| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

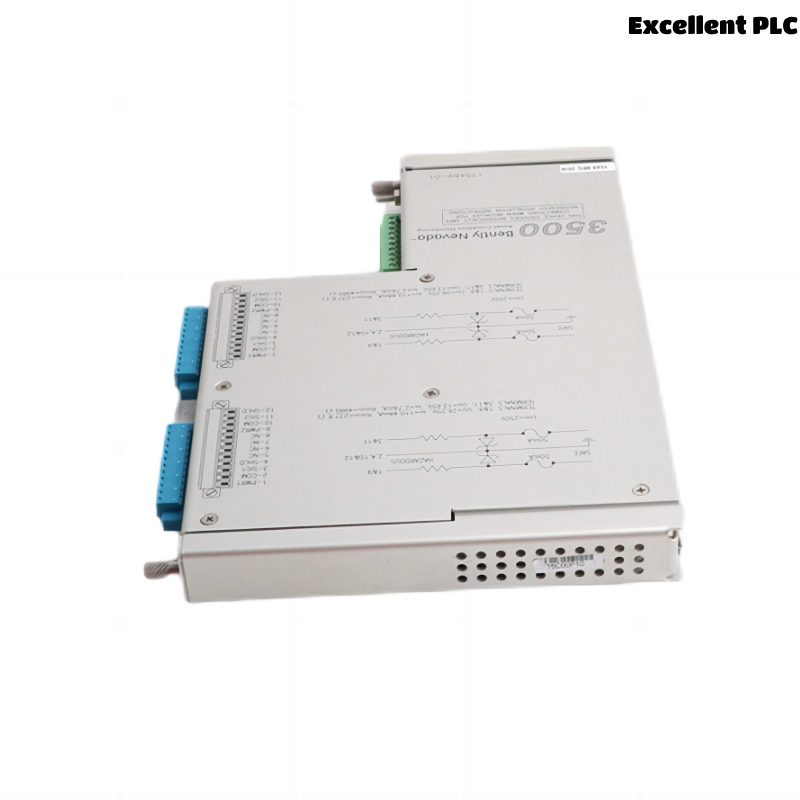

The Bently Nevada 3500/42M-04-00 135489-01 is a seismic monitoring I/O module used in industrial machinery monitoring systems. This module is designed for high-performance vibration and seismic monitoring, ensuring early detection of equipment anomalies and potential faults. By integrating seismic sensors into control systems, the 3500/42M module enables real-time monitoring of machine health, improving overall system reliability and uptime.

The 3500/42M-04-00 module is part of the Bently Nevada 3500 series, known for its high-precision measurement and ease of integration into existing systems. With advanced features for signal conditioning, processing, and analysis, the module can detect even minor seismic activity, making it a valuable tool in industries such as power generation, oil & gas, and manufacturing. It is particularly essential in environments where early detection of machine misalignment, imbalance, or other mechanical issues can prevent major failures and costly downtime.

Product Parameters

| Parameter | Value |

|---|---|

| Dimensions (L x W x H) | 241.3 × 24.4 × 163.1 mm |

| Weight | 0.46 kg |

| Operating Voltage | 24 V DC |

| Seismic Frequency Range | 0.1 Hz to 10 kHz |

| Signal Output | 4-20 mA, 0-10 V |

| Temperature Range | -40°C to +85°C |

| Mounting Type | Rail-mounted |

| Input Type | Differential / Single-ended |

| Compliance | CE, UL certified |

Applications

The Bently Nevada 3500/42M-04-00 seismic monitoring I/O module is designed for a range of critical industrial applications, including:

-

Machinery Monitoring: Continuously monitors vibrations and seismic activity in rotating machinery, providing early warnings of mechanical issues such as misalignment, imbalance, and bearing failure.

-

Power Generation: Used in power plants to monitor the health of critical machinery such as turbines, compressors, and pumps, ensuring continuous operation and minimizing unplanned shutdowns.

-

Oil & Gas: In offshore and onshore oil rigs, the module helps monitor seismic activity and machinery conditions, enabling proactive maintenance and ensuring the safe operation of equipment in harsh conditions.

-

Mining: Used in mining operations to monitor the seismic vibrations of equipment such as crushers and conveyor systems, preventing potential failures that could cause costly delays.

-

Manufacturing: Helps maintain the health of industrial machinery, including motors, gearboxes, and conveyors, by detecting anomalies early and preventing downtime.

-

Marine: Applied in the monitoring of seismic activity in marine vessels, where vibration data can predict the failure of essential systems such as pumps and engines.

Advantages

-

High Precision Monitoring: The 3500/42M-04-00 module provides highly accurate seismic data to ensure the early detection of faults, improving overall equipment reliability and reducing downtime.

-

Wide Frequency Range: The module’s frequency range (0.1 Hz to 10 kHz) allows it to detect both low-frequency and high-frequency seismic activity, making it suitable for a broad spectrum of industrial applications.

-

Flexible Output Options: With both 4-20 mA and 0-10 V output options, the module is compatible with a wide variety of control and monitoring systems.

-

Temperature Resilience: The 3500/42M-04-00 module operates effectively across a wide temperature range of -40°C to +85°C, making it suitable for extreme industrial environments.

-

Compact and Easy to Install: With compact dimensions and rail-mounting capability, the module can be easily integrated into existing systems with minimal space requirements.

-

Signal Conditioning: The module provides effective signal conditioning, ensuring that seismic data is clean and reliable, enabling accurate fault detection and system diagnostics.

-

Enhanced Reliability: By continuously monitoring vibrations and seismic activity, the module reduces the risk of catastrophic failures, extends the life of machinery, and ensures continuous operation.

FAQs

-

What is the frequency range of the Bently Nevada 3500/42M-04-00 module?

The module supports a seismic frequency range of 0.1 Hz to 10 kHz. -

What is the weight of the 3500/42M-04-00 module?

The module weighs 0.46 kg. -

What output options does the 3500/42M-04-00 module support?

The module supports 4-20 mA and 0-10 V output options for seamless integration with control systems. -

What is the operating temperature range of the module?

The module operates in a temperature range from -40°C to +85°C. -

What industries can benefit from the 3500/42M-04-00 seismic monitoring module?

It is suitable for use in power generation, oil & gas, mining, manufacturing, and marine industries, among others. -

How is the module mounted?

The module is designed for rail mounting, making it easy to integrate into existing systems. -

What is the input type of the 3500/42M-04-00 module?

It supports both differential and single-ended inputs for flexibility. -

Is the Bently Nevada 3500/42M-04-00 module certified?

Yes, the module is CE and UL certified, ensuring it meets international safety and quality standards. -

Can the 3500/42M-04-00 module detect low-frequency vibrations?

Yes, the module can detect seismic activity in the low-frequency range starting from 0.1 Hz. -

How does the 3500/42M-04-00 module improve equipment reliability?

By continuously monitoring seismic and vibration data, the module helps detect faults early, preventing major failures and reducing downtime.

Recommended Models (Same Series or Related Models)

| Model | Description | Dimensions (L x W x H) | Weight |

|---|---|---|---|

| 3500/42M | Seismic monitoring module | 241.3 × 24.4 × 163.1 mm | 0.46 kg |

| 3500/41 | Vibration monitoring module | 241.3 × 24.4 × 163.1 mm | 0.46 kg |

| 3500/44 | Dynamic vibration monitor | 241.3 × 24.4 × 163.1 mm | 0.46 kg |

| 3500/45 | Rotor monitoring module | 241.3 × 24.4 × 163.1 mm | 0.46 kg |

| 3500/46 | Expansion module for seismic monitoring | 241.3 × 24.4 × 163.1 mm | 0.46 kg |

| 3500/47 | Temperature and vibration module | 241.3 × 24.4 × 163.1 mm | 0.46 kg |

Popular Bently Nevada Models

| Model | Description | Dimensions (L x W x H) | Weight |

|---|---|---|---|

| 3300 XL | Proximity sensor | 96.5 × 25.4 × 25.4 mm | 0.5 kg |

| 3300 | Vibration sensor | 100 × 50 × 50 mm | 0.6 kg |

| 330010-00-02 | Seismic sensor | 100 × 50 × 50 mm | 0.6 kg |

| 3500/22 | Monitor for vibration | 241 × 244 × 164 mm | 0.8 kg |

| 3500/50 | Monitoring module | 241 × 244 × 164 mm | 0.8 kg |

| 3500/53 | Accelerometer module | 241 × 244 × 164 mm | 0.8 kg |

Excellent PLC

Excellent PLC