| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

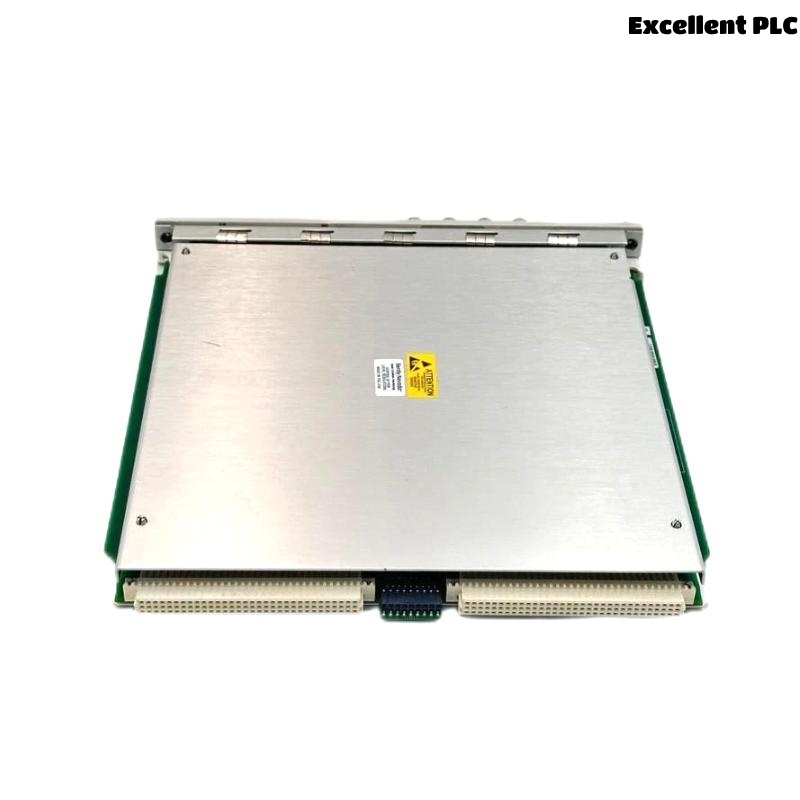

The Bently Nevada 3500/42-09-02 Proximitor Seismic Monitor is a dual-channel monitoring module engineered for vibration and seismic data acquisition in the 3500 Series Machinery Protection System. It is designed to receive input from proximity probes and seismic transducers, converting these raw sensor signals into actionable data for protection and monitoring of critical rotating equipment.

Associated with part numbers 140734-02 (monitor module) and 140471-01 (I/O module), the 3500/42-09-02 provides buffered outputs, alert and danger setpoints, and 4–20 mA current loop integration. It is a critical solution for industries where equipment reliability, predictive maintenance, and real-time diagnostics are essential. This module supports highly accurate detection of vibration and displacement anomalies, enabling proactive responses that help prevent unplanned downtime and expensive repairs.

Product Specifications

| Parameter | Specification |

|---|---|

| Model Number | 3500/42-09-02 |

| Part Numbers | 140734-02 + 140471-01 |

| Monitoring Channels | Dual-channel (independent or paired) |

| Sensor Compatibility | Proximitor proximity probes, seismic transducers |

| Input Signal Types | Displacement (proximity), Velocity (seismic) |

| Output Options | Buffered BNC, 4–20 mA current loop, alert/danger signals |

| Power Source | Supplied via Bently Nevada 3500 rack (24 VDC) |

| Mounting Method | 19” rack-mount (within 3500 system) |

| Operating Temperature | -20°C to +70°C |

| Storage Temperature | -40°C to +85°C |

| Humidity Range | 0–95% non-condensing |

| Compliance Standards | CE, UL, CSA, RoHS |

| Dimensions (HxWxD) | 241.3 x 24.4 x 241.8 mm |

| Weight | 0.91 kg |

Product Applications

The 3500/42-09-02 Proximitor Seismic Monitor is a cornerstone in a wide range of industrial applications requiring real-time asset condition monitoring:

-

Power Generation: Monitoring of turbines, generators, and shaft alignment.

-

Oil & Gas Facilities: Tracking vibration on compressors, motors, pumps, and fans.

-

Chemical and Petrochemical Plants: Continuous monitoring of rotating and reciprocating machinery.

-

Mining Operations: Measuring structural vibration and equipment health under high-load conditions.

-

Offshore Platforms: Suitable for detecting low-frequency structural vibration and mechanical imbalance.

-

Manufacturing Industries: Ensures reliability of conveyors, mixers, and large-scale rotating equipment.

In all these applications, it enhances the ability to forecast mechanical issues and perform maintenance only when necessary, thereby improving efficiency and safety.

Product Advantages

-

Accurate Dual-Channel Monitoring: Allows independent or comparative monitoring of two channels to optimize diagnostics.

-

Real-Time Protection: Alerts and danger relay outputs support rapid decision-making and automatic shutdown of equipment.

-

Buffered Outputs for Analysis: Easily interface with portable data analyzers for advanced diagnostics and troubleshooting.

-

Predictive Maintenance Support: Enables condition-based maintenance strategies instead of reactive servicing.

-

Built-in Alarm Configuration: Offers adjustable alarm thresholds to respond to specific operating requirements.

-

Seamless System Integration: Part of the modular 3500 Series, ensuring compatibility with other Bently Nevada modules.

-

Environmentally Robust: Operates reliably across wide temperature and humidity ranges in industrial settings.

-

Field-Proven Reliability: Trusted in thousands of industrial applications globally for continuous protection.

-

Comprehensive Output Options: Supports both digital and analog output, accommodating legacy and modern control systems.

-

Quick Replacement and Maintenance: Hot-swappable design allows replacement without shutting down the system.

Frequently Asked Questions (FAQ)

-

What type of sensors can be used with the 3500/42-09-02?

It is compatible with Bently Nevada’s Proximitor proximity probes and seismic sensors. -

Can I monitor two separate machines with this module?

Yes, each channel operates independently, allowing monitoring of two separate assets or locations. -

What outputs are available from this module?

Buffered signal output (BNC), 4–20 mA current loop, and alarm relays (via rack). -

Is it compatible with SCADA or DCS systems?

Yes, analog output and relay signals can be integrated with plant-wide control systems. -

Does this model support hot swapping?

Yes, it can be removed and replaced without powering down the 3500 rack. -

What software is required for configuration?

Bently Nevada 3500 Configuration Software is used for parameter setup and diagnostics. -

What’s the main difference between 3500/42-09-02 and 3500/42-09-01?

The -02 model may include updated firmware or minor internal adjustments—consult the datasheet for specific revisions. -

How long is the module’s operational life?

With regular maintenance, modules often function reliably for 10+ years in industrial environments. -

Can I use this module for shutdown protection?

Yes, it provides configurable alarms and works with shutdown relays to prevent machinery damage. -

Is this module suitable for hazardous environments?

It can be used in hazardous areas when installed in certified enclosures with proper protection methods.

Recommended Related Models (Same Series or Closely Related)

| Model Number | Description | Function | Dimensions (mm) | Weight (kg) |

|---|---|---|---|---|

| 3500/42-01-00 | Proximitor Seismic Monitor | Basic dual-channel vibration monitor | 127 × 50 × 210 | 0.75 |

| 3500/42-04-00 | Advanced Seismic Monitor | Improved diagnostics for seismic inputs | 127 × 50 × 210 | 0.75 |

| 3500/42-09-00 | Proximitor Monitor | Standard dual-channel with buffered outputs | 127 × 50 × 210 | 0.75 |

| 3500/40 | Proximitor Displacement Monitor | Shaft displacement measurement | 127 × 50 × 210 | 0.73 |

| 3500/44 | Velocity Monitor Module | Velocity signal monitoring | 127 × 50 × 210 | 0.72 |

| 3500/45 | Acceleration Monitor | High-frequency vibration analysis | 127 × 50 × 210 | 0.76 |

Popular Bently Nevada Models (Same Brand)

| Model Number | Description | Application | Dimensions (mm) | Weight (kg) |

|---|---|---|---|---|

| 3300 XL Series | Vibration Monitoring System | General rotating equipment monitoring | Varies | Varies |

| 3500/22M | Transient Data Interface | Data capture and event logging | 127 × 50 × 210 | 0.78 |

| 3500/15 | Power Supply Module | Powers entire 3500 rack | 127 × 50 × 210 | 0.75 |

| 3500/61 | Overspeed Detection Module | Speed protection | 127 × 50 × 210 | 0.70 |

| 3500/92 | Communication Gateway Module | Modbus/Network communication | 127 × 50 × 210 | 0.70 |

| 3500/55 | Phase and Position Monitor | Shaft position and phase detection | 127 × 50 × 210 | 0.80 |

Excellent PLC

Excellent PLC