibration Monitoring System | General industrial machinery | Varies | Varies |

| 3500/22M | Transient Data Interface | Transient signal capture and export | 127 × 50 × 210 | 0.78 |

| 3500/61 | Overspeed Detection Module | Speed protection in turbines | 127 × 50 × 210 | 0.70 |

| 3500/55 | Position and Phase Monitor | Shaft phase and axial position | 127 × 50 × 210 | 0.80 |

| 3500/15 | Power Supply Module | Supplies DC power to 3500 rack | 127 × 50 × 210 | 0.75 |

| 3500/92 | Communication Gateway Module | Network and control system interface | 127 × 50 × 210 | 0.70 |

Excellent PLC

Excellent PLC